Alloy Aluminum Coil 3000 Series Cold Rolled Aluminum Coils 1050 1060 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold rolled aluminum coils 1050 1060 1100

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Cold rolled aluminum coils 1050 1060 1100

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold rolled aluminum coils 1050 1060 1100

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

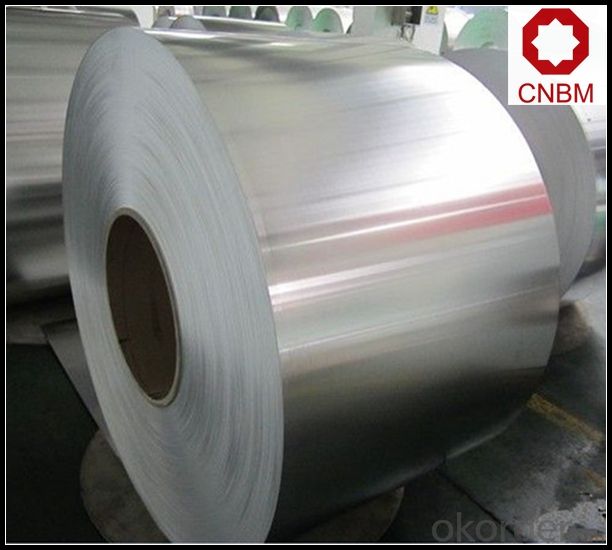

5. Image of Cold rolled aluminum coils 1050 1060 1100

6. Package and shipping of Cold rolled aluminum coils 1050 1060 1100

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: It's time for a new bike and I don't know enough about the pros and cons of aluminum vs. carbon fiber. I can get a low-end carbon bike or a high-end aluminum for about the same price, so the budget is not really a major issue. Any opinions would be appreciated.

- carbon is normally lighter but i would prefer the high end aluminum

- Q: Are aluminum coils suitable for insulation jacketing?

- Yes, aluminum coils are suitable for insulation jacketing. Aluminum is a popular choice for jacketing material due to its excellent thermal properties, durability, and corrosion resistance. It is widely used in various industries, including HVAC, oil and gas, and petrochemical, for insulating pipe systems and equipment. Aluminum coils provide a protective covering around insulation materials, preventing moisture ingress and maintaining thermal efficiency. Additionally, their lightweight nature makes them easy to install and transport. Overall, aluminum coils are a reliable and effective solution for insulation jacketing applications.

- Q: How are aluminum coils protected during shipping?

- Aluminum coils are protected during shipping through various methods to ensure their safety and prevent any damage. One common method is the use of protective packaging materials such as bubble wrap, foam, or corrugated cardboard. These materials are used to wrap the coils and create a cushioning effect, absorbing any impact or vibration that may occur during transportation. In addition to protective packaging materials, aluminum coils are often placed in sturdy shipping containers or crates. These containers are designed to provide extra security and stability during transit, minimizing the risk of the coils being jostled or bumped. Moreover, in some cases, aluminum coils are secured with strapping or banding to keep them in place and prevent shifting or movement during transportation. This helps to maintain the integrity of the coils and minimize the risk of damage caused by rubbing against other objects. Furthermore, shipping companies may also use air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This further reduces movement and provides an additional layer of protection for the coils. Overall, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their destination.

- Q: How do aluminum coils contribute to energy-efficient HVAC systems?

- Aluminum coils contribute to energy-efficient HVAC systems by their superior heat transfer capabilities. The high thermal conductivity of aluminum allows for efficient heat exchange, enabling the HVAC system to cool or heat the air more effectively. Additionally, aluminum coils are lightweight and corrosion-resistant, which increases the system's durability and reduces maintenance costs. Overall, using aluminum coils in HVAC systems helps optimize energy usage and improve overall efficiency.

- Q: How do aluminum coils contribute to noise reduction?

- Aluminum coils contribute to noise reduction primarily due to their ability to absorb and dampen vibrations. When installed in various applications, such as in HVAC systems or automotive components, the aluminum coils help to minimize the transfer of sound waves by absorbing and dissipating the energy created by vibrations. This helps to reduce overall noise levels, creating a quieter and more comfortable environment.

- Q: What are the different thicknesses available for aluminum coils?

- Aluminum coils are available in various thicknesses to cater to different application requirements. The thickness options typically range from 0.2mm to 6mm. The specific thickness needed depends on the intended use of the aluminum coil. Thinner coils, such as those with a thickness of 0.2mm to 1mm, are often used in electronics, packaging, and building materials where flexibility and lightweight properties are important. Medium thickness coils, ranging from 1mm to 3mm, are commonly employed in automotive parts, roofing, and cladding applications. On the other hand, thicker aluminum coils, with a thickness of 3mm to 6mm, are utilized in heavy-duty industrial applications like shipbuilding, aerospace, and construction. It is important to consider the specific requirements and intended use of the aluminum coil to determine the most suitable thickness for the desired application.

- Q: This question asks about the impact of aluminum coils on safety and health protection during welding processes.

- <p>Aluminum coils can significantly affect welding safety and health protection due to their unique properties. Aluminum is lighter than steel and conducts heat quickly, which can lead to faster heat transfer to the welder, increasing the risk of burns. Additionally, aluminum welding produces fumes that contain aluminum oxide, which can be harmful if inhaled over time, potentially causing respiratory issues or even neurological damage. Welders must use proper ventilation and respiratory protection to mitigate these risks. Moreover, aluminum's high reflectivity can cause intense light exposure, necessitating the use of appropriate eye protection to prevent eye injuries. Overall, aluminum welding requires specific safety measures to protect welders' health and safety.</p>

- Q: Can aluminum coils be used in the production of military equipment?

- Yes, aluminum coils can be used in the production of military equipment. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various military applications, such as aircraft components, armored vehicles, and weapon systems. Its strength to weight ratio and ability to withstand harsh environments make it an ideal choice for military equipment manufacturing.

- Q: What are the different surface finishes for pre-painted aluminum coils?

- Pre-painted aluminum coils offer a variety of surface finishes to enhance their appearance, durability, and resistance to external factors. The most commonly used finish is Polyester (PE), which provides good durability, weather resistance, and color retention. It is available in a wide range of colors and gloss levels. Another popular option is Polyvinylidene Fluoride (PVDF) finish, known for its excellent resistance to weathering, UV radiation, and chemicals. It maintains color and gloss for extended periods, making it ideal for architectural applications. Polyurethane (PU) finish is preferred for its resistance to abrasion, chemicals, and weathering. It offers a smooth and glossy appearance and is available in various colors. PU finish is commonly used in outdoor applications that require high durability. Epoxy (EP) finish is known for its excellent chemical resistance and adhesion. It is often used in industrial applications where corrosion resistance is crucial. It can be combined with other coatings to enhance its performance. Acrylic (AC) finish provides good weather resistance and color retention. It is commonly used in architectural applications where aesthetics and durability are important. Acrylic finish offers a glossy appearance and a wide range of colors. These examples demonstrate the range of surface finishes available for pre-painted aluminum coils. The choice of finish depends on specific requirements, including desired appearance, durability, and resistance to external factors.

Send your message to us

Alloy Aluminum Coil 3000 Series Cold Rolled Aluminum Coils 1050 1060 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords