Fiberglass Geogrid Used in Dikes,Dams,Tunnels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

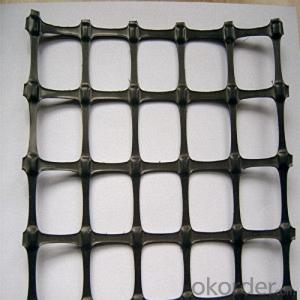

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q:How do geotextiles affect noise pollution?

- Geotextiles can help reduce noise pollution by acting as a sound barrier. They absorb and dampen sound waves, preventing them from traveling through the ground and creating noise pollution.

- Q:What are the specifications for geotextiles in athletic field construction?

- The specifications for geotextiles in athletic field construction typically include factors such as strength, permeability, and durability. Geotextiles used in this context are usually required to have high tensile strength to withstand the stresses placed upon them during installation and use. They should also have appropriate permeability to allow for proper drainage and prevent waterlogging. Additionally, geotextiles for athletic field construction should be durable and resistant to UV degradation, chemicals, and physical damage. These specifications ensure that the geotextile effectively reinforces the field, provides adequate drainage, and maintains its integrity over time.

- Q:How are geotextiles tested for durability?

- Geotextiles are tested for durability through various methods including tensile strength testing, abrasion resistance testing, and exposure to environmental conditions such as UV radiation, temperature variations, and chemical exposure. Additionally, geotextiles may undergo puncture resistance testing and hydraulic conductivity testing to assess their long-term performance and suitability for specific applications.

- Q:What are the design considerations for geotextile applications?

- Some design considerations for geotextile applications include the type and weight of the geotextile material, the strength and durability requirements, the expected level of permeability, the ability to withstand environmental conditions such as UV exposure or chemical exposure, and the compatibility with other materials used in the project. Additionally, factors such as installation methods, load distribution, and long-term maintenance should also be taken into account during the design process.

- Q:Polyester filament geotextile performance characteristics

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q:The outside of the blind tube is not to be with the geotextile 1 effect will be better?

- Plastic blind ditch is a new geosynthetics, is composed of plastic core wrapped outside the filter composition. At present the plastic core has several different cross-sectional shape rectangular, hollow rectangular, circular and hollow circular species structure of the plastic blind ditch products. Pass the water to see the original tie & gt; & gt;

- Q:What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the raw materials used, the manufacturing process employed, the thickness and density of the geotextile, and the presence of any additives or coatings. Additionally, environmental factors such as temperature, moisture, and exposure to UV radiation can also influence the tensile strength of geotextiles.

- Q:What are the different geotextile installation techniques in slope stabilization?

- There are several geotextile installation techniques used in slope stabilization, including slope face treatment, wrap-around technique, and anchor trenching. In slope face treatment, geotextiles are placed directly on the slope surface to prevent erosion and promote vegetation growth. The wrap-around technique involves installing geotextiles horizontally around the slope, creating a reinforced barrier against soil movement. Anchor trenching, on the other hand, involves burying geotextiles vertically into the slope to provide added stability and resistance against sliding. These techniques are commonly used in combination to ensure effective slope stabilization.

- Q:Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles are commonly used in these facilities to provide erosion control, filtration, and separation of different waste materials. They help to enhance the stability and performance of the storage facility by preventing soil erosion and promoting proper drainage. Additionally, geotextiles can also be used to cover and contain waste materials, preventing any potential contamination or leaching into the surrounding environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Used in Dikes,Dams,Tunnels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords