Ball Valve For Heating SupplyDN 10 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

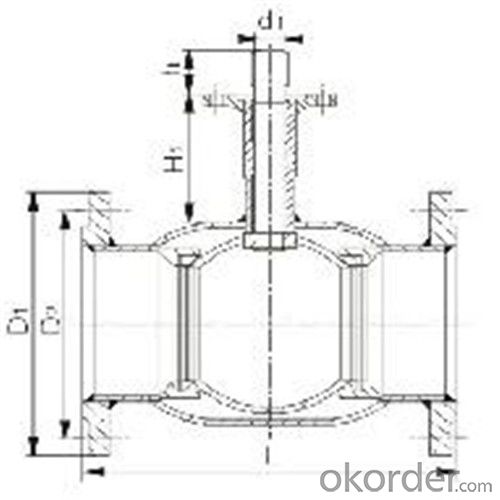

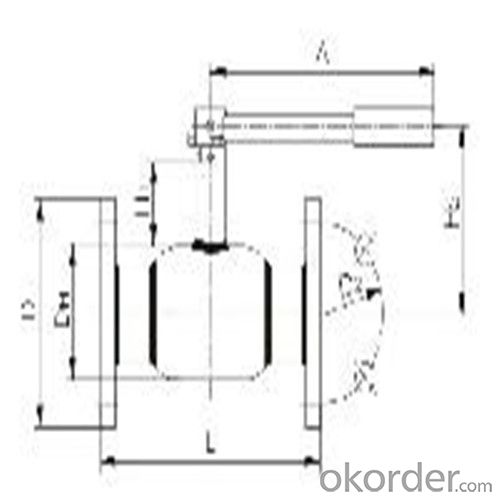

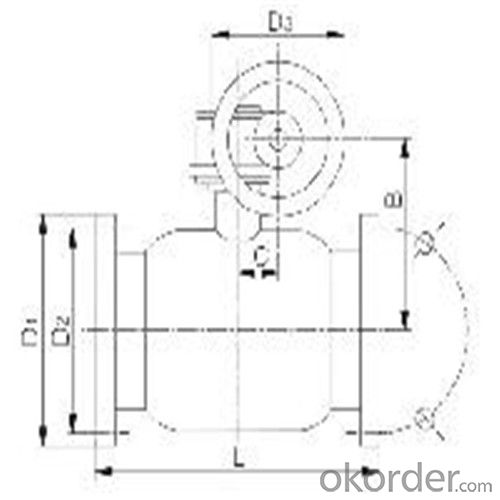

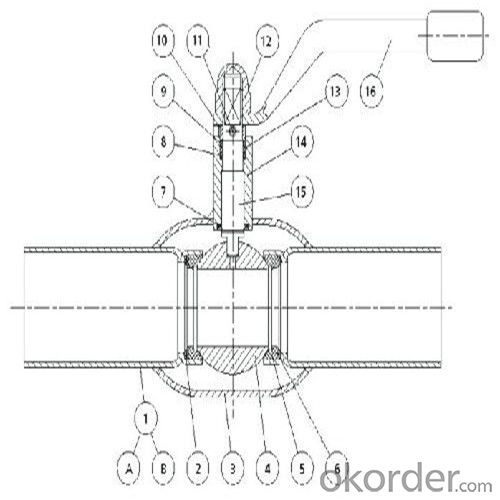

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: What is the best procedure to check/adjust valve clearances? This engine is a perkins diesel inside of a cat generator. I know that he exhaust valve is .018 and the intake valve is .008.

- Adam S, you're both right and wrong as far as needing to adjust valves. I changed 2 shims in 100,000 miles on my Kawasaki KZ1000, but my 1300 Kaw touring bike with nearly identical valve train needs checking and adjuuting every 6,000 miles or so. Go figure. Kneedragger, since your bike requires manual adjustment, you're valve train is either going to have a rockerarm type system with threaded screws and locknuts (easy) or use shims of various thicknesses to adjust the clearance (harder). Some have the shim on top of the 'bucket that covers the valve spring. With these, you will need a small, rather inexpensive tool specifically made for your model engine to compress the spring, allowing you to remove the shim. Other engines have the shim under the bucket, requiring you to remove the camshaft to change the shim. No special tools needed here, but reinstalling the camshafts correctly is absolutely vital. While this proceduere sounds rather intimidating, just remember that checking is all that may be necessary and no adjustments will need to be made. To check clearances, the idea is to turn the camshaft to that the cam lobe is pointing away from the valve and then measure the clearance with a feeler gauge and see how that compares to the recommended clearances. On shim type, clearances nearly always tighten and if the clearance is too little, you will need to install a thinner shim. I write down the clearance for each valve each time I check the clearances. If one valve tightens up faster than the others, this will give you a heads up to a possible future problem. Or, you may find they are ok this time but at the next check, you find some that need adjustment and will decide to take it to the shop that time. After a few checks and recording the clearances, you'll get a pretty good feel for how often you need to check them again. If you decide to do it yourself, by all means, get a shop manual.

- Q: Is it posible there is underground valves? I looked all over my yard and can only find2 valves.???

- Yes, electric valves are set on the Mainline which is under pressure. Usually in a loop around the home with the valves set where the zone starts. Some are designed to have a short mainline with the valves set in a large box next to a vacuum breaker. All valves need wires that run from the clock. Sorbet can be found with a metal detector if you simply can't find them. You can also set them to go off manually time delayed a few minutes, enough to go listen to hear the valve opening.

- Q: Where is the Canister vent shut valve located on a 2003 honda crv

- difficult step. try searching in search engines like google. that will can help!

- Q: the blow off valve has a hose that goes to the intake. Do you need that hose.

- if you want it to operate properly the yes you will need it. The valves are also adustable but you need a tech manual to and special tool to do it propperly dont just guess at its setting rather know it. I assume the picture i looked at was your engine. Unless you like taking chaces i would recomend you put your timing belt cover back in place. If anything should get in there between your t-belt and gears or pullys the belt could be damaged and if it does get damaged you could damage the valves in the event of t-belt failure. I know people like to see the belt and gears moving and if that is what you are wanting i would suggest installing one of the clear t-belt covers that are available. unfortunatly i do not know who makes them. if you cant find out go to a car show and talk to gear heads that have them on there cars.

- Q: I've been told that I need to replace a clogged expanssion valve on my '96 toyota camry.A friend said he would properly recharge the system if i replaced the parts needed .I can't ask him where it is because he's out of town for a little while. I also need to replace the drier ,but it's obvious where it is.Please help me.

- the expansion valve is usually located inside the line next to the accumulator/dryer. If you drain the system, and remove the accumulator, look inside the line that leads into it, and it should be stuffed in the line. If you see one inside the line, it is actually called an orifice tube, but has the same function as an expansion valve. Actually, expansion valves are usually used in large vans with a rear a/c evaporator unit. If it is an external valve it should be next to the accumulator as well. The purpose of this valve/tube is to create high pressure gas out of low pressure liquid freon. These usually become clogged with debris after the compressor's pistons break apart and contaminate the system. If you find little metal shavings in the tube, or valve, your compressor was either replaced at one time, or is bad now.

- Q: I got a french horn, but don't know if I can just use the valve oil I use for my trumpet. please help, thnx in advance :D

- Simply said: nope

- Q: I have a question about my car. The mechanic told me that my valve body needed to be rebuilt. However I read that the valve body is a sensor that tells the car when to shift gears. Now my car is a semi automatic so I can shift gears myself! I was wondering if someone could tell me whether it was still necessary to rebuild it if I'm going to be shifting gears myself? I just don't want to mess up the valve body even more and eventually have to get a whole new transmission!

- Its an electrically shifted automatic. The valve body is not a sensor it is the valving system that sends fluid to different parts of the transmission to shift gears. The solenoids on the valve body move the valves dependant on what the computer tells it to do. The paddles or shifter you have do not go to the transmission but to the ECU and the ECU decides what to actually do with the transmission. It does not matter if you shift it or let it do it its self if the transmission is going out it needs work or rebuilt, it WILL fail sooner or later and leave you stranded. So you either need to get it rebuilt or get another transmission. If you drive it until it fail you will need another unit, if you fix it now yours might be able to be saved.

- Q: I have a trumpet, but unintentionally dropped it. When I started playing, I noticed that the first valve was very sticky. Therefore, I decided to put some oil on it. Despite the oil helping a lot, the valves are still sticking a bit when I push them down, as the key still stays in the valve for a few second before coming up again. It could possibly have a slight dent, but when I opened the valve, I did not see any damage at all. Are there any suggestions? And if it is dented how much would it cost to repair it?

- My valves have had many issues over the past few years. Your problem is either 1. horn is dirty 2. there is a tiny dent (even 1/2mm is enough to stop the valve, happened to me last month). If your horn is dirty, there are plenty of youtube videos on how; it generally involves using water and rising all the gunk out. You could also have too much oil buildup. If there is a dent, don't even try to repair it yourself--it is waaaaay to hard, and you'll ruin the instrument even more. Take it to the store; it should only cost $20-30. I suggest you clean the trumpet first and then try to get it fixed if it is not good.

- Q: The time has come to re shim my 06 450, and I am having a small problem (I think anyway). The exhaust valves have decreased to below the required spec and need to be replaced with thinner shims (as is usually the case), but the left intake valve has for some reason increased its valve clearance (from 0.16mm to 0.23mm). Is it normal for the valve clearance to increase? I thought they would only decrease... Any ideas? Unless the valve is being held open by something. Many thanks, Jim

- The valve seats in the head take a constant pounding when the valves close - causing the valves to move up into the head and tighten the valve clearance. Carbon build up on the valve seats and valves will hold the valves open a fraction (unnoticeable in the engine's performance) - which will loosen the clearance.

- Q: we are having diffaculty with our spa and our jacuzzi. sometimes when we try and heat the spa the pool gets heated.first of all we would like to make sure the valve diagram is right because sometimes also the spa dumps about half into the pool. frustfrated can any one help?

- You have one or more faulty valves or you've got them turned the wrong way for the operation you want. You also may have a check valve that's going bad. The problem is that I'd have to see the setup around the pump and filter to even get an idea of what goes where. My pool has electric activators for the valves that allow automatic operation from inside the house. I adjusted one incorrectly once and it activated the valve backwards, and I had to readjust it.

Send your message to us

Ball Valve For Heating SupplyDN 10 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords