Short Non-woven Geotextile PP&PET Non-woven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Introduction

1:Use of polyester staple fiber nonwoven fabric with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) in isolation. Make no loss between two or more materials, not mixed, maintains the whole structure and function of material, to reinforce structure load bearing capacity.

2: Filter

When water flows into coarse material composed of fine soil soil layer, the use of polyester staple fiber geotextile acupuncture good air permeability and water permeability, make the water flow through, and effectively current-carrying soil particles, sand, small stones, etc., to maintain the stability of soil and water conservation project.

Product Features

Can self-seal small cracks while forming watertight laps at the seams.

Provides a strong mechanical bond to poured concrete.

Proven effective in structures under continuous or intermittent hydrostatic pressure-up to 70m (231 ft).

Can be installed in virtually any weather condition, including freezing temperatures and damp conditions. Can be installed on green concrete without primers or adhesives.

Proven effective in both vertical and horizontal applications-i.e., backfilled and property-line walls.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

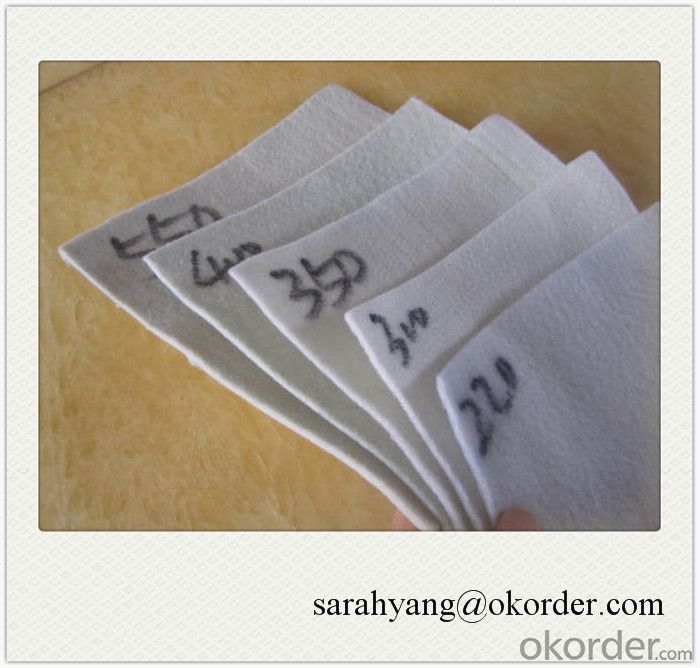

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q:How do geotextiles contribute to the sustainability of construction projects?

- Geotextiles contribute to the sustainability of construction projects in several ways. Firstly, they can be used as a substitute for traditional materials, such as gravel or sand, which reduces the demand for natural resources and minimizes environmental impact. Secondly, geotextiles improve soil stability and prevent erosion, ensuring the longevity of structures and reducing the need for costly repairs or replacements. Additionally, these textiles can enhance the efficiency of drainage systems, leading to reduced water consumption and improved water quality. Overall, geotextiles promote sustainable construction practices by conserving resources, enhancing durability, and minimizing environmental degradation.

- Q:Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q:How do geotextiles contribute to soil remediation?

- Geotextiles contribute to soil remediation by providing a physical barrier that separates contaminated soil from clean soil, preventing the spread of pollutants. They also promote drainage, filtration, and stabilization of the soil, enhancing the effectiveness of remediation techniques such as soil washing, bioremediation, and phytoremediation.

- Q:How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through various methods such as tensile strength testing, puncture resistance testing, water permeability testing, and UV resistance testing. These tests ensure that geotextiles meet the required standards and can perform effectively in their intended applications.

- Q:How are geotextiles used in geotechnical engineering?

- Geotextiles are used in geotechnical engineering to enhance soil stability, drainage, filtration, and erosion control. They are commonly used as reinforcement layers in road construction, embankments, retaining walls, and landfills. Geotextiles improve the overall performance and longevity of geotechnical structures by providing separation, filtration, and reinforcement functions.

- Q:Water stability grassroots health permeable geotextile or plastic film is good?

- To achieve the desired health, filter the effect of water, must be geotextile, only to cope, it can only be plastic film friends

- Q:Performance index of composite geotextile

- Item Unit Area Quality g / m000 Remark Film Thickness mm0.25-0.350.3-0.5 Fracture strength KN / m57.510.012.014.016.018.0 Longitudinal transverse elongation% 30-100CBR Breaking strength KN≥1.11.51.92. 22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q:What are the design considerations for geotextile-reinforced soil walls?

- Some of the key design considerations for geotextile-reinforced soil walls include the selection and placement of appropriate geotextile materials, determining the required strength and stability of the wall, considering the potential for water drainage and filtration, accounting for settlement and creep behavior, evaluating the impact of external loads and surcharges, and ensuring proper construction techniques are followed. Additionally, considerations for long-term durability, environmental factors, and aesthetic aspects may also be taken into account depending on the specific project requirements.

- Q:Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. Geotextiles are commonly employed to improve the stability and performance of reservoir linings by providing reinforcement, filtration, and separation functions. They can effectively prevent soil erosion, control seepage, and enhance the overall integrity and longevity of the reservoir lining system.

- Q:What are the factors to consider when designing geotextile-reinforced structures?

- When designing geotextile-reinforced structures, several factors need to be considered. These include the type and properties of the geotextile material, the intended function and loading conditions of the structure, the site conditions and soil properties, the compatibility between the geotextile and other materials used in the construction, and the long-term durability and maintenance requirements of the structure. Additionally, factors such as construction techniques, cost-effectiveness, and environmental considerations should also be taken into account during the design process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Short Non-woven Geotextile PP&PET Non-woven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords