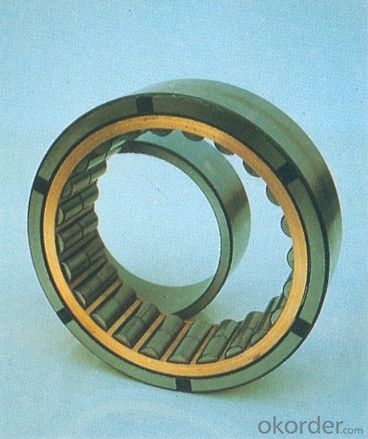

Bearings four row cylindrical roller FC202970

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

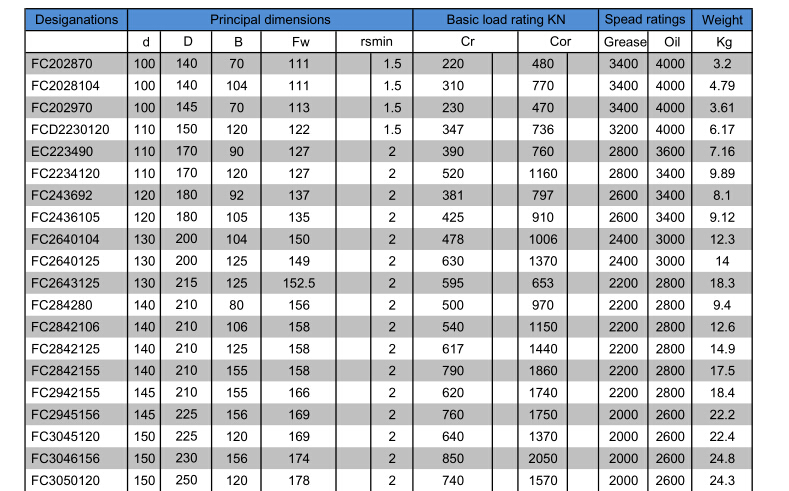

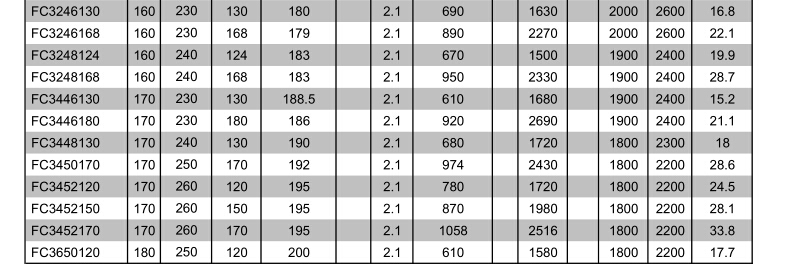

Four Cylindrical Roller Bearings Catalugue

- Q: What are the differences between cylindrical roller bearings nu208m and nu208em?

- E means "reinforced", "rolling", "thickening", "change", "change".. Hope to adopt!!

- Q: what does that mean? Please enlighten master, thank you.

- Cylindrical roller bearingN216E stands for the bearing retainer as a steel cageN216EM stands for the bearing holder as brass holderThe material of the cage is different (the structure that holds the roller in it for a long time)

- Q: In the car there is a cylindrical roller, the size of the diameter of 25mm, the outer diameter of 32mm, width of 9.5mm, who knows what the standard size, have direct purchase Mody, thank you!

- There is some doubt about your description. According to your internal diameter and external diameter, if the cylindrical roller bearings, the scroll is quite small. I don't see much of this kind of cylindrical roller bearing. Do you mean needle roller bearings? If needle roller bearings can be found, and HK2514/18 RS similar models.

- Q: Can you make it clear? I don't understand. Thank you for being here first.

- The rollers refer to the rolling bodies as cylinders and similar cylindrical shapes, such as short columns, long columns, tapered rollers, spherical rollers, etc..

- Q: Cylindrical roller bearings NUP2311E mounting dimensions: Da (max): 69Da (min): 64DB (min): 72DC (min): 80Da (max): 111What are the specific meanings of these dimensions? Thank you, master

- Da means shoulder diameter, that is to say, the maximum shoulder size is 69mm, and the minimum is 64mm

- Q: Why cylindrical roller bearings can not bear axial load?.

- The thrust bearing retainer plate and two pieces of circular hole of the ball and the ball hole and shaft wear in the park, circular plate, steel ball track between two plate, shaft and the bearing seat of the top plate in the round two sides, in addition to the track groove, it is not binding the radial direction, so it cannot withstand the radial load.The radial bearing by the size of the two steel ring, steel ball size between steel ring, steel ring diameter fixed by a bearing seat, shaft mounted on a small steel ring, binding only in the radial direction and axial direction of the load is not binding, so it cannot withstand the axial diameter.

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- I carefully read your question, I think the following talk about my views, this system from the point of view of the design, are questionable, at least the following several aspects of the design problem, put forward for reference only:1, the system does not have [oil seal], can only say that the design of the beginning of the consideration is somewhat lacking.2, [] general should choose roller bearing oil bath lubrication [], [] instead of grease, because the roller in the roller bearing [] [] in the grease, the grease has a strong crowding out of [], which leads to bad lubrication.3, [] grease generally rely on the mechanism of working temperature Shenglai improve grease liquidity, but need to have [] to seal and prevent the overflow of grease, no seal mechanism design [] summary, this place is only [] However, boundary lubrication, boundary lubrication [] [generally used for oil lubrication], [grease] rather than

- Q: The Russian bearing suffix No. ZST is a cylindrical roller bearing

- Well, you have to write out the whole model. The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

- Q: Why are there no double row cylindrical roller bearings in the mechanical design manual?

- Normally, the inner diameter of the bearing should be in interference fit with the shaft (for some light loads, too, with a transition fit).

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearings four row cylindrical roller FC202970

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords