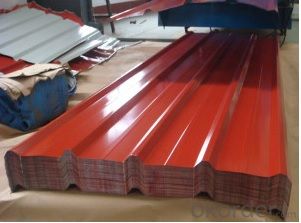

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Brief Introduction

COLD ROLLED WAVE GALVANIZED STEEL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q:What are the different sheet metal finishing techniques for steel sheets?

- Some of the different sheet metal finishing techniques for steel sheets include deburring, grinding, polishing, sanding, and painting.

- Q:Can steel sheets be used for electrical conductivity applications?

- No, steel sheets are not typically used for electrical conductivity applications. While steel is a good conductor of heat and has some electrical conductivity, it is not as efficient as other materials specifically designed for electrical conductivity, such as copper or aluminum. Steel sheets are commonly used in applications where strength, durability, and corrosion resistance are important, such as construction, automotive manufacturing, and industrial equipment. For electrical conductivity applications, it is more common to use materials with higher conductivity, such as copper or aluminum. These materials have lower resistance and are better suited for conducting electricity efficiently.

- Q:Can the steel sheets be used for fencing or security purposes?

- Certainly! Fencing or security purposes can indeed be fulfilled by employing steel sheets. Given their robustness and durability, steel sheets find widespread application in the construction of fences and security barriers. These sheets offer a solid and impregnable barricade, rendering them ideal for safeguarding high-security zones like prisons, military bases, and industrial complexes. Moreover, steel sheets can be tailored to meet specific fencing requirements, providing a plethora of designs and varying heights. Furthermore, the material's resistance against corrosion ensures enduring defense against environmental factors, thereby establishing it as a dependable option for fencing and security purposes.

- Q:What is the average thermal conductivity of steel sheets?

- The average thermal conductivity of steel sheets typically ranges from 15 to 50 Watts per meter Kelvin (W/m·K).

- Q:1.5mm galvanized steel prices?

- 1.5mm galvanized steel plate price between 4500-6000 yuan.

- Q:What are the different testing methods for steel sheets?

- There are several testing methods for steel sheets, including visual inspection, hardness testing, tensile testing, impact testing, bend testing, and ultrasonic testing. Visual inspection involves examining the surface for any visible defects or imperfections. Hardness testing measures the resistance of the steel to indentation, which can indicate its strength and durability. Tensile testing evaluates the steel's ability to withstand pulling forces, while impact testing measures its resistance to sudden shocks or impacts. Bend testing assesses the steel's flexibility and ability to withstand deformation. Ultrasonic testing uses sound waves to detect internal flaws or defects in the steel. These methods are commonly used to ensure the quality and reliability of steel sheets in various industries.

- Q:What are the cost considerations for steel sheets?

- The cost considerations for steel sheets typically depend on factors such as the grade of steel, size and thickness of the sheets, quantity required, and market conditions. Additionally, transportation and handling costs, as well as any additional processing or finishing requirements, can also impact the overall cost of steel sheets.

- Q:What is the average thickness of galvanized steel sheets?

- The average thickness of galvanized steel sheets typically ranges from 0.8mm to 3mm, depending on the specific application and industry standards.

- Q:Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications. Steel is a good conductor of electricity, which makes it an ideal material for various electrical components and applications. It can be used for electrical enclosures, panels, cabinets, and other infrastructure where electrical equipment is housed. Steel sheets are also commonly used for grounding systems, electrical connectors, and electrical appliances. Additionally, steel sheets can provide durability and protection against environmental factors, such as corrosion or fire, which are important considerations in electrical applications.

- Q:What are the safety considerations when working with steel sheets?

- When working with steel sheets, some safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against cuts, burns, and falling objects. It is important to handle steel sheets with caution to avoid injury from sharp edges or corners. Additionally, ensuring proper ventilation in the work area is important to minimize exposure to potentially harmful fumes or dust particles. Regularly inspecting equipment and tools for any defects or damages is crucial to prevent accidents. Finally, following proper lifting techniques and using mechanical aids when necessary can help prevent strains or other musculoskeletal injuries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords