All Categories

- - Steel Wire Rod

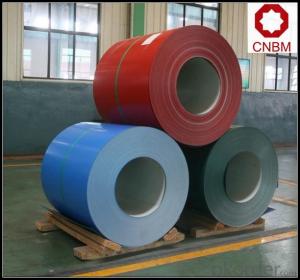

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the common defects that can occur during the manufacturing of aluminum coils?

Some common defects that can occur during the manufacturing of aluminum coils include surface defects such as scratches, dents, or stains, as well as dimensional defects like thickness variations or uneven edges. Other defects can include internal defects like cracks, voids, or inclusions, and mechanical defects such as coil misalignment or improper winding tension. These defects can affect the overall quality and performance of the aluminum coils and may require corrective measures or rejection of the defective coils.

What are the applications of aluminum coils in the marine industry?

Aluminum coils find various applications in the marine industry due to their excellent corrosion resistance and lightweight properties. They are commonly used in the construction of boat hulls, deckhouses, and other structural components. Aluminum coils are also utilized in the manufacturing of marine equipment such as heat exchangers, condensers, and refrigeration units. Their high strength-to-weight ratio makes them ideal for improving fuel efficiency in marine vessels. Additionally, aluminum coils are used in the production of marine-grade aluminum alloys that provide superior performance and durability in harsh marine environments.

How are aluminum coils treated for enhanced thermal conductivity in electronics applications?

Aluminum coils are treated through various methods to enhance their thermal conductivity in electronics applications. One common treatment is the application of a thermal interface material (TIM) between the coil and the electronic component. This TIM helps to bridge any gaps and improve heat transfer between the two surfaces. Additionally, aluminum coils can undergo processes like anodizing or electroplating to further enhance their thermal conductivity. These treatments create a more uniform and efficient heat transfer pathway, ultimately improving the overall thermal performance of the coil in electronics applications.

Wholesale Aluminum Coils from supplier in Afghanistan

Whether you are involved in construction, manufacturing, or any other industry that requires Aluminum Coils, we have the expertise and resources to meet your specific needs. Our sales team is knowledgeable and experienced, ensuring that you receive the right products for your applications.

In addition to sales, we also offer quotations to help you plan your projects effectively. Our team will provide you with detailed and competitive pricing information, allowing you to make informed decisions.

Furthermore, our technical support services are designed to assist you throughout the entire process. From selecting the right Aluminum Coils for your requirements to providing guidance on installation and maintenance, our experts are here to help.

As a subsidiary platform of CNBM, a prestigious Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to provide comprehensive procurement services, ensuring that you receive high-quality Aluminum Coils at competitive prices.

We take pride in our strong presence in the Afghan market. Over the years, we have built a reputation for delivering reliable products and excellent customer service. Our experience in the region is invaluable, and we can offer valuable insights to help you achieve success in your projects.

Whether you have a small-scale requirement or a large-scale project, we are here to cater to your Aluminum Coils needs in Afghanistan. Contact us today to discuss your requirements, receive a quotation, or seek technical support. We look forward to serving you and contributing to your success.

In addition to sales, we also offer quotations to help you plan your projects effectively. Our team will provide you with detailed and competitive pricing information, allowing you to make informed decisions.

Furthermore, our technical support services are designed to assist you throughout the entire process. From selecting the right Aluminum Coils for your requirements to providing guidance on installation and maintenance, our experts are here to help.

As a subsidiary platform of CNBM, a prestigious Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to provide comprehensive procurement services, ensuring that you receive high-quality Aluminum Coils at competitive prices.

We take pride in our strong presence in the Afghan market. Over the years, we have built a reputation for delivering reliable products and excellent customer service. Our experience in the region is invaluable, and we can offer valuable insights to help you achieve success in your projects.

Whether you have a small-scale requirement or a large-scale project, we are here to cater to your Aluminum Coils needs in Afghanistan. Contact us today to discuss your requirements, receive a quotation, or seek technical support. We look forward to serving you and contributing to your success.