Carbon Pipe Fittings Butt-Welding 90° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

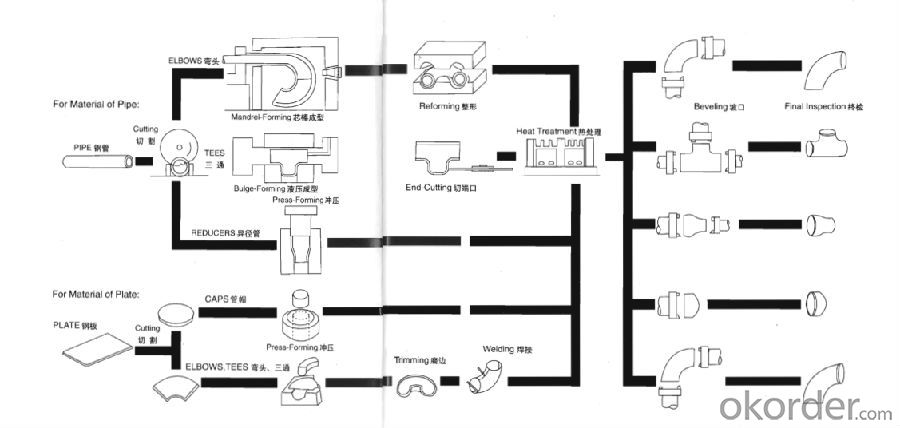

Manufacturing method and process:

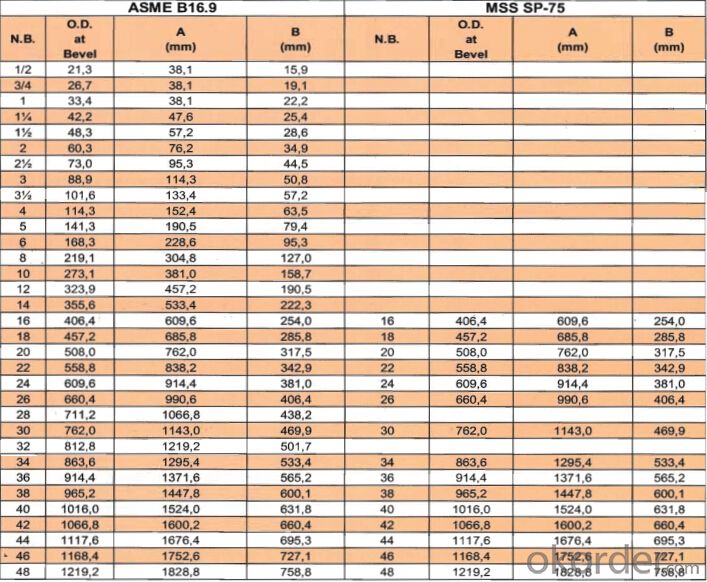

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

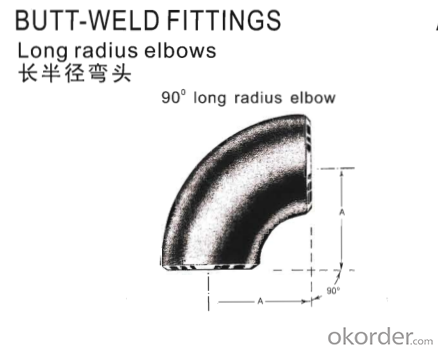

90° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: The nozzle of a fire hose ejects water with a speed of 30.0 m/s. The stream of water is aimed 35 degrees above the horizontal ground. Assume the nozzle is at ground level, and each water drop is in free-fall.a. Find the speed of a water drop at the highest point of its motion.b. What is the magnitude of the acceleration of a water drop at the highest point of its motion?c. How far from the nozzle will the stream of water land?

- just take the locks to a locksmith and get them rekeyed

- Q: He suggested picking upon a new curling iron or get my hair done at a hair salon I said no to both of these and then I thought of my mom and said i could roller set my hair And he said i have never seen you in rollers before and he bought me some I got back home and have not used my curling iron again as I now prefer putting my hair in curlers

- I'm not a big NASCAR fan, but I'm sure that you pretty much have to start out in amateur stockcar racing and win a lot. And, I'm sure it costs a bit of money but at the same time - your goal probably really is to get sponsors.

- Q: I am the most expensive in town, but it's also true that I offer cageless boarding, an over 400 square feet play room, free 2 walks a day and am a dog trainer/behavior consultant that is pet first aid certified. I also only accept 2-3 dogs so they can get the attention they deserve. Have toys, swimming pool for dogs, and offer 24/7 supervision. Just checking on thoughts for my pricing, thanks!

- The models used to predict head loss have no physical basis, should you be in the turbulent flow regime. They are curve-fitting to standardized experimental results of controlled experiments. Many flow conditions of turbulence are difficult to predict.

- Q: Paying child support kills children by Funding/Subsidizing the 1 KILLER of children: single-mother-households: Children from single-mother households, compared to children of two-parent families where the biological father is present, are more likely to go to prison by 20 times, to commit suicide by 5 times, to have behavioral problems by 20 times, to become rapists by 14 times, to run away by 32 times, to abuse chemical substances by 10 times, to drop out of high school by 9 times, to be seriously abused by 33 times, to be fatally abused by 73 times, to be one tenth as likely to get A's in school, and to [per Lenore Weitzman] have a 72% lower standard of living.This country, with its institutions, belongs to the people who inhabit it. Whenever they shall grow weary of the existing government, they can exercise their constitutional right of amending it, or their revolutionary right to dismember it or overthrow it. - Abraham Lincoln, First Inaugural Address, March 4, 1861 (1809-1865)

- as much as you want you would be rich but making the iron man suite is impossible because you would need a source of energy great enough to power the suit which would does not exist unless you can achieve cold fusion and somehow make it small enough to fit as an energy source for the suit

- Q: Which is the best CD scratch cleaner?? Please give me a tip to enhance the life of DVD-RW(DVD Rewriter)?Difference b/w DVD-R and DVD+R?

- That sounds like a good idea, although I would replace William regal with maybe randy orton, I love the shield, hope they get a wrestlemaina match

- Q: Basically when my alarm goes off, I wake up in a haze, but am not aware enough to know I have to actually GET UP and go to work.Anyone have any tricks for actually getting up when the alarm goes off?

- Synthetic resins are materials with similar properties to natural resins—viscous liquids capable of hardening. They are typically manufactured by esterification or soaping of organic compounds. The classic variety is epoxy resin, manufactured through polymerization-polyaddition or polycondensation reactions, used as a thermoset polymer for adhesives and composites. Epoxy resin is two times stronger than concrete, seamless and waterproof. As such it has been mainly in use for industrial flooring purposes since the 1960s. Since 2000, however, epoxy and polyurethane resins are used in interiors as well, mainly in Western Europe. One more category, which constitutes 75% of resins used, is unsaturated polyester resin. Ion exchange resin is another important class with application in water purification and catalysis of organic reactions. See also AT-10 Resin, melamine resin. Another synthetic polymer is also sometimes called by the same suffix, acetal resin. By contrast with the other synthetics, however, it has a simple chain structure with the repeat unit of form -[CH2O]-.

- Q: I have recieved a new sony ericsson t715 from 3 as part of an upgrade on my contract. Is the phone already locked to 3 or is it unlocked and able to use any network i want on it? I need to know because im selling it new, so i can't open the box to check.

- That has nothing to do with having faith in God like somebody else stated putting your seatbelt on in car and not standing in front of trains that is common sense God didn't say be stupid

- Q: Can the sleeve type pipe joint be disassembled and assembled several times?

- Some domestic manufacturers in Europe and the United States is the sleeve type pipe joint suppliers, their structure can be repeated disassembly; but some connector is a one-time pressure deformation, the joint group cannot be used repeatedly, or at least need to replace the components outside the card of the pipe, and the sealing surface of the belt assembly still need to check the qualified talents use up a nut by repeating

- Q: I always was puzzled by the weird rituals canines performed around plastic fire hydrants.

- Put salt on it, seriously

- Q: my truck just left me on the side of the road due to overheating. it had started hesitating and blowing white smoke while on idle until it started overheating and smoking white continuously. what do you think my problem is? my truck is a 2005 ford F250 diesel

- Well this didnt happen to me, but just a few mins ago my friend jewels broke up with my other friend, jon. Jewels broke up with jon by text msging him saying were over. no reasoning or anything. i think that was alittle harsh, seeing as he never did anything to her. he was always nice and polite and everything but he was one of those shy nice guys. she didnt like that, so it was over. harsh? yes.

Send your message to us

Carbon Pipe Fittings Butt-Welding 90° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords