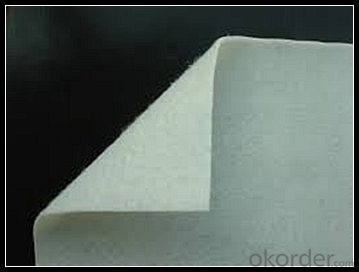

500g Nonwoven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Color:

White, Black, etc

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

Nonwoven Geotextile

Geosynthetics are described or characterized as civil engineering materials that are intended for use with geological components like so rock or any other civil engineering associated materials to enhance or transform its behaviour, bringing out revolutions advantages in abundant area. They are porous textile materials of Non woven, woven or knitted. Their rise development for the period of the last 15 years has been nothing short of overwhelming and remarkable.Geosynthetics are up to date and modern construction products that can be utilized in transportation (rural roads, national state highways, seaports, airports).

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the factors to consider when designing geotextile-reinforced pavements?

- When designing geotextile-reinforced pavements, several factors need to be considered. Firstly, the type and characteristics of the geotextile, such as its tensile strength, permeability, and durability, are crucial for ensuring its effectiveness in reinforcing the pavement. Secondly, the properties of the soil and subgrade, including their bearing capacity, moisture content, and stability, must be taken into account to determine the appropriate geotextile design. Additionally, the traffic load and volume, as well as the climate conditions of the project area, play a significant role in selecting the suitable geotextile and pavement thickness. Proper installation techniques, quality control measures, and regular maintenance should also be considered to ensure the long-term performance of geotextile-reinforced pavements.

- Q:Can geotextiles be used in riverbank stabilization applications?

- Yes, geotextiles can be used in riverbank stabilization applications. They are commonly used to prevent erosion and promote soil stability along riverbanks. Geotextiles have the ability to filter water while allowing for proper drainage, which helps to prevent soil erosion and maintain the integrity of riverbanks. They can be installed as a protective barrier and provide reinforcement to the soil, making them an effective solution for riverbank stabilization.

- Q:How are geotextiles different from other types of geosynthetics?

- Geotextiles are a type of geosynthetic that are specifically designed to provide filtration, separation, and reinforcement functions in civil engineering applications. Unlike other types of geosynthetics such as geogrids or geomembranes, geotextiles are typically made from non-woven or woven fabrics, allowing them to have a higher permeability and flexibility. Geotextiles are primarily used to control soil erosion, improve drainage, and provide stability in various construction projects.

- Q:How do geotextiles aid in the reduction of lateral spreading?

- Geotextiles aid in the reduction of lateral spreading by providing a barrier against soil movement and erosion. They are placed horizontally between layers of soil, acting as a stabilizing agent by distributing the lateral forces and restricting the movement of soil particles. This helps to prevent the lateral spreading of soil and enhances the overall stability of slopes, embankments, and other geotechnical structures.

- Q:400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q:Geotextile is what kind of material in the construction? Is it a hydroelectric material?

- Is not geosynthetics, also known as "geotextile", "geotextile", it is synthetic fiber, plastic, synthetic rubber as raw materials made of different kinds of products, the use of the process of separation, reinforcement, drainage, filtration, , Seepage six basic functions. Abroad in the thirties began to use, so far its products from a single textile development to other synthetic materials and composite materials. Now geosynthetics has been called with steel, cement, wood par, "the fourth engineering materials", and widely used in geotechnical, water and civil engineering and other fields.

- Q:How do geotextiles help in preventing the growth of weeds?

- Geotextiles help in preventing the growth of weeds by acting as a physical barrier between the soil and the environment. These permeable fabrics are designed to allow water and air to pass through but inhibit the growth of weeds by blocking sunlight, which is essential for weed germination and growth. Additionally, geotextiles can also prevent weed seeds from reaching the soil, thus minimizing the potential for weed growth.

- Q:Green belt with no cloth a film seepage geotextile cloth how

- The water will be missed, the general green belt does not require the use of two cloth a film, according to design requirements it

- Q:What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as the material type, weight, permeability, and strength. They should be made of durable materials that can withstand environmental conditions and retain sediment effectively. The weight of the geotextile is usually specified to ensure proper retention of sediment particles. Permeability is an important factor as it allows water to pass through while retaining sediment. Lastly, the strength of the geotextile should be sufficient to withstand installation and potential stress from soil erosion.

- Q:What are the advantages of using geotextiles?

- Geotextiles offer several advantages such as soil stabilization, erosion control, filtration, and drainage, which can enhance the overall performance and longevity of civil engineering projects. They provide a cost-effective solution by reducing the need for extensive excavation, improving load-bearing capacity, and minimizing long-term maintenance requirements. Additionally, geotextiles are environmentally friendly, allowing water and air circulation while preventing soil erosion, thereby promoting sustainable development and conservation of natural resources.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

500g Nonwoven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords