CMAX QTK40 Self Erection Tower Crane ,Inner Tower Expansion

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTK40 SELF ERECTION TOWER CRANE

1.1 Brief introduction

The QTK40 model self erection tower crane is developed by our company on basis of years of experiences in production and new technical innovation.This tower crane is whole consignment & fast set-up vertical and level transport machinery. Mainly apply to 7~10 storey civil buildings. This machine also could used in factory, goods yard, station, ports to move products, as well as to be a mobile hoisting machine.

1.2 Features

The famous feature of this kind tower crane could realize fast-installation and whole consignment transportation. After whole enfolding of tower crane, two workers could transport tower crane by one truck crane (8ton), and the installation could be finished within 40 minutes.

Other features:

(1) Inner tower expansion in suit place, it could auto-lock and release

(2) lifting beam could auto-unfold or fold when towers stretch and unfold

(3) (Tower stretch and unfold, beam unfold, counter weight load ,which all could do range form 0~360°

(4) Adopt drum, whole steel wire rope pulley system, to realize lifting& installation set-up work

(5) Have two kinds interchange device: track and fixed supporting lug, to adjust different uses

(6) The angle of altitude of lifting beam is 15, then could increase the height of lift, but its Max lift weight is 1100kg .

(7) Lifting mechanism, trolleying mechanism and traveling mechanism adopt frequency & gear changable to control speed.

(8) Slewing gear adopt electric resistance control mode, smooth starting, with good positioning performance

1.3 Main technical data

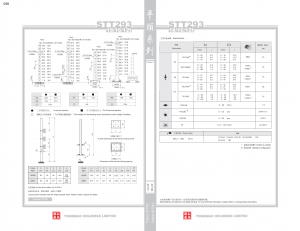

1.3.1 Main technical data

Lifting moment | kN·m | 400 |

Rated lift weight(level beam/ overhead beam 15°) | t | 1.1~4.0(1.1) |

Work range (level beam/ overhead beam 15°) | m | 4~36(4~34.5) |

Lift height(level beam/overhead beam 15°) | m | 23.5(32.5) |

Track moment x axle moment | m | 3.8×3.8 |

Work wind scale | level | 6 |

Self weight | t | 14.63 |

Counterweight | t | 22.88 |

Radius of tail gyration | m | 3.2 |

Cable drum driving distance | m | 20(left and right) |

Rail type | kg/m | 43 |

Equipment total power (380V/50Hz/3) | kW | 25.9 |

1.3.2 Speed & motor power

Mechanism name | Unit | Work speed | Power (KW) | |

Lifting mechanism | (m/min) | α=2 | α=4 | 11KW |

0~29 | 0~14.5 | |||

Jib lubbing mechanism | (m/min) | 9.0 | 4KW | |

Trolley mechanism | (m/min) | 20/30 | 2.2/1.5KW | |

Traveling mechanism | (m/min) | 0~24 | 2×1.5KW | |

slewing mechanism | (r/min) | 0~0.65 | 55 N·m | |

1.3.3 Lift performance data

Four rates:

R(m) | 4-11 | 12 | 14 | 16 | 18 | 20 | 22 |

kg | 4000 | 3654 | 3106 | 2696 | 2377 | 2122 | 1913 |

R(m) | 24 | 26 | 28 | 30 | 32 | 34 | 36 |

kg | 1739 | 1591 | 1465 | 1356 | 1260 | 1175 | 1100 |

Two rates:

R(m) | 4-21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 |

kg | 2000 | 1913 | 1822 | 1739 | 1622 | 1591 | 1526 | 1465 |

R(m) | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 |

kg | 1408 | 1356 | 1306 | 1260 | 1216 | 1175 | 1137 | 1100 |

Beam structure 15 °angle of altitude property list(Two rates)

Work range R(m) | Max load Q(kg) | Max lifting height H(m) |

3.5~34.5 | 1100 | 32.5 |

1.4 Main transport parameter

1.4.1 Transport on railroad

Ready machine weight P is about 14.63 tons, and the distance from center of gravity to the slewing center is about 0.6 m.

Attention: in order to make the railway transport is not overrun, the following components must be removed:

(1) the dragged mechanism for highway transport;

(2) Pack up the traveling mechanism and fixed brace fold;

(3) others please refer to the packing requirements and shipping list.

1.4.2 Highway transport

Tire load table

Bridge load(t) | Tire | ||

Model | Qty | ||

front | 5380 | 9.00R20 | 2 |

back | 9250 | 9.00R20 | 4 |

1.5 Pictures

FAQ of CMAX QTK40 Self Erection Tower Crane ,Inner Tower Expansion

What's other improtant advantages ?

1)Fast, simple and safe erection of small, light individual modules.

2)Excellent choice for narrow sites in the city as there is no need to pre-assemble the whole jib on the ground.

3)Stable funcion of Frequency Inverters and other electrical control systems for 3 main mechanism, and easy and convenient self repair and maintenance for the clients.

4)Twice ball blasting and twice painting for steel structure surface of CJ tower cranes, the hot-dip galvanizing process is used on the handrails, and the time limit of the galvanized quality assurance is 50 years.

5)Good at endurance, adapting to atrocious weather like higher of lower temperature, acid rain and typhoon.

- Q: How to choose tower crane in engineering, such as arm length and lifting weight?

- How to choose tower crane in engineering:1, according to the general layout plan on the mechanical layout requirements to determine. The tower crane's arm length should be swept to the required area, otherwise the worker's formwork and materials can not be transported vertically. (tower crane is the main tool to solve vertical transportation, and auxiliary tools are derricks and double cage elevators)2. After a project has been obtained, it is important to design the layout plan of the field machinery at first. It determines the position of the tower crane and uses several tower cranes, etc. it also conforms to the requirements of economic rationality.3, we should take into account the location of the tower crane, but also take into account the length of the tower crane, but also to meet the requirements of the site construction schedule.

- Q: Many schools I visited claim to teach styles like white crane and even Okinawa/Japanese Karate has come from white crane styles, however I seldom see techniques, kata, forms, or drills that encompass crane concepts of even crane movements. Why is that? At some traditional schools kung-fu/karate it is easy to see the animal influence but at others there is none. Does this also indicate a lack of understanding or incomplete training. What do you think.

- Similarly, karate systems like Goju-Ryu and Uechi-Ryu clearly have some of the same movement patterns. Edit: To Internalize proper form and function often calls for a tangible example, like an animal Disagree. People aren't shaped like birds. We've figured out how to do TONS of stuff with our bodies (hit baseballs, high jump, breaststroke, pole dancing, etc) without looking to animal sources. Fighting is no different. Humans fight like humans. If we should look to any animals, it should be other primates, but again, we lack some of the attributes they have. Never seen a gorilla throw a jab, but it's pretty much been acknowledged by numerous sources as the most important punch in fighting, for example.

- Q: how do you think the auther of the legend of the sleepy hollow developed the charactor ichabod crane?

- I hope this will help you.

- Q: i probably sound like an idiot asking this question :Pis it electricity? fossil fuel burning involved? pulleys? how does the pulley work? any human power involved? specifically, how is it stupid to lift a chair that can be lifted by a person, with a crane?

- Most cranes are diesel engine powered hydraulics and hydraulic motor. So that would be fossil fuel. Some cranes use pulleys to magnify the total lifting capacity. A pulley magnifies work by exchanging distance for lifting power. For example, to lift a 10 ton weight 20 feet in the air, if you put four pulleys in there so that 80 feet of cable would have to be pulled up , then it would only take 1/4 the amount of power to lift that 10 tons (2.5 ton lifting force would lift it) Look at any links or wikipedia for how compound pulleys work.

- Q: It`s like a big box filled with toys and u insert a coin and then u have 2 handle the small crane to pick up a toy...

- There is one version called the Grab-O-Matic, and it is on sale at www.LeapsandBounds for $20.95, usually $34.95.

- Q: Can anyone help me interpret the poem Fear by Hart Crane? or North Labrador?

- Analysing Poetry Close reading may seem like a foreign and unfamiliar approach to analyzing a piece of text. However, it can often yield insights that will help you to create a unique paper developed from your own interpretation of the text. To analyze the work effectively, it is useful to concentrate on specific components of literature used to build and reveal the themes in the work. This process will help you explain how a passage relates to central themes in the text allowing you to reach an intelligent and creative thesis for a literary analysis. First, choose a passage (or a series of passages) that intrigues you.

- Q: I'm talking about one of the ones where the cabin and the worker is high up in the air. You cant exactly remove a part of the bottom of the cranes structure because it would fall on top of you but you cant remove the cabin because its so high up and what can get up that high to remove it except another crane BUT how did that get built ?Thank you.

- A tower crane is usually assembled by a telescopic crane of smaller lifting capacity but greater height and in the case of tower cranes that have risen while constructing very tall skyscrapers, a smaller crane (or derrick) will sometimes be lifted to the roof of the completed tower to dismantle the tower crane afterwards. A self-assembling tower crane lifts itself off the ground using jacks, allowing the next section of the tower to be inserted at ground level.

- Q: They;re ENORMOUS!!! Do they take them apart or something?

- They are broken down into smaller unit pieces and are transported by truck or rail.

- Q: Two Cranes have been sitting on nest for about 50 days. Will these 2 eggs hatch. They will not leave. It is their 3 Clutch. The first one resulted in a baby colt, but it got hit by car. The second never hatched.

- What species of crane? Sandhill cranes have an incubation time of around 30 days, do you know the exact day of egg laying? Are you sure they haven't hatched and they are sitting on chicks? If you are getting close enough to the nest to see eggs or chicks, you might be too close and could be interfering with their natural behavior, unless they are captive or you are using a blind. You mentioned their chick being hit by a car, so if they are nesting that close to people, they may be nervous and are flushed from the nest too often to keep the eggs the right temperature. It's hard to say without more information. Edit: Extra cold weather can damage the eggs. It does seem like they've lost this clutch-50 days is long past when they should have hatched. They may be trying to incubate them anyway, I haven't worked directly with sandhills, but other birds that I've conducted nest monitoring studies on have sometimes sat on nests a while past when the eggs should have hatched. Hopefully this is actually their fourth clutch and you missed the removal of the third clutch. Good luck!

- Q: A crew built this huge crane to build an office building next to my house.... There is a huge flag hanging from the top of it.... Why does the construction company do this???

- probably becasue they are proud of their country

Send your message to us

CMAX QTK40 Self Erection Tower Crane ,Inner Tower Expansion

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords