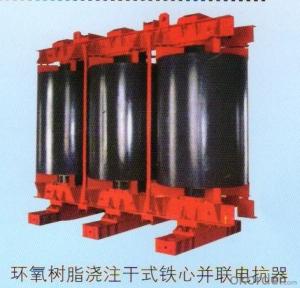

Cast Resin Transformers from SGB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Why cast resin transformers made by us?

The range of SGB-SMIT cast resin transformers includes power ratings up to 25 MVA and rated

insulation voltages up to 36 kV as well as converter, distribution and special transformers. With its

over 30 years of experience in the construction of cast resin transformers, SGB-SMIT‘s scope of

special expertise is one of the largest world-wide, a fact which is reflected by the extremely high

quality level such as our MTBF (mean time between failures) of over 2,400 years.

Thanks to their special design, SGB-SMIT cast resin transformers offer a range of features which, on

the one hand, distinguish them from other cast resin transformers in terms of technology and, on the

other hand, make them a highly reliable and extremely safe solution.

The operative benefits for you, our customer, are the following:

• Thanks to the multi-layer winding principle, high surge voltages and switching

voltages are handled safely.

• Cooling ducts provide thermal reserves and allow for overload.

• The use of glass-fibre reinforced plastics (GFK) in the encapsulated windings

provides resistance to temperature shocks.

• Long service lives are ensured.

With production starting in the late 1970‘s, SGB-SMIT were one of the first manufacturers of cast

resin transformers, thus we are able to offer our customers the benefit of our extensive experience

and know how. This extraordinary know-how is reflected by a especially high quality score, e.g. an

MTBF of over 2,400 years.

It goes without saying that SGB-SMIT cast resin transformers meet all the established

quality conditions: Fire classification F1 • Environmental class E2 • Climate classification C2

And as a matter of course, the product sector Cast-Resin Transformers at SGB-SMIT has been

certified according to ISO 9001 and ISO 14001.

The extremely high quality of SGB-SMIT cast resin transformers has a name: Uni|Q.

Uni|Q is synonymous with the special quality and test features which make our cast resin

transformers so unique:

• Several Decades of Experience

· Comprehensive operating experience world-wide including international production sites

· First-class international references in all sectors

· Ample know-how and long-term experience in the field of onshore wind power plants

including special cooling systems: Jet System

· Transformer system tailored to open sea conditions for offshore wind power plants with many

years of operating experience: Safe-System

· Optimum solutions for all industrial applications with extreme climate conditions – no matter

whether extremely hot or cold: All Climate Safe System

• Unique design

· The multi-layer winding is electrically the best and most reliable option. Thus, almost all oil

distribution transformer manufacturers apply this principle. Millions of these have been

securing the energy supply in many countries for several decades world-wide. SGB-SMIT is the

only manufacturer of cast resin transformers who uses this principle!

• Computerised monitoring of the production process

· Based on a precise analysis according to

automotive standards, all relevant production

parameters of each transformer are recorded

continuously and compared online to the

set-point values. The next production step

only follows if everything is found to be correct.

· This system makes it possible to achieve a

uniform level of quality over large production

quantities at all locations of the SGB-SMIT

Group on an international basis

- Q:Could this be potentially Electrokinesis?I am prone to having a LOT of static shocks. My computer freezes on me, my TV turns over by itself, my computer, Ipod, Phone turn off by themselves. My phone rings random people, if I put my finger about a centimeter over my touch screen on my Ipod it still works, the internet keeps disconnecting for meyou get the idea. Why does this happen? could it be out of control electrokinesis?

- It's just a bad day for you

- Q:can i sell magnetic contactor transformer 24vand where ?

- With an accurate description and a couple of good pictures, you can sell just about anything on OKorder. Don

- Q:I just recently bought a router that was recommended to me, Linksys WRT160N V3. I followed all the steps to connect and it works. the problem is (and i measured) i walked 34 3/16 feet away into my room and boom. no connection, and my laptop, nor my ps3 can find the router. the only thing in the way of my router and my equipment is 2 walls and a bathroom (yes a small apartment). did i buy a crappy router or is there a way to increase the range for this particular model, because i feel like i got ripped off. thanks for the help.Also i was thinking of maybe getting netgear instead, everyone else seems to think it's good i just don't have the cash. thanks for the help.

- First make sure the router is sited correctly. It needs to be as high as possible and clear of obstructions. This includes furniture, electrical equipment, metalwork and people. Definitely it should be above the level of the bath, as the plumbing will be earthed, and even plastic pipes containing water have a similar effect to earthed metal pipes. If the building has metal structures in the walls these area disaster for wireless signal. But if you get it out of line from those in the direction towards your machines it may solve the problem. A very small move can often change from no signal to full signal. Do not place it too close to any wall, reflected signal can cause signal cancelling at these frequencies. The machine should also be out of line with such obstructions. Is there a hot water tank in the way? another BIG wireless killer. If this fails you could fit a longer network cable to the router from the modem, since it is a cable router. I must admit I am not too impressed with Linksys lately, but it should work well enough at that distance. Anther option is to buy a wireless repeater which just connects to power, and place it between the router and the machines, this can be sited offset (in a different direction to the bathroom) and relays the signal. This could get your signal round whatever is obstructing signal.

- Q:give formulas and explanation both

- The input, output and efficiency relationships are the same. In one case we are talking about a mechanical system and in the other it's an electrical system.

- Q:i want to make a bulb on and off at intervals of say half an hour. readymade timers available in shops(india) costs much and does not support shorter intervals like half an hour. any cheaper electronic circuit which can do this control? from where can i get the circuit or its diagram?

- Depending on your skills, a CMOS 555 timer chip could probably drive a solid state switch (triac) for this interval although a more reliable timing, especially if you want exactly a 50% duty cycle, by feeding the timer output into a counter, so that the 555 cycles say 32 times (once a minute about) for each change of state of the selected output. Smaller cycle times are more stable.

- Q:Can I use an existing outlet in basement that's uses 14/3 wire and tap off of it to wire up a bathroom with 14/3 for light . Fann And one gfci outlet ?

- Yes, as long as the total draw on all outlets devices on the branch circuit does not exceed 15 Amperes - those wires should be protected by a breaker at that level in the electrical panel.

- Q:I am a freshman electrical engineering student and I have been given an assignment in which I have to write a 2 page paper about electrical engineering drawings. The paper has to include specific requirements for drawings in this field of engineering, any standards that are used, and any drawing codes that should be included in a typical drawing.Any help would be greatly appreciated.

- You sound pretty smart to be wearing a hat sideways.

- Q:I suspect my house electrical ground isn't working and had suffered equipment loss due to loss thunder strike.

- If the Lightning is hitting your house then you need to call in a profesional for insurance reasons. If it is hitting elsewhere and causing damage through you electrical lines or through your grounding system then you need to look into surge suppresion for your system.

- Q:Hello all!I know this is a crazy ideaBut I wanna try and build a mini automobile where a person could travel here and there :D I've already planned this but what are the basic requirements I need to engage in this project? I mean apart from the basic structure of the system, what are the main electronic devices and mechanical equipment I need to engage in this? I haven't done anything like this before but I think I have adequate experience. If someone could explain the basic concepts to build a mini automobile with the requirements I would be very grateful :)Thank you

- i'll tell you my Electrical point of view, you need to calculate the maximum load, and speed and choose the rating of the DC motor, and of course you need to design a driving circuit to control the speed of the motor, u need a gear to reduce the speed of the motor and get higher torque, that's so difficult for you look for something easier :P

- Q:If a 3 phase motor is driving a load say a gear box, compressor, or fan (Non Electrical piece of equipment) Does the load in this case gear box, compressor, or fan required a safety ground? The motor has its own safety ground

- If there is no electrical connections to them then grounding is optional.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast Resin Transformers from SGB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords