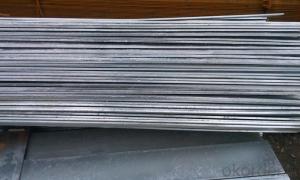

Cold drawn square steel; high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

stainless steel square bar flat steel bar

Diameter:2-500mm

Length:Customized

Quality: High quality stainless steel bar

stainless steel square bar flat steel bar

Stainless Steel bar

Diameter:2-160mm

Length: Customized

Surface | bright,black |

Technique | Hot Rolled/Cold Drawn/Peeled |

1.Round bar 1Hot rolled black bar: (5~400x6000mm or according to your requirement. 2Acid round bar: (5~400)x6000mm or according to your requirement. 3Cold drawn bright bar: (1~20x6000mm or according to your requirement. 4)Polishing round bar: (5-400)x6000mm or according to your requests. | |

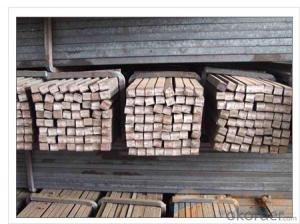

2. Square bar 1)Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests. 2)Acid square bar: (5*5-400*400)x6000mm or according to your requests. 3)Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests 4)Polishing square bar: (5*5-400*400)x6000mm or according to your requests | |

Diameter± | H9 tolerance can reach the industry standard |

Quality | Our production equipment 24 hours of continuous temperature work, to ensure the unity of the product roundness, elongation, tensile strength and yield strength. Welcome customers to our company to detect the products before shipment. For the customers who are not inconvenient, quality assurance can be laid down in the contract, we will take charge of the returning and shipping fee if there is any problems of the product quality, so it will dismiss any of your worry about our products. |

Package | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

Delivery time | 7-20days, according to the quantity |

Productivity | 10000 tons/month |

Stainless steel round bars:

Grade :200 series 300series 400series. (Standard: ASTM JIS DIN & BS)

Diameters: 4mm-300mm

Surface : white acid , annealed, black(hot rolled) , bright and following customers request.

Length: 6M(standard) or random

Packing: standard export packing or following customer’s demand.

- Q: How do you use a steel square to create finger joints?

- To use a steel square to create finger joints, you would first mark the width and length of the fingers on the edge of the board using the square. Then, you would use the square to mark the depth of each finger by aligning it with the width marks. Once marked, you can use a saw to cut along the marked lines, creating the fingers. The steel square helps ensure accurate measurements and straight lines, resulting in well-fitted finger joints.

- Q: What is the difference between a framing square and a try square?

- A framing square and a try square are both types of square tools used in woodworking and construction, but they have some key differences in their design and purpose. A framing square, also known as a carpenter's square or steel square, is a larger and more versatile tool. It typically has a longer blade, usually around 24 inches, and a shorter tongue or handle, which is usually around 16 inches. The blade and tongue are joined at a 90-degree angle, forming an L-shape. This design allows the framing square to be used for a variety of tasks, such as laying out and marking right angles, checking the squareness of structures, measuring angles, and making complex calculations in carpentry and framing work. On the other hand, a try square is a smaller and more compact tool. It consists of a short blade, usually around 6 to 12 inches, and a shorter handle, typically around 3 to 6 inches. The blade and handle are also joined at a 90-degree angle, forming an L-shape similar to the framing square. However, the try square is primarily used for checking and marking right angles, ensuring the accuracy and squareness of joints, and making precise measurements in woodworking projects, such as marking and cutting 90-degree angles on boards or checking the squareness of edges and corners. In summary, the main difference between a framing square and a try square lies in their size, versatility, and intended use. A framing square is larger, more versatile, and used for a wide range of tasks in carpentry and construction, while a try square is smaller, more compact, and primarily used for checking and marking right angles in woodworking projects.

- Q: How do you use a steel square to determine the slope of a ramp?

- To use a steel square to determine the slope of a ramp, you will need to follow the following steps: 1. Place the steel square at the bottom of the ramp, ensuring that the long edge of the square is in contact with the surface of the ramp. 2. Hold the steel square in place and align the level vial, which is located on the square, so that it is parallel with the long edge of the square. 3. Slowly lift the other end of the steel square until the level vial indicates that it is perfectly level. 4. Once the steel square is level, measure the height of the lifted end of the square from the ground. This can be done by using a measuring tape or ruler. 5. Measure the horizontal distance from the bottom of the ramp to the lifted end of the square. Again, use a measuring tape or ruler for this step. 6. Now, to determine the slope of the ramp, divide the height measurement by the horizontal distance measurement. This will give you the slope ratio or gradient of the ramp. 7. If you prefer a percentage slope, multiply the slope ratio by 100. This will give you the percentage of the slope. For example, if the height measurement is 2 feet and the horizontal distance measurement is 10 feet, the slope ratio would be 2/10 or 0.2. To convert it to a percentage, multiply 0.2 by 100, resulting in a 20% slope. By following these steps, you can accurately determine the slope of a ramp using a steel square.

- Q: What are some common measurements that can be taken with a steel square in HVAC work?

- In HVAC work, a steel square is a versatile tool that can be used for various measurements. Some common measurements that can be taken with a steel square include: 1. Right angles: The steel square is primarily used to ensure the accuracy of right angles. It can be used to check if walls, ductwork, or equipment are perfectly perpendicular or if corners are square. This is crucial for proper alignment and installation in HVAC systems. 2. Angles and slopes: A steel square can be used to measure and mark angles and slopes. It helps in determining the correct pitch for drain lines, ensuring proper water flow and preventing standing water or condensation issues. 3. Parallel lines: The steel square can be used to establish parallel lines, ensuring proper alignment of pipes, ducts, or other HVAC components. It helps in maintaining consistency and preventing misalignments that could impact system performance. 4. Measurements: The steel square typically has markings on its blade, which can be used for measuring length, width, or height of various HVAC components. It provides quick and accurate measurements for precise installations. 5. Layouts and templates: Steel squares are often used for creating layouts and templates for HVAC installations. They can be used to mark cutting lines, angles, or notches on materials like sheet metal, ensuring accurate and efficient fabrication. Overall, a steel square is an essential tool in HVAC work, providing reliable measurements for ensuring proper alignment, angles, and dimensions. It helps in achieving efficient and accurate installations, ultimately improving the performance and longevity of HVAC systems.

- Q: How do you use a steel square to determine angles for window trim?

- To use a steel square to determine angles for window trim, you can follow these steps: 1. Start by measuring the width and height of the window opening using a tape measure. Take note of these measurements. 2. Next, place the steel square against the corner of the window opening, aligning one edge of the square with the side of the window frame. 3. Take a pencil or marker and mark along the edge of the square where it intersects with the top and bottom of the window frame. This creates two lines on the edge of the square. 4. Now, remove the steel square from the window frame and align the marked lines on the square with the corresponding sides on the square's ruler. 5. Look for the angle measurement on the ruler where the other edge of the square intersects. This will give you the angle of the window trim that needs to be cut. 6. Transfer this angle measurement onto the window trim material by using a protractor or an adjustable angle tool to ensure accuracy. Mark the angle on the trim material. 7. Use a miter saw or a handsaw to cut the window trim along the marked angle. Make sure to cut precisely along the marked line. 8. Test the cut trim piece against the window opening to ensure a proper fit. If needed, make any necessary adjustments to the angle by recutting the trim. By using a steel square, you can accurately determine the angles for window trim, allowing for a precise fit and a professional finish.

- Q: What are some alternative tools to a steel square?

- There are various options available as alternatives to a steel square for different tasks. The following are some of these alternatives: 1. Framing Square: In carpentry and framing projects, a larger version of a steel square called a framing square is commonly used. It consists of two arms, one longer and one shorter, forming a right angle. The longer arm usually has measurements and markings for easy angle and length calculations. 2. Combination Square: For measuring, marking, and checking right angles in woodworking and metalworking projects, a versatile tool called a combination square is used. It combines a ruler, a square, and a level. 3. Speed Square: In roofing and carpentry projects, a triangular-shaped tool known as a speed square, rafter square, or triangle square is commonly used. It serves multiple purposes, including measuring and marking angles, determining roof pitches, and acting as a saw guide. 4. Sliding T-Bevel: To transfer and measure angles, a tool called a sliding T-bevel is used. It consists of a handle and a blade that can be adjusted to any desired angle and locked in place. Woodworking and metalworking projects often employ this tool for marking and replicating angles. 5. Angle Finder: An angle finder is a tool used for accurate measurement and transfer of angles. It typically comprises two arms with pivoting joints that allow for easy adjustment and locking. Carpentry, metalworking, and construction projects commonly rely on angle finders. 6. Digital Angle Finder: For working with complex angles or when a high level of accuracy is required, a more advanced version of an angle finder called a digital angle finder is used. It usually has a digital display that provides precise angle measurements. Depending on the specific task, these alternative tools can serve as excellent replacements for a steel square. They offer unique functionalities and features that cater to different needs and preferences.

- Q: How do you use a steel square for marking stair handrail height?

- To use a steel square for marking stair handrail height, first, position the square against the vertical post or newel at the base of the stairs. Ensure that the square's short leg is aligned with the top of the post, while the long leg extends upward, representing the desired handrail height. Use a pencil to mark along the long leg of the square onto the post. Repeat this process on the opposite post to ensure accuracy and consistency. Finally, connect the marks with a straight edge or level, providing a clear guideline for installing the handrail at the appropriate height.

- Q: How do you use a steel square to determine the angle of a compound fluting cut?

- In order to determine the angle of a compound fluting cut using a steel square, the following steps should be followed: 1. Begin by positioning the steel square on the workpiece, ensuring that its long side runs parallel to the edge of the material to be fluted. 2. Align one of the edges of the steel square with the material's edge, ensuring a secure hold. 3. Proceed to draw a line along the other edge of the steel square onto the material. This line will serve as a reference for the fluting cut angle. 4. Utilize a protractor or a bevel gauge to accurately measure the angle between the reference line and the desired direction of the fluting cut. 5. Once the angle has been determined, transfer it to your chosen cutting tool or machine. This can include a router, table saw, or any other appropriate tool capable of executing the fluting cut. 6. Adjust your cutting tool or machine to match the measured angle. This might involve modifying the table or fence on a table saw, or changing the angle of the router bit. 7. Before initiating the cut, double-check your setup to ensure the correct alignment of the tool or machine. 8. Finally, carefully guide the material through the cutting tool or machine, following the determined angle, to make the compound fluting cut. Always prioritize safety when working with cutting tools or machines. Adhere to the manufacturer's instructions and wear appropriate protective gear to prevent accidents and injuries.

- Q: The steel structure material can do?

- The steel can be used as structural materials to use, but not commonly used, are generally only used in the special requirements of the situation

- Q: How do you use a steel square to measure and mark 33.75-degree angles?

- To measure and mark a 33.75-degree angle using a steel square, begin by placing the square's 90-degree corner against the edge of the material you want to mark. Then, align one of the square's legs with the same edge. Next, rotate the square until the other leg aligns with the desired angle, which in this case is 33.75 degrees. Finally, use a pencil or a scribe to mark the intersection of the square's leg with the material, indicating the 33.75-degree angle.

Send your message to us

Cold drawn square steel; high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords