Camo Aluminum Sheets - Industrial 0.2 0.3mm 3003 3004 3105 Cold Rolling Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

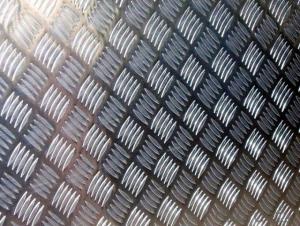

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

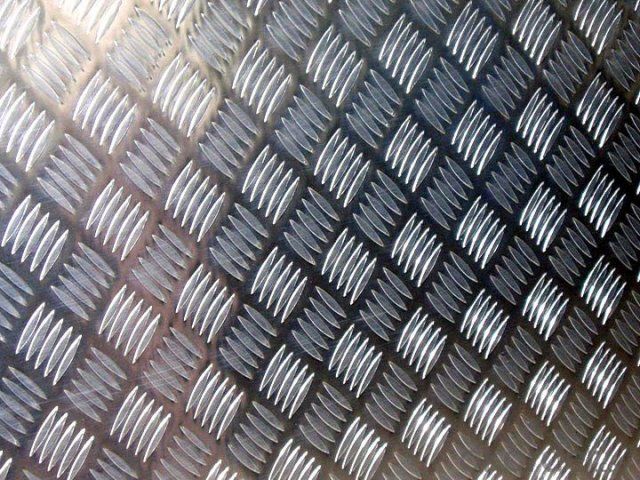

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on the specific application and requirements. Aluminum sheets are available in a wide range of thicknesses, typically ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even thicker. The thickness is usually measured in gauge, with higher gauge numbers indicating thinner sheets. It is important to consider the intended use and desired properties, such as strength, flexibility, or weight, when selecting the appropriate thickness for an aluminum sheet.

- Q: Can aluminum sheet be used for insulation?

- Aluminum sheet can be used for insulation, but it is not as effective as other insulation materials, such as fiberglass or foam. Aluminum has a low thermal conductivity, meaning it is a poor conductor of heat. However, it does not have good insulating properties on its own because it does not provide much resistance to heat flow. In order to use aluminum sheet for insulation, it is commonly combined with other insulating materials to enhance its effectiveness. For example, aluminum foil is often used as a radiant barrier in buildings to reflect heat and reduce the amount of heat transferred through walls and roofs. Overall, while aluminum sheet can contribute to insulation, it is usually used in conjunction with other materials to provide better thermal insulation.

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can indeed be an alternative to plastic in certain applications. Aluminum is a highly versatile and sustainable material that offers several advantages over plastic, such as being more durable, resistant to UV rays, and having a longer lifespan. Additionally, aluminum is recyclable and can be reused indefinitely, making it a more environmentally friendly choice. However, the suitability of aluminum sheets as an alternative to plastic would depend on the specific application and requirements.

- Q: What are the different machining options for aluminum sheets?

- There are several different machining options available for aluminum sheets, depending on the desired outcome and the specific requirements of the project. Some of the most common machining options for aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various methods such as shearing, sawing, or laser cutting. Shearing involves using a shearing machine to apply a high force to the sheet, resulting in a clean and straight cut. Sawing, on the other hand, utilizes a saw blade to cut through the aluminum sheet. Laser cutting uses a high-powered laser beam to melt or vaporize the aluminum, resulting in a precise and accurate cut. 2. Drilling: Drilling is a common machining option used to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet, creating a hole with the desired diameter. Different drill bits can be used to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create complex shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in a precise and accurate finish. Milling can be done using various types of milling machines, such as vertical milling machines or CNC milling machines, depending on the complexity of the project. 4. Turning: Turning is another machining option used for aluminum sheets, especially when creating cylindrical or conical shapes. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet to the desired dimensions. Turning can be done on manual lathes or CNC turning machines, depending on the level of precision required. 5. Bending: Bending is a common machining option used to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press, or it can be done using hydraulic or CNC press brakes for more precise and consistent results. These are just a few of the different machining options available for aluminum sheets. The choice of machining method will depend on factors such as the desired outcome, the complexity of the project, and the resources available. It is important to select the most suitable machining option to achieve the desired results efficiently and effectively.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: How are aluminum sheets cleaned and maintained?

- Aluminum sheets can be cleaned and maintained by following a few simple steps. Firstly, they should be wiped down regularly with a soft cloth or sponge and mild detergent to remove any dirt or grime. Avoid using abrasive materials or cleaners that contain bleach or ammonia, as they can damage the surface. After cleaning, it is recommended to rinse the sheets thoroughly with clean water and dry them with a soft cloth to prevent water spots. To maintain their shine, applying a coat of aluminum polish or a mixture of vinegar and water can help remove any oxidation or dullness. Additionally, it is important to protect aluminum sheets from harsh elements by storing them in a dry and clean environment and avoiding contact with corrosive substances.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: How does the thickness of aluminum sheet affect its strength?

- The thickness of an aluminum sheet directly affects its strength. In general, a thicker sheet of aluminum will be stronger than a thinner one. This is because the thickness of the sheet determines the amount of material present, which in turn affects the sheet's ability to withstand external forces or loads. The strength of a material is typically measured by its ability to resist deformation or failure under stress. Thicker aluminum sheets have a greater volume of material, which means there are more atoms and bonds available to withstand forces. This results in a higher resistance to deformation or failure, making the sheet stronger. Additionally, a thicker aluminum sheet also has a higher load-bearing capacity. This means it can support heavier loads or withstand higher pressures without deforming or failing. The increased thickness provides more material to distribute the load, reducing the stress on individual atoms and bonds within the sheet. However, it is important to note that there is a limit to the thickness at which the strength of the aluminum sheet plateaus. Beyond a certain point, further increasing the thickness may not significantly improve its strength. This is because the material properties of aluminum, such as its crystal structure and grain boundaries, also play a role in determining its strength. In conclusion, the thickness of an aluminum sheet directly affects its strength. Thicker sheets have more material, enabling them to resist deformation or failure under stress more effectively. This increased thickness also allows them to support heavier loads or withstand higher pressures. However, there is a limit to the thickness at which the strength plateaus, as other material properties come into play.

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Yes, 101 aluminum sheets are suitable for radiator manufacturing. 101 aluminum is a commercially pure aluminum alloy that offers excellent thermal conductivity, making it ideal for use in radiators. It is also highly corrosion-resistant, which is crucial for radiator applications where exposure to water and other fluids is common. Additionally, 101 aluminum sheets are lightweight and easy to work with, allowing for efficient radiator production processes. Overall, 101 aluminum sheets provide the necessary properties and characteristics required for radiator manufacturing.

- Q: What are the different types of finishes available for painted aluminum sheets?

- Painted aluminum sheets come in various finishes, each with its own distinct features and advantages. 1. For a non-reflective and dull appearance, the matte finish is ideal. This option is commonly utilized in architectural elements and interior design for a low-gloss look. 2. If you prefer a shiny and reflective surface, the gloss finish is the way to go. This finish is often chosen for automotive parts and decorative panels, giving them a sleek and polished appearance. 3. To add texture and patterns to the painted aluminum sheet, opt for a textured finish. This type of finish is commonly used for decorative purposes, enhancing visual appeal and providing a unique tactile experience. 4. Achieve a metallic appearance resembling stainless steel or bronze with a metallic finish. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder coating is a popular finishing method where a dry powder is applied to the painted aluminum sheet and cured under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Protect and enhance the durability of a painted aluminum sheet with a clear coat finish. This transparent finish provides an extra layer of protection against UV rays, moisture, and other environmental factors. Consider the intended use and desired aesthetic when selecting a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

Send your message to us

Camo Aluminum Sheets - Industrial 0.2 0.3mm 3003 3004 3105 Cold Rolling Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords