Carbon Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Eccentric Reducers

Features standards and products of our Butt-Welding Eccentric Reducers:

Features of Butt-Welding Eccentric Reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

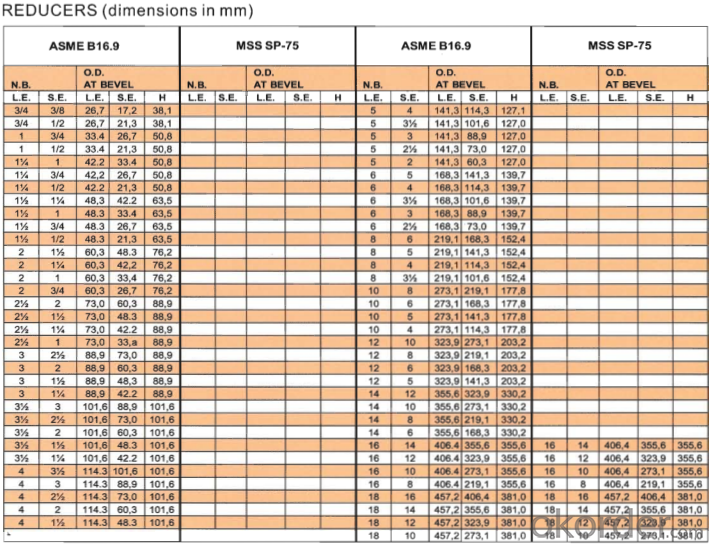

Standards of Butt-Welding Eccentric Reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Eccentric Reducers:

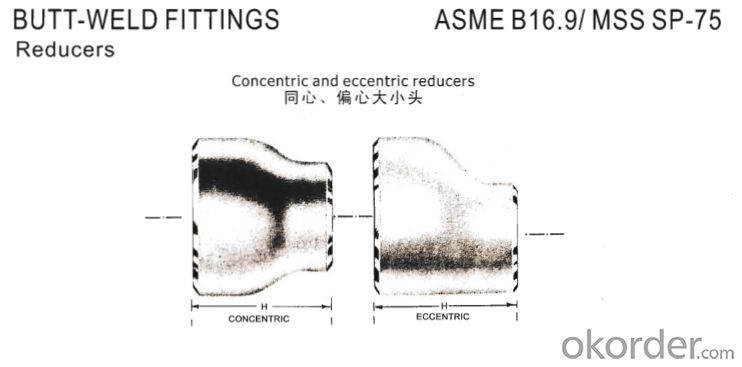

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Eccentric Reducers:

Packing of Butt-Welding Eccentric Reducers:

FAQ of Butt-Welding Eccentric Reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: this is so stupid and i know i cant get this chick but ill ask anyway. i have had an on and off crush on this girl for like 2 and half years. She has a boyfriend for like 5 years but they broke up a few times cause of him cheating.She barely knows me , i saw her at only a few parties but never talked to her. Heres where i got stupid and impatient just to get my name out there. I sent her a facebook request and she rejected it. Then i kept sending a request because i was annoyed and wanted to annoy her. basically im like obessessed cause the few times that i seen her, shes gorgeous and i need a way in. Im friends with all her friends which is a plus. im not a slouch either im gonna be a fireman soon and im good looking , i workout too but i have no confidence when it comes to her possibly cause shes too good for me or something. i kind of ruined my chances with the whole facebook thing but maybe someone can help me. thanks guys

- My barrel horse was barefoot for years but wasn't raced very often - mostly a trail horse back then. But when I started really racing, I noticed that practicing without shoes on versus with shoes made a difference in traction and her ability to perform. I used special shoes (rim shoes) that provide additional traction because we often ran in not-so-perfect arenas. But really, the traction was my only reason for shoes. I also currently lesson at a hunter/jumper barn. Only a few horses are shod. Their reasoning is based upon if the horse needs it for soundness issues. If not, they can still jump well without them, but with very good farrier work! Finally, I show pleasure horses (paints), and they all go barefoot. I do natural trimming which includes rounding the toe and a little more work for the farrier, but I have had no problems with my 3 show horses chipping or with soundness issues. Also, they are not supplemented for their hooves. I switched to barefoot because it seemed more natural. This is how the hoof was made to be! And because I have had fantastic results in doing so, I plan to keep them this way. Granted, I'm not saying that all horses should go barefoot, but for my needs and my horses needs, it is the way I plan on going from now on.

- Q: I have dining room chairs that have a resin like wood. any tips on how to strip and re-stain it? we got this dining room set and realized after we got it home that there was this resin like wood on the back of the chairs and on the columns of the table. We did notice that it is easy to strip off, but we are not sure on how to re-stain it. We did try to re-stain on a spot that is hard to see, but the stain seems to wipe off when it is dried.

- There is not app on iTunes that allows you to this. So you have to jailbreak your iPhone and get a software/program on Cydia either called iProtect or Lockdown iProtect allows you to locks individual apps and requires a passcode when someone clicks on, so you don't have to worry about people snooping around your phone when you let them borrow it.

- Q: I straighten it nearly everyday, and dye it. And it's starting to feel like straw, I use moisture conditioner and shampoo, by Aussie, but it isn't doing anything. What do you use to keep your hair hydrated? Something other than, don't dye it, or don't straighten it.thanks [:x

- Are you sure the alarms actually went off?

- Q: I was cooking earlier and my smoke detectors went off. I live in an apartment complex and have three alarms (one in the hallway, and one in each bedroom). My husband had to take the one in the hall and one of the alarms in a bedroom off and unplug the alarm completely. The one in the other bedroom at that time was not going off so he left it up. Yet, that alarm is blinking rapidly a green light. An hour or so later we tried to plug in the other two alarms, yet they won't stop going off once attached by a/c power. I can't figure out what I need to do, I am so tired of listening to this alarm and I am worried to unplug the only remaining working alarm. (even though it is flashing rapidly a green light)Any help is appreciated, thanks!

- Wow, that just doesn't make any sense. I would call a handyman immediately and see if there is a problem with your wiring. Depending on your abilities, I would disengage it from the house wiring and replace it with a standard battery powered smoke alarm. Whatever is wrong with it, it is not reliable and it needs repair or replacing.

- Q: The radiator hose blew on my car and water went all over the motor causing it to cut out when I was driving. The temperature gauge was on half way so I didn't think any major damage could have been done but I cleaned out all the water from around the coil packs and the spark plugs. The motor will turn over but won't fire. It sounds like it's firing on a couple of cylinders but not all. The motor is a nissan RB20DE. What could the problems be? I'm hoping its not as major as a head gasket or a cracked head.

- Triceps; skull crushers, biceps; bicep curl, quads; leg extensions, pecs; bench press, deltoid; shoulder press, trapezius; shrugs, hamstrings; lunges, glutes; squats. Best of luck. . .

- Q: What's the meaning of the pipe joint 14-M18*1.5? What's the thickness of the wall?

- The assembly of the sleeve type pipe joint (1) the most important part of the pre assembly of the sleeve type pipe joint directly affects the reliability of the seal. A dedicated preprocessor is usually required. The small diameter can be pre joint in a vise. The concrete method is to use a joint as the mother's body and press the nut and the sleeve onto the tube. The utility model mainly comprises a sleeve type through pipe joint, a clamping sleeve type end through connection head, a clamping sleeve type three way pipe joint and other patterns.

- Q: Has anyone (other than firefighters) ever been taught how to use fire extinguishers?

- If you've unplugged it and detached the cord, then reconnected the cords and tried it again and it still won't work, it's toast. Electric blankets used to last decades, but most current models have a lifespan that's exactly the length of the warranty. How's that for progress?

- Q: So not too long ago, I was watching the people in the kitchen at Carl's Jr making the food. I noticed they were using their bare hands. I thought they were supposed to be wearing gloves?

- Get help now. If what you say is true your mom sounds highly depressed and schizophrenic. Walk to your school and tell your counselor. Or google the police station's number and tell them all of this. You really need help, and so does your mom and brother. It may seem drastic but don't wait until things get worse. Get help immediately.

- Q: WHAT IS THE BASE USED IN FIRE extinguisher?

- Articles of clothing are easier to retrieve and the safety of athletes participating in mattress olympic events is thereby increased by eliminating the hazards of stubbing ones toe upon the footboard whilst entering the field of play allowing for greater range of motion without impedence of speed or longevity as it relates to the endurance of participants in said events.thankfully no drug screening is required by a committee.

- Q: water is made of hydrogen, a flammable gas, and oxygen, a gas necessary to fuel fires.

- Try Hot Topic It's mostly goth/punk

Send your message to us

Carbon Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches