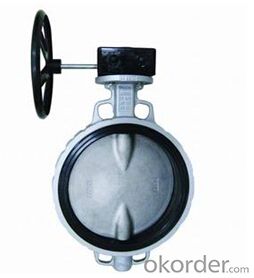

Butterfly Valve Turbine Type DN250 with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

2.Main Features of the Manual Wafer Butterfly Valve

1.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

2. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

3. Excellent sealing performance with no leakage. Long service life.

4. Wide selection of materials ,applicable for various media..

5. Flow curve tending to straight line. Excellent regulation performance.

6. Bubbles-tight sealing with no leakage under the pressure test

7. Wide selection of materials, applicable to various mediums

3.Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

Size: DN50-DN1000

End flange: ANSI B 16.1,EN1092,AS2129

Face to face: ANSI B 16.10

Top flange: ISO 5211

Normal pressure: PN1.0/1.6MPa(150/200PSI)

Body: CI/DI/WCB/ALB/CF8/CF8M

Disc: DI/ALB/Rubber lined Disc/1.2501/1.4529/CF8/Hastelloy Alloy/Monel

Suitable temperature: -10~120

Medium: Fresh water, sewage, sea water, air, vapor, food, medicine, oils, alkalis, salt etc.

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

- Q: hey...im kinda confusedis cochlear an artificial valve???and if not..what is an artificial valve??

- The cochlea is the auditory portion of the inner ear. A cochlear implant (CI) is a surgically implanted electronic device that provides a sense of sound to a person who is profoundly deaf or severely hard of hearing. The cochlear implant is often referred to as a bionic ear. An artificial heart valve is a device implanted in the heart of a patient with heart valvular disease. When one of the four heart valves malfunctions, the medical choice may be to replace the natural valve with an artificial valve. This requires open-heart surgery.

- Q: A diabetic patient undergone CABG having aortic valve problem.Cardiologist suggested valve replacement

- Can be cured by valve replacement... alternatively, if you can't/won't go through open heart surgery then you may be able to get valvuloplasty. A balloon is used to stretch the valve open. This does not last nearly as long as replacement, but avoids surgery. A third alternative would be to contact one of the percutaneous valve REPLACEMENT centers (Mayo, Cleveland Clinic, Columbia). This is an experimental procedure which replaces the valve using catheters instead of surgery. Advice offered here is not meant to be a replacement for proper evaluation and examination by a qualified medical professional and should not be construed as such.

- Q: my pcv valve tube is broken in half I replaced it with a rubber hose does it have to be whole

- The PCV valve is part of the engines emission control system. It controls the evacuation of the crankcase by applying engine vacuum to the crankcase and introducing the vapors drawn off into the engine. If the PCV valve and especially it's hose cracks or breaks, the engine will have a bad vacuum leak. The engine will loose a great deal of power. Many transmissions have a vacuum modulator that adjusts the shift points based upon engine vacuum levels. Normally low vacuum is associated with WOT (Wide Open Throttle) and so the tranny will delay upshifts when WOT is detected. Astrobuf

- Q: Our water heater (bought in 2007 so still fairly new still under warranty luckily) seems to release water from the pressure release valve quite frequently. Everyone seems to say that it shouldn't do it often and ours probably does it a couple times per day. 2 main questions - 1. Is there really a risk of too much pressure building up and the water heater exploding (that's what the sales guy at Lowe's said) and 2. Any idea what the problem might be/what we should check out?

- Two possibilities: When cold water is heated by the water heater it expands. In most houses the tiny bit of extra volume caused by this expansion flows back out the main line toward the street and the water pressure in your home remains constant. Some homes get such high water pressure from the utility that a pressure regulator valve is added where the water main enters the house. But pressure regulators are, by nature, backflow preventers. So now the small increase in volume from heating water results in a large increase in pressure - which is bled off by the Watts valve on your water heater. The only problem is that Watts valves are designed to operate very infrequently and only in an overpressure emergency. Yours is operating multiple times per day and functioning as a pressure control rather than as an emergency release. This can lead to premature fialure and it cn be dangerous. If you have a pressure regulator or a backflow prevention valve on your water main, ten you must have a properly installed expansion tank. The other possibility is that the Watts valve is starting to fail and should be replaced - they normally last the life of the water heater - but you may have gotten a 'bad' one. So, check for a pressure regualtor or backflow preventer and if you have you get a pressure tank, otherwise try just installing a new Watts valve.

- Q: how do i adjust the valve lash my book sys to torque to 136 in lbs but my wrench is only in ft lbs

- valve lash is a small gap between the rocker arm and the valve stem as the engine heats up the gap gets tighter due to expansion of valve train parts. To set the lash correctly find the gap that is recommended and use a feeler gauge to set. loosen the jam nut that holds the adjustable screw and set the screw to point where the guage has a slight drag on it. all this is done at the rocker arm and takes practice to get the feel of it. This must be done while the valves ARE CLOSED and the engine rotated to the correct position for that cylinder. Once the gap is set using the feeler guage, hold the adjustable screw still and tighten the jamb nut to the in./lbs. speced. In./lbs are a smaller value than ft/lbs. Find a torque wrench that has the smaller increments. If your not sure, find someone who HAS done this before and get them to assist you. Again, it must be done with the engine rotated to the correct spot. Usually around TDC for that cylinder being adjusted. Once set, test again with the feeler guage and see if the lash changed during the tightening of the jamb nut. If so, set again till lash has a slight drag. This means that you can slide the feeler guage in the gap and its not to loose nor to tight

- Q: Hi, I was wondering if it takes a minute or two for the water to actually turn on after turning the valve? I've turned it as far as I can counter-clockwise but there's still no water. Is there something else that needs to be done to get the water back?

- after turning the valve back on. Is there another valve upstream that was turned off as well? +

- Q: Hey guys Itook my car to mechanic because my engine light was on and the code showd that it was unsufficient egr lift or something like that....they had changed the egr valve before so this time they said there was carbon build up and they cleaned it and my car runs great now. i don't have problem with accelaration and the engine doesn't stall when i stop, BUT the light came on again and still shows the same code. I am sick of it!!! anybody knows what else could it be? It's 94 honda accord with 140 000 miles on it.

- The hose may puncture some where,their could lose tappet cover you could have blown inlet gasket.Regards Martin.

- Q: okay so i recently brought a trumpet and the valve keys were getting stuck. i used the valve oil and it worked. but then when i put the valve key back in and tried blowing through no sound came out. i think it's because i didnt put it back in right. now my question is how do i put it in right? i tried everything but it's still not making a sound. thanks,

- The first thing you should check is the order of the valves. take them all out and look on the sides of them for a number. One should have a 1 on it, another will have a 3 and the other one will probably be unmarked but that's obviously the one in the middle. On the outside of your trumpet there will be a 1 and a 3. The valve with the 1 on it goes in the slot that has a 1 on the outside, etc. Make sure you put these in right. if it's still not playing after you put the valves in and they're secured, twist the tops of the valves where the pearls are clockwise until they don't turn anymore. This should fix your problem.

- Q: i got a filler neck for my dodge dakota and was wondering how to put it on. can anyone send me a link or help me. and also what does my EGR valve look like and i cant seem to find a new one not even at the dealer. i was told to clean it how do i do this. can someone send me a link or pic what it look like. thanks

- The VECI decal map under your hodd will show you EXACTLY where your EGR valve is. You may need a magnifying glass. The valve can be removed and cleaned with Gum-out or foaming cleaner (amsoil). When you are done, re-install the valve. While you are getting ambitious, clean your throttle body and plate, and the IDLE AIR CONTROL VALVE. A dirty IAC is the most prominant reason for the EGR valve to clog up. Running Gum-out through your intake system will clean out your O2 sensors, as well. Good luck!!

- Q: I am looking at buying a 2001 Pontiac Bonneville and the guy said the car's check engine light says it had a problem with the EGR valve and so he bipassed it somehow. He said a EGR valve isn't needed. Is this valve very important or needed? What does it do? Thanks

- Yes it's vital for the car to run right and for smog or emissions testing too. I'd highly wonder about that car bec what else did he by pass. If you've not read the ECM's codes how do you know the engine light isn't on due to EGR valve and other faults with car. Best of luck and I hope this helps

Send your message to us

Butterfly Valve Turbine Type DN250 with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords