Bentonite Organic Type B38

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

Advantage Easy-to-Use,

Overall-Persistent Making Efficienty for Rheology,

Complete Spread in the condition of middle cutt

| Product Name | Organic Bentonite |

| Model Number | B38 |

| Description | As an improved assistant material of anti settling and thickening, our new organic |

| bentonite B38 was mainly applied for semi-polarity or high-polarity system, with a good | |

| efficiency of thixotropy, and anti settling.It saves cost as replacement of most traditional | |

| domestic and imported bentonite. | |

| Application | Nitrolacquer, Epoxy Resin Paint, Polyester Paint, Vinyl Ester Resin Paint, Polyester |

| Varnish, Marine Paint, Heavy Anti-Corrosive Paint, Chlorinted Rubber, Polyacrylic Acid | |

| Paint, Bituminous Paint, Base Paint, Adhesive, Printing Ink, Sealing Compound etc.. | |

| Dosage | The dosage of organic bentonite depends on the thickening level of requirement, the |

| control of sag resistance and anti-settling result for pigment etc. Normal dosage is | |

| 0.2%-3.0%, the dosage is better to be same as replacement when do the replacement, | |

| then adjust accroding to the specific requirement,normally less than traditional one. | |

| Advantage | Easy-to-Use, Overall-Persistent Making Efficienty for Rheology, Complete Spread in the |

| condition of middle cutting, Simplifying Viscosity & Adjustment after sag resistance, | |

| Good Stability of Heating, Good Stability of Storage. | |

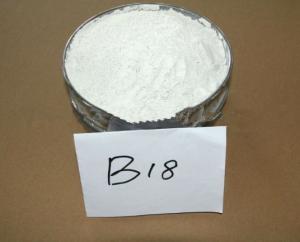

| Physical Property | Composition - Organic Montmorillonite Ramification |

| Appearance - Super Fine Powder | |

| Diameter of Grain under Complete Spread - 1-3um | |

| Colour - Parchment (Cream) | |

| Density (g/cm3) - 1.7 | |

| Mositure Level (%) - less 3.5 | |

| Burning Disappearing (%) - less 36 |

- Q: Some problems in preparation of bentonite mud and application of mud

- In the production of mud soil, in order to improve the slurry rate and viscosity, blind adding polymer - - will cause pulp difficult, water and soil stratification. Several factories in Tongling will produce drilling mud soil and engineering mud soil. First of all, be modest and don't play smart. Then go out, learn from other people's experiences and combine your own facts to produce the right mud.

- Q: What is the main ingredient of bentonite?

- The bentonite is non metallic mineral montmorillonite as the main mineral composition, structure of montmorillonite is 2:1 type crystal structure of [1] consists of two silicon oxygen tetrahedron sandwiching a layer of aluminum eight surface body composition, due to the layered structure of montmorillonite crystal cell formation in the presence of some cations, such as Cu, Mg, Na, K, and the cation with montmorillonite crystal cell function is not strong, easy to by other cation exchange, so it has good ion exchange property. Foreign countries have been applied in more than 100 sectors of industry, agriculture and production in 24 fields, and there are more than 300 products, so people call it "omnipotent soil"".

- Q: What is the density of bentonite, that is, how heavy is one?

- Some properties of bentonite are also determined by montmorillonite. The density is 2~3g/cm3. Montmorillonite can be a variety of colors, such as yellow green, yellow white, gray, white and so on. Can be dense, massive, or for loose soil, with fingers rubbed when there is a sense of sliding, small pieces of water after the volume of swelling several times to 20-30 times, in the water as a suspended shape, less water when it was mushy.

- Q: How much is the amount of blue absorbed by bentonite?

- Bentonite (Meng Tuoshi) has the ability to adsorb methylene blue.

- Q: What is the maximum amount of alkali added to the casting bentonite?

- Calcium based bentonite is modified by sodium to improve its thermal, wet, tensile strength, permeability and reusability.

- Q: Litter used flower fertilizer can do?

- The cat litter is feeding the cat owners to bury the feces and urine of the object, has good water absorption, usually with a litter box (or cat toilet) used together, the amount of litter fall in the litter box, trained when the cat will need to drain into the litter box in the drain in the above.

- Q: How often does bentonite add alkali?

- Displacement or intercalation can not be separated from moisture; the temperature is suitable to shorten the reaction time; shear and extrusion promote bond breaking and intercalation.

- Q: Difference between composite geomembrane and bentonite waterproof blanket

- Waterproof performance is different. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth, one membrane and two cloth membrane. Tensile, anti tear, bursting and other physical and mechanical properties of high indicators, products with high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good anti-seepage performance and so on.

- Q: What is bentonite? What's the difference between good and bad?

- And a lot of iron will affect its quality, selection is very important.

- Q: Does bentonite have water separation and oiliness?

- No, only bentonite is now available.Bentonite can be divided into sodium based bentonite (alkaline soil), calcium based bentonite (alkaline earth soil), natural bleaching soil (acid soil or acid clay), including calcium based bentonite, including calcium, sodium and calcium magnesium based.

We focus on developing and utilizing bentonite products at high grade. Based on the traditional bentonite clay, we have developed many new and classic organic bentonite products for multiple fields, such as painting, coating, ink, waterproof, drilling, etc.

Our organic bentonite is mainly used in industrial fields, and is used for adding system adhesive, protecting sedimentation and controlling liquid sagging.

We are looking forward to achieving good cooperation with partners at home and abroad and creating a glorious future.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,NingBo |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Bentonite Organic Type B38

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords