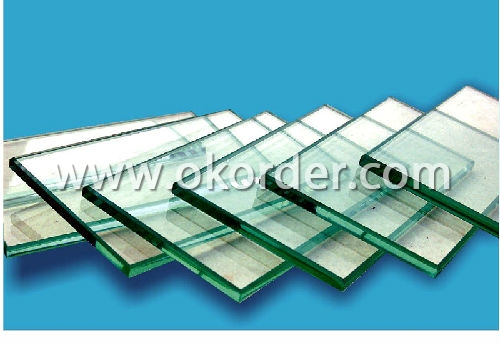

Clear Low-E Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single/Double Silver Low Radiation Coated Glass,energysaving,environmentfriendly, best lighting decorative materials

Features of Clear Low-E Coated Glass:

In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

solid coatingswill unite with glass into one.

the same lifetime of silver coatings with glass, stable properties, long storage.

easy to process, dispose and store

natural color

no need of special treatment as the layers of insulating glass

conforming to the standard of GB T 18915.2-2008

Specifications of Clear Low-E Coated Glass:

biggest size: 3660*2440mm/3660*2134mm (size is subject to customization)

thickness: 4mm,5mm,6mm,8mm

Applications of Clear Low-E Coated Glass:

It is widely used for constructon, decoration, curtain walls, windows, etc.

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: List and characteristics of chimney glass flake cement

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale made of C- glass has excellent chemical durability.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- There's no problem with fiberglass mesh.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- Finished product protection: because the construction environment belongs to the pool irrigation, it is not conducive to the curing of epoxy forming, so it must take 48 hours curing time, to be fully cured after use.

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- Production process, ah, complex will be expensive - the main material is silicate

- Q: What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q: How to identify and select high quality insulating glass?

- At present, there are three kinds of insulating glass in China: (1) groove aluminum type single channel sealing; (two) groove aluminum double channel sealing; (three) compound sealant strip type insulating glass. Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so the kind of insulating glass gradually eliminated.

- Q: What kind of glass is smoked glass?

- * basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- FR4 is the pure epoxy board of NEMA standard. The normal color should be dark green. This is the color of epoxy. There are also yellow, generally called yellow FR4 called yellow material, white (green) called white material.FR4 is more expensive than epoxy board and fiberglass board cannot confirm the price.

- Q: The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass according to PBO (lead oxide) content is divided into high (24%PBO and above), medium (18%PBO), low (12%-16%PBO) three grades. Grading standards are similar to gold. International standard crystal glass is 24%PBO, so merchants will also call this class "24K"". If you go to buy, say some similar "jargon", the other party will feel that you are more adept, encountered illegal businesses, nor dare to fool you.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Clear Low-E Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords