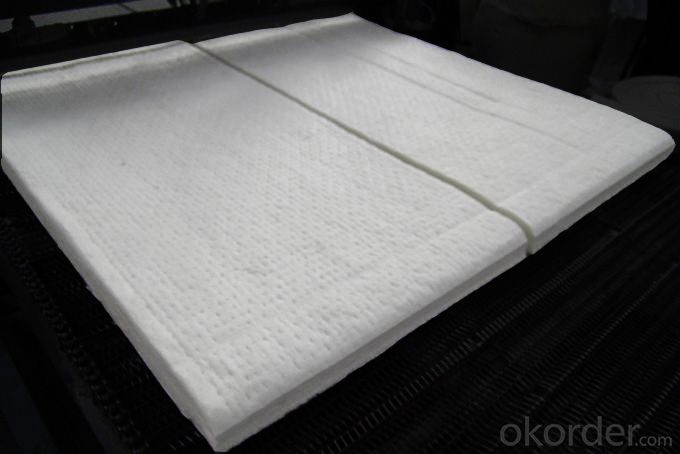

High Quality Ceramic Fiber Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 carton

- Supply Capability:

- 7000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Ceramic Fiber Blanket is a great energy saving product because of its superior insulating properties andadvantages of low heat storage and complete resistance to thermal shock. It is widely used as industrial insulation, high temperature insulation and in a variety of heat processing applications. Insulation Blanketis produced from high strength spun ceramic fibers and is needed to provide exceptional handling or construction strength. KT Refractories stocks large amounts of High quality Insulation Blanketin Houston TX: 2300°F or 2600°F Insulation Blanketwith different width or densities, or thickness.

Specification

Type | Common | Standard | Pure | High Aluminum | Zirconium |

Classification Temperature(℃) | 1100 | 1260 | 1260 | 1360 | 1430 |

Work Temperature(℃) | <1000< span=""> | 1050 | 1100 | 1200 | 1350 |

Color | White | Pure white | Pure white | Pure white | Pure white |

Density (kg/m3) | 96 / 128 | 96 / 128 | 96 / 128 | 128 / 160 | 128 / 160 |

Shrinkage on heating (%) (24 hours, density as 128/m3) | -4 (1000 ℃) | -3 (1000 ℃) | -3 (1100 ℃) | -3 (1250 ℃) | -3 (1350 ℃) |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400 ℃) 0.176(800 ℃) | 0.09(400 ℃) 0.176(800 ℃) | 0.09(400 ℃) 0.176(800 ℃) 0.22(1000 ℃) | 0.132(600 ℃) 0.22(1000 ℃) | 0.76(600 ℃) 0.22(1000 ℃) |

Tensile Strength (Mpa) (density as 128kg/m3) | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 |

Size | Thickness: 10mm, 20mm, 30mm, 50mm Diameter: 460mm Width: 610mm, 1220mm Length: 1500mm, 7200mm, 5000mm, 3600mm (Other sizes and shapes on request.) | ||||

Chemical Composition (%) | |||||

Type | Common | Standard | Pure | High Aluminum | Zirconium |

Al2O3 | 44 | 46 | 47--49 | 52-55 | 39-40 |

Al2O3 + SiO2 | 96 | 97 | 99 | 99 | - |

Al2O3 + SiO2 + Zro2 | - | - | - | - | 99 |

Zro2 | - | - | - | - | 15-17 |

Fe2O3 | <1.2< span=""> | <1.0< span=""> | 0.2 | 0.2 | 0.2 |

Na2O + K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Feature

Good anti-stripping performance

Good Sound-absorbing performance

Non-brittleness material, good flexibility

Excellent machining performance

Resistance to wind and erosion, long service life

Excellent heat insulation, fire prevention, sound absorption performance

Low thermal conductivity, low thermal capacity

Excellent thermal stability and good resistance to heat shock

Excellent tensile strength

Application

The industry kiln, heating device, high temperature pipe lining

Power boiler, gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating equipment lining

Fireproof and heat insulation for high building

High-grade household appliances thermal insulation device

High temperature filtration etc.

COMPANY PROFILE

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

- Q: i know a lot about various methods to straighten hair but they all seem to cause damage and can lead to hair lossIs there any way for me to straighten my hair without damaging it?

- life is almost a container of chocolatesa affordable, inconsiderate, perfunctory present that no person ever asks forUnreturnable using fact all you come back is yet another container of chocolatesso which you're caught with this undefinable whipped mint crap which you mindlessly wolf down while there is not something left to eatparticular, each now and then there's a peanut butter cup or an English toffeeyet they're long previous too quickly and the flavor isfleetingSo, you wind up with not something yet broken bits crammed with hardened jelly and the teeth-shattering nutsAnd once you're desperate sufficient to eat those, all you acquire left is an empty container crammed with ineffective brown paper wrappers.

- Q: I have a sweater that just continues to shed, I cannot get it to stop shedding, every time that I wear it, it sheds all over the placeI follow the washing instructions on the label but it just continues to shedAny ideads on how to get it to stop shedding?Thanks!

- You can use parchment paper on the panBut most recipes calling for it, I've seen, say to spray or grease the parchment paper.

- Q: No silly answersI'm making a scarf for a friend and I want to do a slanted lip design toward the endI have red 4-worsted yarn at home, but I was wondering whether I should use paint, nail polish, or is there a way to actually use that yarn to knit something inAny ideas?

- Painting on knitting, particularly bulky knitting, isn't likely to get you good resultsLuckily there is a way to knit in a colored pattern, with a technique called intarsiaPractice the tutorial below; once you learn to do intarsia with a given pattern, the next step is to make up your own patternIt's done with a chart, it's like graph paper but you can't use regular graph paper because knit stitches aren't exactly squareLuckily you can print it off the net for freeYou draw the pattern you want to have and then trace the it onto the knitter's graph paper by coloring in all the stitches (squares) that have to be the contrasting color to make your designThen you knit from that chart, each square representing a stitch and each row, obviously, representing a row of stitches.

- Q: i heated up my house to 83 degree's and within 20 minutes it dropped down to 63 degreesdoes that mean my house has no insulation between the walls? or do i have a very bad air leak

- Retrofitting energy efficiency into an older home is expensive, and only partially successful - there are so many ways for heat to leak out and inFirst, check the windows - adding storm windows or at least thin clear plastic on the outsides during winterNext, check for cold spots - elec outlets on exterior walls, exterior door frames, stove vent hood, fireplace chimney, etcA can of great stuff spray foam will do a lot of good, but once you open it, you have to use it all right now, or throw the rest away; so decide what you'll do and make preparations - remove cover plates from all light and plug openings on exterior walls, for example You can buy loose fill insulation pretty cheap at Lowe's and they will lend you a blower machineIf there's a crawl space, look under there - often the insulation is long goneThere, put batts, unfaced, as wide as the joists (I like R-19 at minimum - more if the joist spacing will accept it without crowding), and hold it up with wire, crisscrossed between joists and stapled inGreat idea to then cover it with tight fitting black poly 6 mil, again stapled well.

- Q: I have fine straight platinum blonde hair and my hair has no body to it, it's between my chin and my shoulders.What is a good shampoo? What is the best brush to use?

- A duvet and comforter are essentially, the same thingThey are either down or polyester filled and can be launderedYou can also put a duvet cover on either and just wash that regularlyA bedspread is just a bedcoverIt isn't designed to give much warmth and you need blankets underneath Target and Walmart both carry bedding at affordable prrices.

- Q: i only want to know about fiber blankets stopping my beads/other stuff from cracking easily

- challenging point try searching with google and yahoo this will help

- Q: Ceramic fiber blanket will not expand when heated?

- HLGX ceramic fiber blanket itself is composed of many micron diameter ceramic fiber perplexing interweaved, i.e. HLGX ceramic fiber blanket, whether it is the standard grade HLGX-212, grade HLGX-512 or containing zirconium maximum temperature of 1400 DEG C, they are porous materials with high porosity is more than 90%, so hot after contracting Huolong ceramic fiber blanket heating or expansion will be the equivalent pore off, will not be too obvious. This is from an experimental point of view.

- Q: I have constant constipation, and drinking coffee seems to helpI do put sugar and creamer in it, I just can't stand it blackI drink it throughout the day to help me.Thanks

- Not reallyIt is a fadI prefer the Egyptian cotton/polyester blend myself.

- Q: ok i have some old tie dye (from wal mart) and i was wondering if i could use it to dye hemp (i think i got it at wal mart too) the hemp is like yarn hempi think it would work, wouldnt it? thank you to you if you answer! : )

- CAKE MIX COOKIES (I make these at Christmastime for gift giving) White Cake Mix 2 Tablespoons water 2 eggs 1/2 cup cooking oil 1 teaspoon almond extract 1/2 cup chopped nuts powdered sugar Mix all ingredients, except powdered sugarDrop batter (about a teaspoon per cookie) into a bowl of powdered sugarRoll in sugar until it is an approximate shape of a ballPlace on a lightly greased cookie sheetBake at 350 degrees about 18 minutes, until lightly brownedCool on wire racksMakes about 4 dozen cookies(Use any flavoring or cake mix you desire…….substitute regular sugar for powdered)

Send your message to us

High Quality Ceramic Fiber Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 carton

- Supply Capability:

- 7000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords