Aluminum Coil Spool - Cold Rolling Gutter Aluminum Coil 3003 3004 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

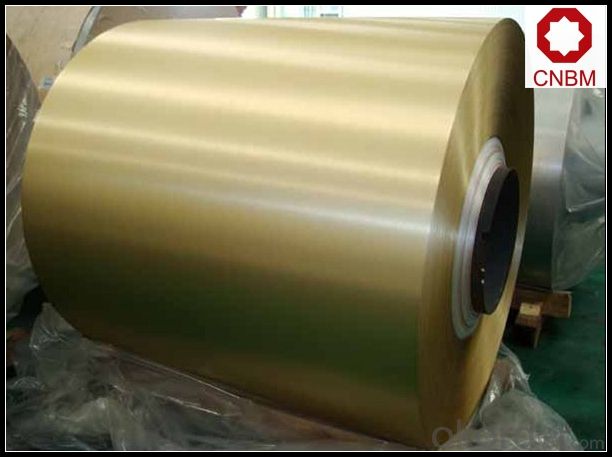

13) Surface: Bright

14)Origin: China

2. Application of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

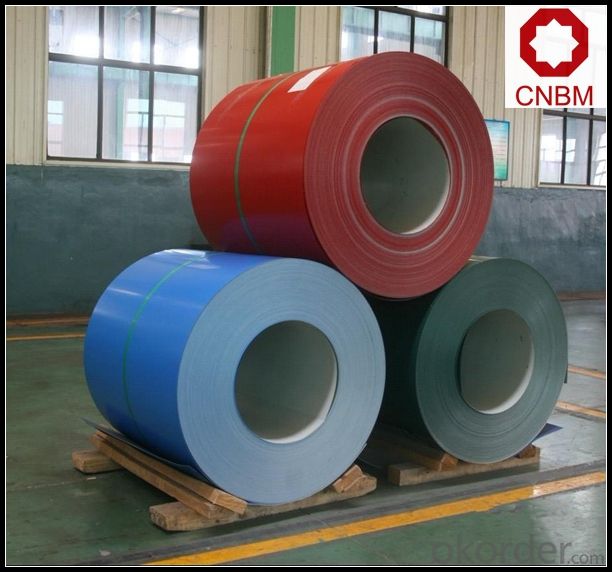

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

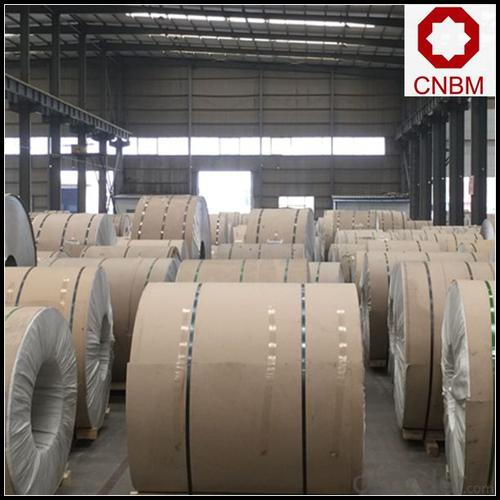

5. Image of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

6. Package and shipping of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Guangdong where there are professional to do around the paper corner, is packing steel coil, aluminium coil that protect the edge of the both ends of the cylinder. Just the kind of picture.

- Guangdong Province, professional Foshan recommended edgeboard around Foshan Ansheng packaging. They are very professional in their circle, L shaped, and curved corners.

- Q: This question asks if aluminum coils are susceptible to rusting.

- <p>Aluminum coil does not rust in the traditional sense. Instead, it forms a thin, protective layer of aluminum oxide when exposed to air, which prevents further corrosion. This oxide layer is different from rust, which is iron oxide. While aluminum can tarnish or corrode under certain conditions, such as exposure to certain chemicals or in extreme environments, it does not rust like iron or steel. Proper storage and handling can help maintain the integrity of aluminum coils and prevent unwanted reactions.</p>

- Q: Is it possible to recycle aluminum coils without any loss in their quality?

- <p>Yes, aluminum coils can be recycled without damaging their quality. Aluminum is one of the most recycled materials due to its ability to be recycled indefinitely without any loss in quality. The recycling process involves melting the aluminum, which can then be reshaped into new coils or other products. This process is energy-efficient and environmentally friendly, as it requires significantly less energy than producing aluminum from raw materials. Recycled aluminum maintains the same strength, durability, and appearance as new aluminum, making it a sustainable choice for various applications.</p>

- Q: I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- It depends on how old the paint is. If your panel was painted before the 1970's, then pretty much any chemical paint stripper will work. After the 70's, they started using epoxy based primers and paints and those are more resistant to chemical strippers. In any case, wear rubber gloves and breathing protection while using chemical paint strippers. They can burn your skin and create toxic fumes when in use.

- Q: Are there any specific guidelines for the handling of aluminum coils?

- Yes, there are specific guidelines for the handling of aluminum coils. These guidelines typically include proper lifting techniques, the use of appropriate equipment such as cranes or forklifts, and ensuring that the coils are stored in a clean and dry environment to prevent corrosion. It is also important to handle the coils gently to avoid any damage or deformation.

- Q: How to use aluminum sheet to roll a 12m-long aluminum coil with a diameter of 184cm?

- According to project experience, first you should check the specification of the aluminum sheet and then design crafts such as connection method, installation and transportation according to equipment.

- Q: How are aluminum coils made?

- Continuous casting and rolling is the method utilized for the production of aluminum coils. The process commences by melting aluminum ingots or scrap in a furnace. After reaching the desired temperature, the molten aluminum is transferred to a holding furnace. Subsequently, the molten aluminum is continuously cast into a solidified strip, which is then passed through a series of rolling mills. The rolling mills exert pressure on the aluminum strip, reducing its thickness while increasing its length. This procedure is repeated multiple times until the desired thickness and width are attained. Simultaneously, the aluminum strip is cooled and lubricated during the rolling process to prevent adherence to the rollers and enhance the surface finish. Once the rolling is complete, the aluminum strip is coiled to form a continuous sheet of aluminum coil. To ensure stability during transportation and storage, the coils are typically wound tightly, minimizing any air gaps. At this stage, the coils can undergo further processes such as annealing. This involves heating the coils and gradually cooling them to enhance their mechanical properties, making them more suitable for specific applications. In summary, the production of aluminum coils comprises a combination of melting, casting, rolling, and coiling procedures. The ultimate goal is to generate top-quality coils with the desired dimensions and properties.

- Q: How are aluminum coils transported and packaged?

- Aluminum coils are typically transported and packaged using wooden crates or pallets. The coils are securely strapped or bundled together to prevent movement during transit. They are then loaded onto trucks or shipping containers for transportation, ensuring they are well-protected to avoid any damage or deformation.

- Q: What are the common maintenance practices for aluminum coils?

- Some common maintenance practices for aluminum coils include regular cleaning to remove dirt and debris, checking for any signs of corrosion or damage, ensuring proper airflow and ventilation around the coils, and regular inspections to identify and address any potential issues. Additionally, it is important to follow manufacturer guidelines and recommendations for maintenance and to schedule professional servicing when necessary.

- Q: Can aluminum coils be used in automotive heat shields?

- Indeed, automotive heat shields can utilize aluminum coils. Thanks to its exceptional resistance to heat and lightweight characteristics, aluminum is extensively employed in heat shield production. By shaping and forming aluminum coils according to the desired design, automotive applications can benefit from straightforward installation and customization. Moreover, the high thermal conductivity of aluminum aids in efficiently dissipating heat, rendering it an optimal option for vehicle heat shields.

Send your message to us

Aluminum Coil Spool - Cold Rolling Gutter Aluminum Coil 3003 3004 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords