Steel Pipe Fittings Butt-Welding Eccentric Reducers High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Eccentric Reducers

Features standards and products of our Butt-Welding Eccentric Reducers:

Features of Butt-Welding Eccentric Reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Eccentric Reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Eccentric Reducers:

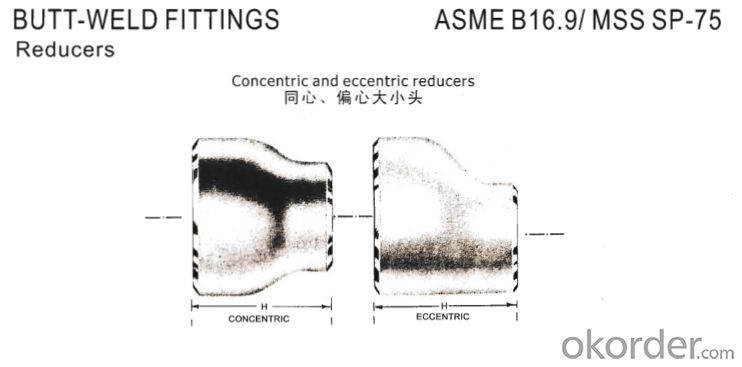

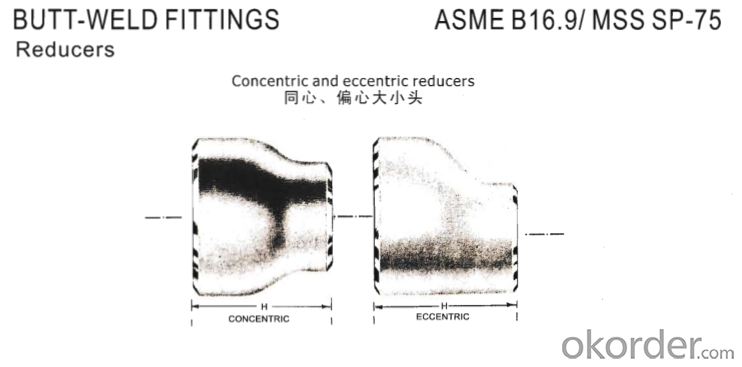

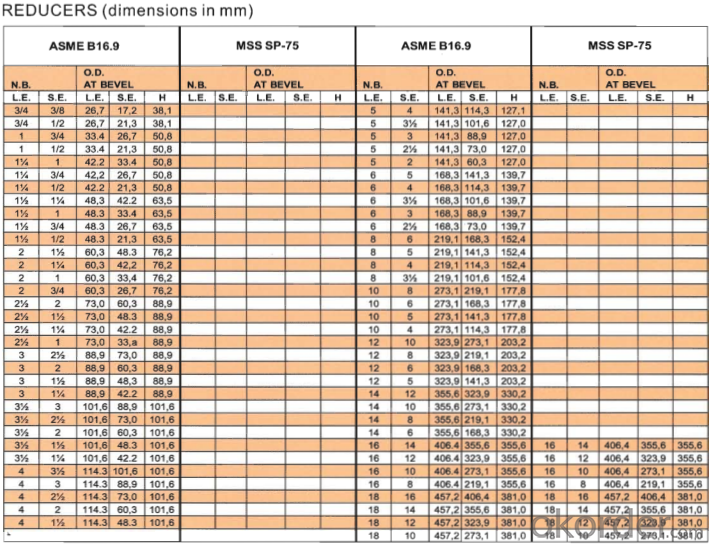

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Eccentric Reducers:

Packing of Butt-Welding Eccentric Reducers:

FAQ of Butt-Welding Eccentric Reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: A boulder became dislodged in the middle of the road, right at the entrance. Instead of removing it, they put caution tape around it. It was in a blind spot and I hit it at night when the tape was not visible. They are saying they aren t responsible. I can only file small claims if I have already spent the money to fix it and I do not have $3,000 to spend on this. What are my options? (I live in WA State)

- The water lost could serve a much larger population than that for a day. The problem is that it takes time to notify the water department or company, time to get the equipment out, and time to locate and turn the valve upstream of the break. It's not as simple as flipping a switch from your office. Those valves are big and not used often, so they tend to stick. The water suppliers work as quickly as they can. After all, it's their stock in trade that is being wasted and they are the ones who have to answer to the governmental agencies if there are fish kills.

- Q: I have dining room chairs that have a resin like wood. any tips on how to strip and re-stain it? we got this dining room set and realized after we got it home that there was this resin like wood on the back of the chairs and on the columns of the table. We did notice that it is easy to strip off, but we are not sure on how to re-stain it. We did try to re-stain on a spot that is hard to see, but the stain seems to wipe off when it is dried.

- I had a visual of me riding nekked on a white horse through town and guys throwing money.

- Q: i was wondering cuz we were messing around with one we found and my boyfriend said to make sure i dont breathe it in. i didnt try to and did and it wasn't much but i was curious if that's why he said not to(he hates people getting high) i wasnt trying to by the way. i'm just curious.

- probably a hang over from the Imperial system that doesn't match up with the Metric system or vice-versa. The only nuts I know of that are purposefully made not to match any normal bolts are the ones that secure the welding hose to the Oxygen cylinder of an oxyacetalene gas rig.

- Q: For 2 years now, I can not get into system information. Nothing appears. I have cleaned, checked the registry, and fully scanned for essential files. Everything else is fine. Any ideas?

- I like rubbing because it acts like an exfoliant. After washing and drying I apply a misting water tonic and then moisturizer to counteract any drying that may have occurred.

- Q: In my apartment complex, there are about half a dozen neighbors who continuously, despite warnings from the office, park in red fire zones. The weird part is, the office has stated that what most other neighbors are upset about is not this, but an excess of people parking who don't have permits. What gives?

- maybe mow strips at different times? so some of it is longer than the other so it would appear darker?

- Q: any fruit that has a fiber that can help resist fire like that of a fire blanket

- Let's see. You aren't the mother but you are going to risk (and lose) your life for someone else's child? How noble of you. Now see yourself as the mother. What stupid thing did YOU do? How can you avoid that, seeing by being shown these kind of scenarios you can act to make sure they don't happen, otherwise the cautions and alarming situation is wasted. What you saw was 3 different life threatening situations, with multiple incidents of the snake. I'd be writing down my dreams to find out more on this so it doesn't happen. The Creator provides these cautions to us, along with our ability to succeed in health, creativity, relationships etc. Use the analogies and metaphors wisely and you will avoid some or all of the problems.

- Q: I use an electric heater in my room, and every time I turn it on, or any electric heater for that matter I get really sick at my stomach and a headache and it's real bad too like reach for the trash can kind of bad. I just feel weird over all. and I almost know it's the heater because I've turned it off and the symptoms disappeared almost immediately (It also got cold really fast too) and I turned it back on same thing. I've tried this with several heaters. but I really have to have something because the outside temp is below zero I believe and this is an old house with poor insulation.and I know I don't have Carbon Monoxide poisoning because I DO have a Gas stove in my bathroom (The old kind too) that I leave burning constantly, but I can sit around that thing all day and not feel any different unless I shut the door for a shower then I might get a little light headed but that only happened to me once and I was in there for a LONG time. plus we have a brand new Carbon Monoxide detector right by it.

- You've answered your question already. The only reason for speed bumps is to keep drivers at or below the speed limit for that area. Usually to protect children and pedestrians.

- Q: The pipe that is attached under the sink in the bathroom is corroded ,it is also attached to the wall.We cant put the other pipe back on bc their is no more threads to attach the drain.

- C. in front of a public driveway You aren't supposed to block access in and out of a public driveway.

- Q: since i had a new filling done i have set of alarms in shops is that a coincedence

- Get a shark bite cap or shut of valve from a hardware store. They are a a new type of plumbing fitting that cost a few dolars each but require zero knowledge or experience to install. just get a cheap pipe cutter to make a smooth edge on the pipe and push the cap/connector/shutoff valve on. try bringing a piece of it with you to the store, for sizing. Compression fittings are also available that are simpler than learning to solder. these just require some wrenches and a nice clean cut pipe edge.

- Q: My ultimate favorite breed of horse is a Lusitano. im a HUGE dressage girl and really wants to (down the road) get a lusitano stud for dressage. yes there are plenty out there so finding one isnt the problem, neither is the price. i want a highly trained dressage horse. first of all are lusitano horses pretty hot?? and arent they known for the Roman nose?? i LOVE the ROMAN NOSE. any ways what do you think of the Lusitano?

- The hydrant or meter is on there property. Or they have a easement to have it there. If not you can cut the pipe. Best to quietly remove 2 inch's of rock. And replace with good top soil. And let the grass grow. It is becoming common for them to fill with sand or gravel. Check the property line and easements on it. Go from there. They are not allowed to put poles,meters, hydrants on private property. With out a easement. Why I can not put a pool were I wish on my property. Underground cable there. And they have a easement going back into the 40s. For it there.

Send your message to us

Steel Pipe Fittings Butt-Welding Eccentric Reducers High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords