Butterfly Valve DN150 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve consists of body ,stem ,disc , actuator (manual actuator, worm-gear actuator , aerodynamic actuator or electric actuator) , and wafer type butterfly valve can implement the process for turning on turning off and regulating the flow by the circumrotation of stem and disc that is droved by actuators.

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

e).Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

f).Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

g). Excellent sealing performance with no leakage. Long service life.

h). Wide selection of materials ,applicable for various media..

i). Flow curve tending to straight line. Excellent regulation performance.

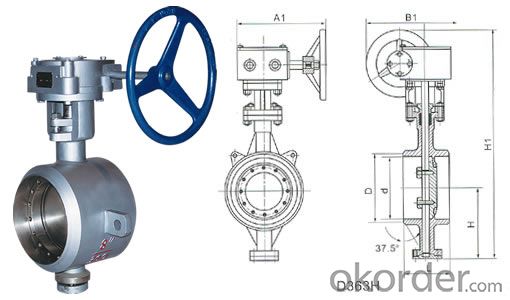

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: how to reset control valve with electron pneumatic positioner of (make) Instrument and system.?

- Control valves come with a spring g which keeps the valve in either the open or closed position, when there is no air pressure applied to the diaphragm of the valve actuator. For this reason, I'm unsure what you mean with 'reset the valve. The electro/pneumatic positioner is a device which applies the air pressure required to open (or close) the valve to the position the electric signal from the controller is calling for, rather than using an I/P transducer to output a 3 to 15 PSIG air pressure to the diaphragm. Sometimes an actuator requires more pressure than the normal 3 to 15 psig to move a sticky valve to the correct position. Edit your question to detail what is occurring, and I or someone else can give you a proper answer. TexMav

- Q: A reading from my 2002 ford explorer said insufficient flow from the EGR valve. Would it be possible to clean the valve or fix it or would I need to buy a whole new valve?

- Could be dirty, or it could be the egr solenoid failing

- Q: It looks like our toilet water shut off valve is leaking. We are trying to turn off the water by turning the lever on the hot water heater, but this only turned off the hot water. So the cold water is still not turned off? We thought the one lever at the hot water heater would turn it all off, but it didn't work. Is there actually a separate water shut off valve for cold water in my house? Help!!

- There is a cut off valve at the water meter.Before you get to deep in this,make sure the water is not running down the line from the tank it self.Dry the line coming out the tank with a paper towel just to make sure it is the valve leaking.Believe me,it can fool you.

- Q: 12 valve

- Un plug the vacuum hose on top of the valve, loosen and remove the big tube nut on the bottom of the valve, I have found if you hit it sharply with a hammer 3 or 4 times before you try to loosen it won't break the valve off, once the tube nut is undone remove the 2 bolts holding the EGR valve to the intake manifold. Remove and discard the gasket and install the new valve in the reverse order. If the tube nut still won't come loose try heating it with a torch, if it's really rusted on you might have to replace the EGR tub along with the valve.

- Q: I've been told that I need to replace a clogged expanssion valve on my '96 toyota camry.A friend said he would properly recharge the system if i replaced the parts needed .I can't ask him where it is because he's out of town for a little while. I also need to replace the drier ,but it's obvious where it is.Please help me.

- the expansion valve is usually located inside the line next to the accumulator/dryer. If you drain the system, and remove the accumulator, look inside the line that leads into it, and it should be stuffed in the line. If you see one inside the line, it is actually called an orifice tube, but has the same function as an expansion valve. Actually, expansion valves are usually used in large vans with a rear a/c evaporator unit. If it is an external valve it should be next to the accumulator as well. The purpose of this valve/tube is to create high pressure gas out of low pressure liquid freon. These usually become clogged with debris after the compressor's pistons break apart and contaminate the system. If you find little metal shavings in the tube, or valve, your compressor was either replaced at one time, or is bad now.

- Q: i have a 04 kia sadona i have been having issues with the van overheating someone told me to open the bleeder valve and let it drain then refill leave the valve open and if i see bubbles in the radiator than its a blown head gasket. is this true? is there a bleeder valve on this and if so where is it located? its not on the thermostat housing i allready replaced the thermostat.

- Remove the radiator cap when cold and run the engine. Have someone rev the engine while the transmission is in park (with the parking brake ON), and you watch in the top of the radiator for bubbles. It may take a few seconds from the time they rev till the bubbles rise to the top.

- Q: I have a 1991 Toyota Supra turbo that has to have the valve stem seals replaced.It puffs white smoke upon start up,but it goes away.Just curious if the seals can be replaced while the head is still on the motor in the car.

- yes valve stem seals can be replaced with head on, requires cam removal and cil. pressurised with air to hold valves in place whike vakve spring is removed seal changed and spring and keepers reinstalled. If you already had this done and it still smokes chances are you have a bad valve guide.

- Q: I been playing the trombone for 6 years, do you think i could learn to play the baritone easily,which baritone is easier,3 valve or 4 valve.

- Some baritones have 3 valves, but the others have 4. The 3 valved ones are baritones and then the 4 valved ones are euphoniums.

- Q: Is there a relationship?

- From personal experience yes it can. My mothers hemoglobin dropped down to 8.0. The Dr said it was because of her stenosis in her aortic valve causing her to bleed in her abdomen. She had her heart surgery and it came back up, just like the Dr said it would.

- Q: like they say on 4 strokes you gotta go get valve jobs, and they cost bout 300 they say? well what does the mechanic do? can it be done at home and your just adjusting them?

- A okorder /

Send your message to us

Butterfly Valve DN150 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords