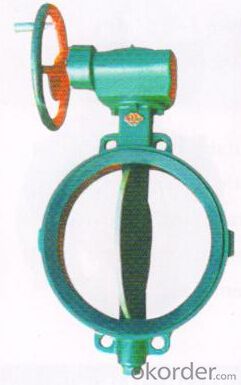

DN500 Turbine Type Butterfly Valve with Hand wheel BS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General valve using the market long-term, widespread Water Leakage, rust phenomenon, soft sealing gate valve produced by the introduction of foreign advanced technology of the enterprise. To overcome the poor sealing gate valve, general elastic fatigue, rust and other defects. Soft sealing gate valve is a traditional valve replacement products, the compensation effect of using flexible gate produce small deformation, achieve good sealing effect, the valve has a light switch, reliable sealing, good elastic memory and long service life and other significant advantages, can be widely used in water, sewage, construction, food, medicine, metallurgy, electric power, textile, energy systems, fluid pipeline regulation and closure devices as.

The characteristics of:

- flat style seat

The traditional control valve often pass after washing due to foreign objects such as stone, wood, cement, paper, and other debris deposited on the valve at the end of the groove. Close but not close easily lead to the formation of Water Leakage phenomenon, the lower part of the soft sealing gate valve with water using the same flat design, easy to siltation caused by debris, the fluid unimpeded.

And the overall package glue

The valve plate is made of high-quality rubber overall, the outsourcing of plastic, making the domestic first-class rubber vulcanization vulcanization after the valve plate to ensure accurate geometry, and the rubber and ductile iron gate is connected firmly, not easy to fall off and good elastic memory.

And corrosion resistance

The valve body adopts epoxy coating powder, can prevent the corrosion and rust, and can be used for sewage systems.

And not easy to break

Traditional cast iron garden gate often hit foreign objects, collision or overlap caused by the fracture phenomenon. Because the valve to switch to ductile iron, this is the case already significantly reduced.

Three "O" ring seal

As the valve stem with three "0" ring ring seal design, can reduce friction when the switch is greatly reduced, Water Leakage phenomenon and can cut off the water supply construction not replace sealing ring.

And help to drink

Due to the internal body to non-toxic epoxy resin coating, gate of the inner and outer surfaces are completely coated with rubber and can not rust or corrosion of water available to drink.

- Casting valve

Valve body casting, precise geometry makes the body without any internal finishing to ensure that the valve seal.

And light weight

The valve is made of ductile cast, lighter in weight than conventional gate weight about 20%-30%. Convenient installation and repair.

Overview:

General valve using the market long-term, widespread Water Leakage, rust phenomenon, soft sealing gate valve produced by the introduction of foreign advanced technology of the enterprise. To overcome the poor sealing gate valve, general elastic fatigue, rust and other defects. Soft sealing gate valve is a traditional valve replacement products, the compensation effect of using flexible gate produce small deformation, achieve good sealing effect, the valve has a light switch, reliable sealing, good elastic memory and long service life and other significant advantages, can be widely used in water, sewage, construction, food, medicine, metallurgy, electric power, textile, energy systems, fluid pipeline regulation and closure devices as.

The characteristics of:

- flat style seat

The traditional control valve often pass after washing due to foreign objects such as stone, wood, cement, paper, and other debris deposited on the valve at the end of the groove. Close but not close easily lead to the formation of Water Leakage phenomenon, the lower part of the soft sealing gate valve with water using the same flat design, easy to siltation caused by debris, the fluid unimpeded.

And the overall package glue

The valve plate is made of high-quality rubber overall, the outsourcing of plastic, making the domestic first-class rubber vulcanization vulcanization after the valve plate to ensure accurate geometry, and the rubber and ductile iron gate is connected firmly, not easy to fall off and good elastic memory.

And corrosion resistance

The valve body adopts epoxy coating powder, can prevent the corrosion and rust, and can be used for sewage systems.

And not easy to break

Traditional cast iron garden gate often hit foreign objects, collision or overlap caused by the fracture phenomenon. Because the valve to switch to ductile iron, this is the case already significantly reduced.

Three "O" ring seal

As the valve stem with three "0" ring ring seal design, can reduce friction when the switch is greatly reduced, Water Leakage phenomenon and can cut off the water supply construction not replace sealing ring.

And help to drink

Due to the internal body to non-toxic epoxy resin coating, gate of the inner and outer surfaces are completely coated with rubber and can not rust or corrosion of water available to drink.

- Casting valve

Valve body casting, precise geometry makes the body without any internal finishing to ensure that the valve seal.

And light weight

The valve is made of ductile cast, lighter in weight than conventional gate weight about 20%-30%. Convenient installation and repair.

- Q: 1998 Ford Crown Victoria LX 4.6L Use 89 Octane BP, Shell, Chevron gas. When the engine is under stress(acceleration or going up incline) the engine sounds like the valves are chattering. I can increase the rpm's and the chattering goes away. Had the same problem with 95 Thunderbird 4.6 and have heard other ford cars going down the road with this problem. Air leak? Don't really want to use higher octane due to gas prices and possible engine damage. Also, in the thunderbird, i used a bottle of octane boost and the next day a valve spring broke. Was the octane boost a possible cause?

- it is not valve chatter, it is called Pinging, it is a fairly common problem, what it is caused by is hot spots in the engine, or by overly advanced spark timing, i would check your base timing, perhaps even back it off a degree or two, i would also run a bottle of marvel mystery oil, or gm top engine cleaner through a vacuum line to burn out the crud that has built up, the sum total of these repairs: about 15 bucks, the savings: your engine! as for your t-bird, it was the pinging that broke the valve spring, not the tank of hi octane. hope this helps

- Q: Can someone please help me on this anatomy question:Describe the physical similarities and differences in the structure of the AV valves and the semilunar valves.Thanks

- The two atrioventricular (AV) valves ensure blood flows from the atria to the ventricles, and not the other way. These are large, multicusped valves that prevent backflow from the ventricles into the atria during systole. They are anchored to the wall of the ventricle by chordae tendinae, that prevent the valve from inverting. The two semilunar (SL) valves are present in the arteries leaving the heart, and they prevent blood flowing back from the arteries into the ventricles. These are positioned on the pulmonary artery and the aorta. These valves do not have chordae tendinae, but are more similar to valves in veins.

- Q: I recently converted my furnace from l.p. gas to natural gas. It's been maybe two weeks of me troubleshooting and replacing. I have a new gas valve and transformer in the furnace. There is 24v running to the valve and it clicks to open but no gas comes out. I have exhausted all my options with the mechanical/electrical components on the furnace. I have bled the valve to be sure that there was gas making it to the inlet side. Does anyone have an idea as to why the valve stopped opening once I converted it over?

- I don't know if this will help without seeing your furnace but this is similar to what happened when I light ours in the fall.Where the pilot light is if you have one there is a wire sensor and that gets dirty sometimes and needs cleaned at the tip by the pilot,on ours it connects to the gas valve and signals it to open.Good luck to you hope this helps,it also could be a bad valve.

- Q: If I buy one of those Presta valve adapters can I just screw it on and leave it on while I ride? Will I lose air pressure at to fast of a rate?

- Nope! I always ride with one screwed onto each tire. The schrader adapter screws over the presta. Always good to have one incase you're near a gas station and may need air.

- Q: I want to reduce the prssure of a liquid flow (ethanol) from 16.7 atm to 1.2 atm? Do I need more than one valve?

- One control valve can reduce pressure, as long as there is always a significant flow through it. The main reason for using more than one valve is usually to reduce or prevent cavitation caused by a large pressure change through a given valve. Ethanol has a pretty high vapor pressure, so cavitation might be a problem. Control valve manufacturers usually provide design guides for their valve trim choices (often in software form) that lead you through the choices and requirements. Each valve design has different limits. But, my seat of the pants feel is that you can do this with one valve. I have included an example. I am not specifically recommending this company. -- Regards, John Popelish

- Q: Hi My sons car has alloy wheels, and metal valve stems, there is a tiny leak between the valve stam and the alloy on one wheel, we are struggling to get anyone to repair at a reasonable cost. Would tyre weld make a permanent repair?. Some tyre specialists won't touch the wheel, one other wants to drill out the stem put in another, which sounds a bit drastic. Any other ideas?, is it feasible to get the metal valve stem replaced by a rubber version?. Apparently the metal ones get curbed and then start to leak.

- On that year car the tire is tubeless and the valve stem should not be moving as it would if you had a tube type tire. If the valve stem is pushing in it means you drove on the tire while flat and probably ruined the tire as well as the valve stem. The tire must come off the rim to be inspected before blowing it back up and used. If you don't inspect the tire it will probably blow out at highway speeds and kill someone!

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- Its heart surgery, which is riskier than many other surgeries, but valve replacement is routine procedure. There's a variety of different procedures that are used and several different types of replacement valves. Some valves can be repaired and some need to be replaced. Repairs usually give a person a normal or nearly normal valve that will last forever. Valve replacements don't work quite as wells as repairs and they usually need to be replaced in a decade or so. Most people can have the valved replaced by threading a scope through the arteries or using tiny incisions, but some people require open heart surgery. My friend had one of his valves replaced with a valve made from a pig heart and he was only in the hospital one night, and back to work a week later.

- Q: I have a 2001 Ford Ranger with a 4.0 V6. I recently broke the valve cover bolt on the top right hand corner of the passenger valve cover ( the bolt closest to the belt). 1. Can I drive it like this and since 7 of the 8 bolts are in it should it leak worse. 2. How do I fix it, and 3. How much would this cost to have fixed if I took it somewhere. Thanks for your help

- Yes you can drive the vehicle with 1 broken bolt to the valve cover. The valve cover should leak a little due to the lack of tension at the broken bolt. The leak may be minimal. If you remove the valve cover use silicone as a new gasket, you can use extra silicone at the broken bolt. Allow the silicone to dry before tightening the valve cover bolts. The extra silicone may stop any oil to blow by the broken bolt problem solved. The valve cover does nothing more than stopping oil from leaking. A leaky valve cover nothing more than leak will not affect how the vehicle runs. The cost to have the broken bolt replaced should be around $100.00 (if the broken bolt is accessible) The cost is strictly labor (time). About $100.00/an hour. To repair this you have 3 options; 1) You can extract the bolt. This may be very easy depending on the accessibility (can you get a drill over the broken bolt?). If you can drill a whole in the broken bolt, you can lightly tap an extractor into the whole with a hammer. Then with a wrench or a pipe wrench you can try to extract the bolt by turning the extractor counter clockwise. Use WD40 or a catalyst to loosen the broken bolt. The longer the catalyst (WD40) has to work the better. ie- spray the broken bolt 3 or 4 times a day allow the oil time to loosen the broken bolt. You can purchase extractors at any auto parts store for about $15.00 I can't emphasize the importance of WD40 enough!!!! 2) The 2nd option is to use a healy coil. You would need to drill out the bolt to a specific size (the healy coil package will tell you what size drill bit to use). After drilling out the bolt you can insert a healy coil that will allow you to use the same size bolt you just drilled out. The healy coil package will have detailed instructions. This is very easy to do! Healy coils can hold a lot more torque than valve covers require. 3) The third option is to drill out the broken bolt completely tap new threads insert a larger bolt.

- Q: 1. Why is there an exaust valve. Isnt it only a port. Where do the gases that go into the exaust valve go?2. How does air enter the intake valve. If you look at a push rod diagram, you cant see where the air is enteringCan someone explain to me the valve concept

- You're not dumb for trying to learn. In a 4 stroke engine the air goes into the intake manifold and into the intake ports on the head. There it interacts with the valve, which when opened allows the air to be drawn into the cylinder. Then the engine goes through the power stroke and then the exhaust is forced out through the exhaust valve.

- Q: I been playing the trombone for 6 years, do you think i could learn to play the baritone easily,which baritone is easier,3 valve or 4 valve.

- Some baritones have 3 valves, but the others have 4. The 3 valved ones are baritones and then the 4 valved ones are euphoniums.

Send your message to us

DN500 Turbine Type Butterfly Valve with Hand wheel BS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords