Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

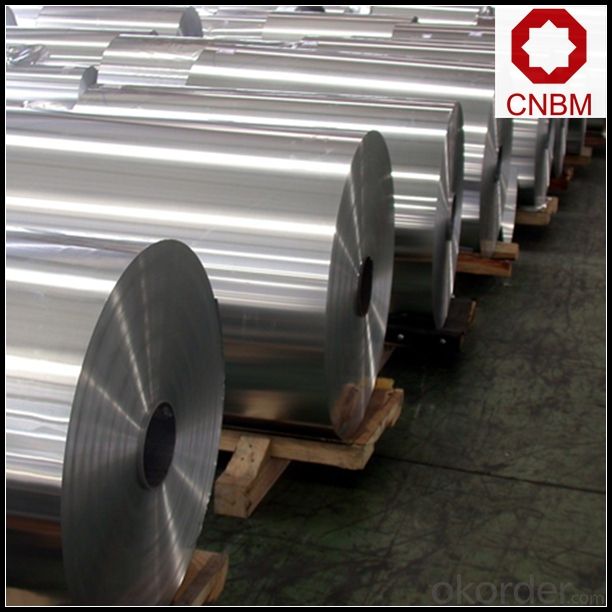

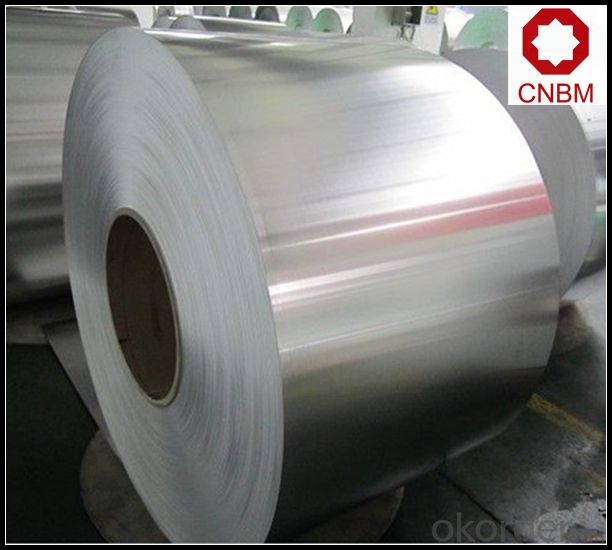

5. Image of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

6. Package and shipping of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: How are aluminum coils protected against UV exposure during storage?

- Aluminum coils are typically protected against UV exposure during storage by being covered with a protective layer or coating. This layer acts as a barrier, preventing direct contact between the coils and UV rays from the sun. Additionally, storing the coils in a shaded area or inside a warehouse can further minimize their exposure to harmful UV radiation.

- Q: Is it safe and effective to use aluminum coils for baking purposes?

- <p>Yes, you can use aluminum coils for baking. Aluminum is a common material used in baking pans and coils due to its excellent heat conduction properties, which allows for even baking. However, it's important to note that some people are concerned about potential health risks associated with aluminum, though these concerns are not universally accepted by the scientific community. Always ensure your aluminum baking coils are food-grade and clean to prevent any contamination.</p>

- Q: Are there any limitations to using aluminum coils?

- Yes, there are several limitations to using aluminum coils. Firstly, aluminum coils are more expensive compared to other coil materials such as copper. This can be a limiting factor for individuals or businesses with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means that they are less efficient at transferring heat, which can result in decreased performance in some applications. Additionally, aluminum is more susceptible to corrosion and oxidation compared to other materials. This can be a limitation in environments that are highly corrosive, such as coastal areas or industrial settings. Furthermore, aluminum coils are generally not suitable for high-pressure applications. They are more prone to leaks or failures under high pressure, which can limit their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are not as malleable as copper coils, making them more difficult to work with during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, while aluminum coils have their advantages such as being lightweight and environmentally friendly, they also have limitations that need to be considered based on the specific application and requirements.

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum is a highly efficient and effective material for heat transfer due to its high thermal conductivity. It can quickly transfer heat from one medium to another, making it ideal for heat exchangers where efficient heat transfer is required. Additionally, aluminum coils are lightweight, corrosion-resistant, and have excellent durability, making them a popular choice for various applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can withstand harsh environments and prevent the formation of rust or corrosion, prolonging the lifespan of the heat exchanger. Moreover, aluminum coils are easily moldable and can be formed into various shapes, allowing for flexibility in design and construction of heat exchangers. This versatility makes them suitable for a wide range of applications, including HVAC systems, refrigeration units, and automotive cooling systems. In summary, aluminum coils are well-suited for heat exchangers due to their high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility. These properties make aluminum coils an excellent choice for efficient heat transfer in various industries.

- Q: This question asks for a comparison of the benefits and drawbacks associated with using aluminum coil.

- <p>Aluminum coil offers several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent thermal and electrical conductivity. It is also cost-effective and easy to form, making it ideal for various applications like construction, automotive, and electrical industries. However, it has some disadvantages, including lower strength compared to steel, potential for galvanic corrosion when in contact with dissimilar metals, and a higher likelihood of denting or denting. Additionally, aluminum's recycling process can be energy-intensive, which may impact its environmental sustainability.</p>

- Q: What are the various applications and purposes of aluminum coil in different industries?

- <p>Aluminum coil is widely used in numerous applications due to its lightweight, corrosion resistance, and high strength. It is commonly used in construction for roofing and siding, in the automotive industry for body panels and heat exchangers, and in the packaging industry for food and beverage cans. Aluminum coil is also utilized in electrical applications such as transformers and wiring, and in the manufacturing of everyday items like foil and cookware. Its versatility makes it a popular material in various industries.</p>

- Q: Aluminum roll, which companies are used?

- Too many things that you can see every day, with all the things that are made of aluminum, and the companies that make these aluminum products are useful, so it's unclear!

- Q: Are aluminum coils recyclable?

- Yes, aluminum coils are recyclable. Aluminum is one of the most recyclable materials, and it can be recycled indefinitely without losing its quality. The recycling process of aluminum coils involves melting them down to form new coils or other aluminum products. This not only reduces the amount of waste in landfills but also saves energy and resources required to produce new aluminum from raw materials. Recycling aluminum coils is an environmentally friendly choice that helps conserve natural resources and reduce greenhouse gas emissions.

- Q: Are there any limitations on the length of aluminum coils?

- There are indeed limitations on the length of aluminum coils. While aluminum coils can be produced in various lengths, they are typically limited by practical factors such as transportation, handling, and manufacturing capabilities. Transportation is one of the major limitations as longer coils may become difficult to move efficiently. The size and weight of longer coils can pose challenges for loading and unloading, as well as shipping and logistics. Additionally, longer coils may require specialized equipment for transportation, which can add to the overall cost and complexity. Handling is another limitation, as longer coils can be harder to maneuver and manipulate during various stages of production. They may require larger and more robust machinery to process, which may not be available or feasible in all manufacturing facilities. Furthermore, manufacturing capabilities can impose restrictions on the length of aluminum coils. The equipment used to produce coils may have certain limitations in terms of size and capacity. Coil processing lines and machinery may have maximum lengths they can handle, and exceeding these limits may not be possible or economically viable. In summary, while there is no specific universal limit on the length of aluminum coils, logistical, handling, and manufacturing constraints can impose practical limitations. The specific length of aluminum coils would depend on various factors including transportation, handling capabilities, and the manufacturing processes involved.

Send your message to us

Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords