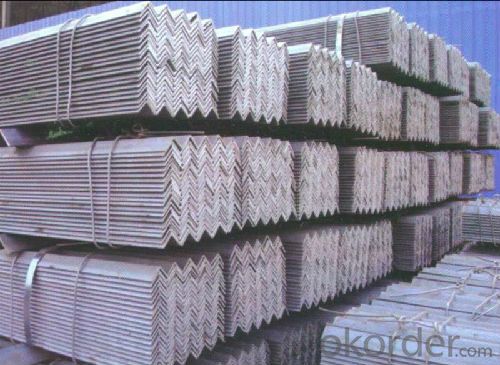

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel equal angle for construction JIS G3192at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel equal angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel equal angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricin

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

:

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

FAQ:

Q1: How do we guarantee the quality of our products?A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Can steel angles be used in fencing?

- Indeed, fencing can make use of steel angles. Steel angles find frequent application in fencing scenarios, serving to furnish structural reinforcement and stability. Their utility ranges from functioning as posts to serving as crossbars, contingent upon the particular design of the fencing. Steel angles possess robustness and durability, rendering them well-suited for enduring various elements whilst guaranteeing security. Through facile welding or bolting, steel angles can effortlessly be conjoined to construct a resilient fencing structure. Furthermore, steel angles can be galvanized or coated, augmenting their resistance to rust and corrosion, thereby securing a fencing solution that endures for a prolonged period with minimal maintenance.

- Q:Can steel angles be used for supporting mechanical equipment?

- Indeed, mechanical equipment can be effectively supported using steel angles. In construction and engineering endeavors, steel angles are frequently employed owing to their robustness, resilience, and adaptability. They furnish a steady and inflexible support framework for a wide array of mechanical equipment such as weighty machinery, conveyors, and support frames. Notably, steel angles are acclaimed for their capacity to bear weight, rendering them optimal for furnishing structural support in industrial settings. Furthermore, their L-shaped configuration facilitates effortless equipment installation and attachment. All in all, steel angles are a trustworthy and prevalent choice for bolstering mechanical equipment due to their strength, durability, and user-friendliness.

- Q:Can steel angles be used in overhead crane or hoist systems?

- Yes, steel angles can be used in overhead crane or hoist systems. They are commonly used as structural components to support and reinforce the various parts of the system, such as the crane bridge, runway beams, and trolley frames. Steel angles provide strength, stability, and durability, making them suitable for withstanding the heavy loads and dynamic forces associated with crane and hoist operations.

- Q:How do steel angles contribute to the resiliency of a structure?

- Steel angles contribute to the resiliency of a structure by providing additional strength and stability. They are commonly used in construction to reinforce corners and joints, helping to distribute loads and resist bending or twisting forces. This added structural support enhances the overall resilience of the building, making it more resistant to potential hazards such as earthquakes, high winds, or heavy loads.

- Q:What are the different types of steel angles connections for mezzanine floors?

- There are several different types of steel angle connections that can be used for mezzanine floors. These connections are designed to provide structural stability and support for the floor, ensuring that it can safely accommodate the intended loads and usage. 1. Bolted Connections: Bolted connections are commonly used in mezzanine floors as they offer a strong and secure connection. These connections involve using bolts to attach the steel angles together, creating a rigid and stable framework. Bolted connections can be easily adjusted or disassembled if required. 2. Welded Connections: Welded connections involve joining the steel angles using welding techniques. This type of connection provides a permanent and strong bond between the angles, ensuring maximum stability. Welded connections are often preferred for heavy-duty mezzanine floors where high load-bearing capacity is required. 3. Clip Connections: Clip connections are a popular choice for mezzanine floors as they offer ease of installation and flexibility. These connections involve using metal clips or brackets to secure the steel angles together. Clip connections can be easily adjusted or disassembled, allowing for future modifications or reconfigurations of the mezzanine floor layout. 4. Gusset Plate Connections: Gusset plate connections involve using additional steel plates, known as gusset plates, to reinforce the joint between the steel angles. These plates are typically welded or bolted to the angles, providing added strength and stability to the connection. Gusset plate connections are commonly used in mezzanine floors where extra reinforcement is necessary. 5. Cleat Connections: Cleat connections involve using a cleat plate to connect two steel angles. The cleat plate is attached to one angle, while the other angle is bolted or welded to the plate. This type of connection provides a strong and secure joint, particularly when used with heavy-duty mezzanine floors. It is essential to ensure that the chosen steel angle connections for mezzanine floors are in compliance with local building codes and regulations. Additionally, consulting a structural engineer or a professional with expertise in mezzanine floor construction is recommended to ensure the connections are designed and installed correctly for optimal safety and performance.

- Q:How do steel angles compare to other materials like aluminum or wood?

- Steel angles possess several advantages over materials such as aluminum or wood. Firstly, they are renowned for their strength and durability. Steel is an exceptionally robust substance capable of withstanding heavy loads and high-pressure scenarios, rendering it ideal for structural purposes. In contrast, aluminum is comparatively weaker and less durable, making it more suitable for lightweight applications. Secondly, steel angles exhibit excellent fire resistance properties. Steel is non-combustible, meaning it does not burn or contribute to fire propagation. Conversely, wood is highly flammable and can pose a fire hazard in certain circumstances. Although aluminum has a higher melting point than wood, it does not possess the same level of fire resistance as steel. Additionally, steel angles outperform both aluminum and wood in terms of corrosion resistance. Steel can be galvanized or treated with protective coatings to prevent rust and corrosion, making it suitable for outdoor or marine applications. Although aluminum has a natural oxide layer that resists corrosion, it is still more susceptible to corrosion than steel. Wood, being an organic material, is highly vulnerable to rot and decay when exposed to moisture or insects. Another advantage of steel angles lies in their versatility. Steel can be easily fabricated and manipulated into various shapes and sizes, offering a wide range of design possibilities. While aluminum also provides some flexibility in terms of fabrication, it is generally less malleable and more prone to cracking. Wood, although relatively easy to work with, has limitations in terms of structural integrity and design flexibility. Regarding cost, steel angles are typically more economical than aluminum. Steel is widely available and has lower production costs, making it a cost-effective choice for many applications. Conversely, aluminum can be more expensive due to higher production costs and its limited availability. Depending on the type and quality, wood may vary in price but is often more affordable than steel or aluminum. In summary, steel angles provide superior strength, durability, fire resistance, corrosion resistance, versatility, and cost-effectiveness compared to materials like aluminum or wood. However, the choice of material ultimately depends on the specific application, design requirements, and budget constraints.

- Q:Can steel angles be used in conveyor systems?

- Yes, steel angles can be used in conveyor systems. Steel angles are commonly used in conveyor systems to provide structural support and stability. They can be utilized to create the framework for the conveyor system, including the conveyor bed, side frames, and supports. Steel angles are known for their strength and durability, making them an ideal material for handling heavy loads and withstanding the continuous movement and impact that conveyor systems experience. Additionally, steel angles can be easily welded or bolted together, allowing for flexibility in designing and customizing conveyor systems to meet specific requirements. Overall, steel angles are a popular choice in conveyor system construction due to their reliability, versatility, and cost-effectiveness.

- Q:What are the different types of steel angles connections for columns?

- There are several different types of steel angle connections for columns, including the bolted shear plate connection, welded connection, and clip angle connection. Each type of connection has its own advantages and disadvantages, and the choice of connection depends on factors such as the load requirements, design preferences, and ease of installation.

- Q:Can steel angles be used for manufacturing bike racks?

- Yes, steel angles can be used for manufacturing bike racks. Steel angles provide strength and durability, making them suitable for supporting the weight of multiple bicycles. Additionally, steel angles can be easily welded or bolted together to create a sturdy frame for the bike rack. The versatility of steel angles allows for customization and design flexibility to accommodate different types and sizes of bicycles. Furthermore, steel angles can withstand outdoor conditions and are resistant to rust and corrosion, ensuring the longevity of the bike rack. Overall, steel angles are a reliable and practical choice for manufacturing bike racks.

- Q:Can steel angles be used in agricultural applications?

- Yes, steel angles can be used in agricultural applications. They are commonly used in the construction of buildings, fences, and equipment in the agricultural industry due to their strength, durability, and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords