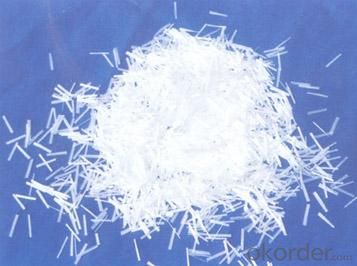

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Wet Chopped Strands are compatible with unsaturated polyester, epoxy and phenolic resins and gypsum.

Wet Chopped Strands have moderate moisture content and deliver outstanding flowability, including dispersion in water and in gypsum.

2.Product Features:

Excellent dispersion in water

Good bonding with multiple resins

Outstanding tensile and tear properties in the final product

3.Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

| (%) | (%) | (%) | (%) |

Mathods | IS01888 | ISO3344 | ISO1887 |

|

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

12mm | ||||

18mm |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:Does fiberglass chopped strand improve the chemical resistance of composite materials?

- The chemical resistance of composite materials can be enhanced through the incorporation of fiberglass chopped strand. Fiberglass possesses exceptional chemical resistance due to its inert nature and lack of reactivity with most chemicals. When utilized as a reinforcement in composite materials, particularly in fiberglass-reinforced plastics (FRPs), the chopped strand contributes to an overall improvement in chemical resistance. By reinforcing the composite matrix, the chopped strand augments its strength and durability. This reinforcement effectively impedes the infiltration and absorption of chemicals, thereby heightening the composite material's resistance to chemical attacks. Moreover, the fiberglass chopped strand can function as a protective barrier, preventing the chemicals from reaching the underlying layers of the composite and causing harm. To further enhance the chemical resistance of composite materials, it is crucial to select the appropriate type and sizing of the fiberglass chopped strand. Different types of fiberglass, such as E-glass, S-glass, and boron fibers, offer varying degrees of chemical resistance. Additionally, the application of a specific sizing or coating to the chopped strand can also bolster its chemical resistance properties. Nevertheless, it is important to acknowledge that while the incorporation of fiberglass chopped strand can enhance the chemical resistance of composite materials, it does not render them completely impervious to all types of chemicals. Certain aggressive chemicals, such as potent acids or bases, may still elicit damage to the composite, even with the presence of fiberglass chopped strand. Consequently, it is imperative to consider the precise chemical environment in which the composite will be utilized and accordingly select suitable materials and reinforcements.

- Q:What are the typical processing challenges when using fiberglass chopped strand composites?

- When using fiberglass chopped strand composites, there are several typical processing challenges that may arise. One of the main challenges is achieving consistent fiber dispersion throughout the composite material. Since chopped strand composites consist of short lengths of fiber, it can be difficult to ensure that the fibers are evenly distributed within the resin matrix. This can lead to areas of low fiber content, resulting in reduced mechanical properties and potential weaknesses in the final product. Another challenge is managing the processing temperature. Fiberglass chopped strand composites typically require higher processing temperatures compared to other materials. This can pose challenges in terms of selecting the appropriate processing equipment and ensuring that the temperature remains within the optimal range throughout the manufacturing process. Failure to control the temperature can result in poor resin flow, incomplete curing, or even degradation of the fibers. Furthermore, the abrasive nature of fiberglass can lead to increased wear and tear on processing equipment. The sharp edges of the chopped fibers can cause excessive wear on molds, dies, and other components of the production machinery. This requires regular maintenance and replacement of parts, adding to the overall cost and complexity of the manufacturing process. Additionally, the handling and storage of chopped strand composites can be challenging. The fibers are prone to breakage and entanglement, which can make it difficult to handle and feed them into the processing equipment. Proper storage conditions, such as maintaining low humidity levels, are also crucial to avoid moisture absorption by the fibers, which can negatively affect their performance and adhesion to the resin matrix. Lastly, achieving consistent and reliable bonding between the fibers and the resin matrix can be a challenge. The short lengths of the chopped fibers make it more difficult to achieve a strong bond, which can result in reduced mechanical strength and potential delamination issues in the final product. Special attention needs to be given to the resin formulation and processing parameters to ensure optimal fiber-matrix adhesion. Overall, while fiberglass chopped strand composites offer numerous advantages such as high strength-to-weight ratio and corrosion resistance, they also present several processing challenges that need to be carefully addressed to achieve high-quality and reliable end products.

- Q:Is fiberglass chopped strand suitable for construction reinforcement applications?

- Construction reinforcement applications can benefit from the use of fiberglass chopped strand. This material is created by chopping fiberglass strands into smaller pieces, usually around 1 to 3 inches in length. These chopped strands are then mixed with a binder and molded into mats or sheets. The advantages of fiberglass chopped strand make it an excellent option for construction reinforcement. Firstly, fiberglass is known for its strength and durability, which enhances the overall strength of structures. It possesses high tensile strength and exceptional resistance to chemicals, corrosion, and weathering, allowing for its use in various construction applications. What's more, fiberglass chopped strand is lightweight, making it easier to handle and install compared to traditional reinforcement materials like steel. This can result in faster construction times and reduced labor costs. Moreover, fiberglass chopped strand is non-conductive and non-magnetic, making it ideal for situations where electrical conductivity or magnetic interference must be avoided. It is also non-combustible, providing an added level of safety in construction projects. In conclusion, fiberglass chopped strand is a versatile and dependable material for construction reinforcement. Its combination of strength, durability, lightweight nature, and non-conductive properties make it suitable for a wide range of construction projects.

- Q:Can fiberglass chopped strand be used in the production of electrical circuit boards?

- No, fiberglass chopped strand is not typically used in the production of electrical circuit boards. Circuit boards are usually made from materials such as epoxy resin, copper, and various types of laminates, which provide the necessary electrical properties and reliability required for circuitry.

- Q:What is the typical diameter of fiberglass chopped strand?

- The typical diameter of fiberglass chopped strand is around 10 to 25 micrometers.

- Q:How is the tensile strength of fiberglass chopped strand determined?

- The tensile strength of fiberglass chopped strand is determined through a standardized testing method known as ASTM D2343-17. This test involves taking a sample of the fiberglass chopped strand and subjecting it to a controlled pulling force until it breaks. The force required to break the sample is then measured, and this value is used to determine the tensile strength of the fiberglass chopped strand. During the testing process, the fiberglass chopped strand is typically held in a specially designed grip system, which ensures a secure and uniform distribution of the pulling force. The grip system is attached to a universal testing machine, which has the capability to apply a steadily increasing force to the sample. The test is carried out in a controlled laboratory environment, with specific parameters such as temperature and humidity being maintained to ensure accurate and reliable results. Several samples are usually tested to ensure statistical significance. Once the test is complete, the maximum force required to break the sample is recorded. This value is then divided by the cross-sectional area of the sample to calculate the tensile strength of the fiberglass chopped strand. The tensile strength is typically reported in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa). By determining the tensile strength of fiberglass chopped strand, manufacturers and end-users can assess its suitability for various applications that require high tensile strength properties, such as in the production of composite materials, construction, automotive, aerospace, and marine industries.

- Q:What is the tensile strength of fiberglass chopped strand?

- The specific type and manufacturer of fiberglass chopped strand can cause variations in its tensile strength. Typically, though, its tensile strength falls within the range of 200 MPa to 800 MPa. This indicates its ability to withstand significant pulling force without breaking or fracturing. Other factors, including fiber length and orientation, resin binding, and manufacturing process, can also affect the actual tensile strength. To obtain precise and detailed information about the tensile strength of a specific fiberglass chopped strand product, it is advisable to consult the manufacturer's datasheet or technical specifications.

- Q:How does the fiber dispersion affect the surface finish of chopped strand composites?

- Fiber dispersion plays a crucial role in determining the surface finish of chopped strand composites. When fibers are evenly dispersed throughout the composite matrix, they provide better reinforcement and enhance the overall mechanical properties of the material. This results in a smoother and more uniform surface finish. On the other hand, poor fiber dispersion leads to uneven distribution of the fibers, causing voids, porosity, and potential defects on the surface of the composite. Thus, achieving proper fiber dispersion is essential for obtaining a high-quality surface finish in chopped strand composites.

- Q:Can fiberglass chopped strand be used in wind turbine rotor blades?

- Wind turbine rotor blades can indeed utilize fiberglass chopped strand. Given its lightweight, high strength, and resistance to corrosion, fiberglass is a popular choice in the construction of these blades. In the manufacturing process, chopped strand mat, composed of short fiberglass strands bonded together, is frequently employed. These chopped strands are arranged in a specific pattern and subsequently infused with resin to create a composite material that boasts both strength and flexibility. This composite material is then molded into the desired shape of the wind turbine blade. All in all, fiberglass chopped strand is an extensively utilized and appropriate material for the production of wind turbine rotor blades.

- Q:Is fiberglass chopped strand resistant to heat?

- Generally, fiberglass chopped strand exhibits resistance to heat. It is composed of glass fibers and a thermosetting resin, typically polyester or epoxy. These constituents possess a high melting point and can endure elevated temperatures without melting or distorting. Nevertheless, it is crucial to acknowledge that the heat resistance of fiberglass may fluctuate depending on the particular type and composition of the material. Certain fiberglass items are engineered to withstand higher temperatures compared to others. It is highly advised to consult the manufacturer's specifications and guidelines for the particular fiberglass chopped strand product to ascertain its heat resistance capabilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords