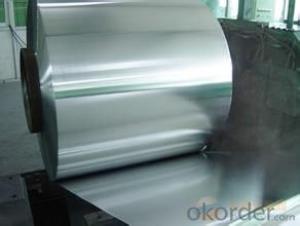

cold rolled steel coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Images:

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: How are steel coils packaged for transportation?

- Steel coils are typically packaged for transportation by wrapping them tightly with steel straps or bands to secure them in place. The coils are usually placed on wooden pallets or skids for easy handling and loading onto trucks or shipping containers. Additionally, protective materials such as cardboard or plastic edge protectors may be used to prevent damage to the coils during transportation.

- Q: How are steel coils uncoiled?

- Steel coils are uncoiled using a mechanical process called decoiling, where the coil is placed on a mandrel and then unwound using a motor-driven system. The coil is pulled through a set of straightening rolls to ensure it is properly aligned and then fed into the production line for further processing or fabrication.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Steel shafts will provide more accuracy, but they are much heavier than graphite (obviously). They have extremely low torque ratios which allows them to be more accurate. However, you need to have a very fast, controlled swing to be successful with steel shafted woods. Notice that only a few PGA Tour pros have them.

- Q: What are the challenges in coil recoiling?

- Some of the challenges in coil recoiling include achieving precise and consistent coiling, minimizing coil distortion and tangling, preventing material damage or breakage during recoiling, and ensuring efficient and safe handling of coiled materials. Additionally, factors such as coil size, weight, and material properties can also pose challenges in the recoiling process.

- Q: What are the common coil grades available for steel coils?

- There are several common coil grades available for steel coils, each with its own specific properties and applications. Some of the most commonly used coil grades include: 1. Hot Rolled Coils (HRC): This grade is produced by heating a slab of steel above its recrystallization temperature and then rolling it into a coil. HRC coils are known for their excellent weldability and formability, making them suitable for a wide range of applications such as construction, automotive manufacturing, and general engineering. 2. Cold Rolled Coils (CRC): These coils are produced by further processing hot rolled coils through cold reduction, which involves passing the steel through a series of rollers at room temperature. CRC coils have superior surface finish and dimensional accuracy, making them ideal for applications that require a smooth and uniform appearance, such as automotive body panels, appliances, and electrical equipment. 3. Galvanized Coils (GI): Galvanized steel coils are created by coating regular carbon steel coils with a layer of zinc through a hot-dip galvanizing process. This provides excellent corrosion resistance, making GI coils suitable for outdoor applications like roofing, fencing, and structural components. 4. Stainless Steel Coils: Stainless steel coils are manufactured from a variety of grades, with the most common being austenitic (such as 304 and 316) and ferritic (such as 430). Stainless steel coils offer excellent corrosion resistance, high temperature resistance, and aesthetic appeal, making them widely used in industries like food processing, chemical processing, and architecture. 5. Electro-galvanized Coils (EG): Electro-galvanized coils are similar to GI coils, but the zinc coating is applied using an electrolytic process instead of hot-dipping. EG coils have a thinner and smoother zinc layer, making them suitable for applications that require a brighter and more aesthetic appearance, such as automotive parts, appliances, and decorative items. These are just a few of the common coil grades available for steel coils. The selection of the appropriate grade depends on factors such as the intended application, required mechanical properties, and desired aesthetics. It is important to consult with steel suppliers or industry experts to determine the most suitable coil grade for a specific application.

- Q: How are steel coils used in the production of wind turbine components?

- Wind turbine components rely heavily on steel coils for their production. These coils, typically crafted from high-strength steel, possess remarkable durability and resilience against harsh weather conditions. The tower, which serves as the wind turbine's main support structure, heavily relies on steel coils. These coils are used to construct the tower sections, which are then assembled to create a sturdy and tall structure capable of withstanding the weight of the nacelle and rotor blades. Steel coils also find essential application in the manufacturing of the rotor blades. Responsible for capturing wind energy and converting it into rotational motion, the rotor blades require a strong internal structure called the spar, which is constructed using steel coils. These coils are shaped and formed to achieve the desired blade shape, with composite materials added to enhance aerodynamic properties. Moreover, steel coils are utilized in the production of other wind turbine components like the hub and the nacelle. The hub, located at the center of the rotor, demands a robust steel structure to endure the immense forces generated by the rotating blades. The nacelle, which houses crucial turbine components such as the generator, also incorporates steel coils in its construction to ensure stability and protection. To summarize, steel coils play a vital role in the production of wind turbine components. From the tower to the rotor blades, hub, and nacelle, these coils provide the necessary strength, durability, and stability required to withstand the demanding conditions of wind energy production. Without them, the construction and operation of wind turbines would be impossible, as they serve as the backbone of these renewable energy systems.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry are coil cradles, coil reels, coil straighteners, coil feeders, and coil transfer cars. These tools are essential for safe and efficient handling of coiled materials during various manufacturing processes.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Great answer by JayDub. Amazon isn't exactly a great site for legitimate sword shopping. Look for legitimate retailers specializing in handmade swords.

- Q: What are the challenges in welding steel coils?

- Some challenges in welding steel coils include potential distortion due to heat, ensuring consistent and strong welds along the entire length, managing the high temperatures involved, and avoiding defects such as porosity or cracking. Additionally, the large size and weight of the coils can pose logistical challenges for handling and positioning during the welding process.

- Q: What really is the difference between stain-less steel and iron? I only know that iron is an element, and stain-less steel is an alloy...but what else is there?

- Steel is iron that is treated with very specific amounts of carbon (sometimes other specific elements are added which results in different types of steel alloy) which results in greatly increased utility in all aspects of the metal.

Send your message to us

cold rolled steel coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords