ASTM -A36 Hot Rolled H-Section Steel Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

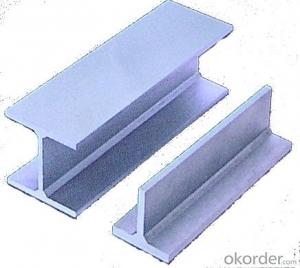

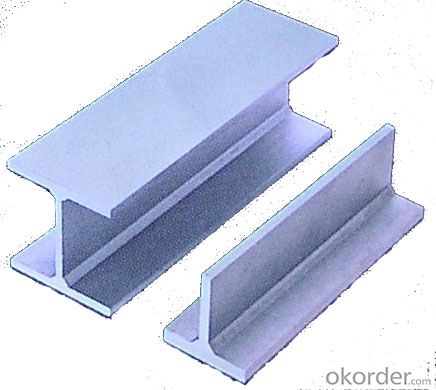

ASTM -A36 Hot Rolled H-Section Steel Column

Quick Details

Place of Origin: | China (Mainland) | Grade: | ASTM -A36 | Technique: | Hot Rolled |

Thickness: | 4mm - 16mm | Application: | decoration,kitchen,building,medical treatment,transport,chemical indus | Length: | 12 m |

Standard: | GB JIS | Flange Width: | 100--500mm | Flange Thickness: | 8--70mm |

Web Width: | 100--1000mm | Web Thickness: | 5--40mm | ||

Model Number: | H section steel ASTM -A36 | Exported Area | USA,Europe,Asia,Middle East,Africa,South America |

Application

decoration,kitchen,building,medical treatment,transport,chemical indus

Specifications

We are professional supplier and exporter of H beam.

Size:100*50*5*7mm - 700*300*13*24mm

Specification

Model Table in mm

100×50×5×7 | 200×204×12×12 | 338×351×13×13 | 482×300×11×15 |

100×100×6×8 | 244×175×7×11 | 340×250×9×14 | 488×300×11×18 |

125×60×6×8 | 244×252×11×11 | 350×175×7×11 | 496×199×9×14 |

125×125×6.5×9 | 248×124×5×8 | 350×350×12×19 | 500×200×10×16 |

148×100×6×9 | 250×125×6×9 | 360×250×12×19 | 582×300×12×17 |

150×75×5×7 | 250×250×9×14 | 360×350×12×19 | 588×300×12×20 |

150×100×6×9 | 250×255×14×14 | 390×300×10×16 | 594×302×12×20 |

150×150×7×10 | 294×200×8×12 | 396×199×7×11 | 600×200×11×17 |

175×90×5×8 | 294×302×12×12 | 400×200×8×13 | 600×300×12×20 |

175×175×7.5×11 | 298×201×9×14 | 400×400×13×21 | 700×300×13×24 |

194×150×6×9 | 300×150×6.5×9 | 414×405×18×28 | 800×300×14×26 |

200×100×5.5×8 | 300×200×8×12 | 440×300×11×18 | 900×500×16×28 |

200×150×6×9 | 300×300×10×15 | 450×200×9×14 | |

200×200×8×12 | 300×305×15×15 | 450×300×11×18 |

Pictures

- Q: How do steel H-beams contribute to daylighting in buildings?

- The inclusion of steel H-beams is crucial in enabling daylighting within buildings as they offer structural reinforcement while also facilitating the use of larger, more expansive windows. Daylighting involves utilizing natural light to brighten the interior spaces of a structure, thus diminishing the dependence on artificial lighting and fostering a more sustainable and pleasant environment. Steel H-beams possess a robust load-bearing capacity, making it feasible for them to span considerable distances and bear heavy loads, thereby allowing for the incorporation of larger window openings. These windows can be strategically positioned on exterior walls or even within the roof, granting the entry of abundant natural light into the building's interior. The utilization of steel H-beams in construction additionally confers architects with the ability to create buildings featuring open floor plans and soaring ceilings. This architectural freedom permits the incorporation of atriums, skylights, and other light wells that augment the penetration of daylight. Furthermore, steel H-beams exhibit remarkable durability and resistance to deformation, thereby ensuring the preservation of the structural integrity of the building while simultaneously maximizing the ingress of natural light. This characteristic is particularly crucial for regions prone to earthquakes or high winds. Apart from their structural advantages, steel H-beams are also highly versatile in terms of design and aesthetics. They can be seamlessly integrated into various architectural styles, thus allowing for the realization of innovative and visually appealing building designs that prioritize daylighting. Overall, the inclusion of steel H-beams significantly contributes to the achievement of daylighting within buildings by providing the essential strength and support for larger windows, facilitating the creation of imaginative architectural designs, and guaranteeing the longevity of the structure. By harnessing natural light, buildings can diminish energy consumption, enhance the well-being of occupants, and establish more sustainable and inviting spaces.

- Q: How do steel H-beams perform in areas with high humidity and chemical exposure?

- Steel H-beams generally perform well in areas with high humidity and chemical exposure due to their inherent corrosion resistance. The steel used in H-beams is often coated with protective layers or galvanized to further enhance its resistance to rust and corrosion. However, it is important to consider the specific type of chemical exposure and the severity of humidity in the area, as certain aggressive chemicals or extremely humid conditions may still affect the beams over time. Regular maintenance and inspections are recommended to ensure the long-term performance of steel H-beams in such environments.

- Q: Can steel H-beams be used for supporting mining infrastructure?

- Steel H-beams prove to be a valuable solution for supporting mining infrastructure. Their strength and versatility make them a common choice in construction and civil engineering projects. These beams are specifically designed to withstand heavy loads and provide structural support, which makes them highly suitable for mining infrastructure. In the mining industry, the stability and safety of underground tunnels, shafts, and other mining structures are of utmost importance. This requires robust support systems. Steel H-beams are well-suited for this purpose as they possess a high load-bearing capacity and resistance to bending. These qualities enable them to endure the challenging conditions commonly found in mining environments. Moreover, steel H-beams offer customization options to cater to specific project requirements. They can be easily cut into various lengths and welded together to create larger structural elements. This enables the construction of complex support systems tailored to the unique needs of mining infrastructure. Furthermore, steel H-beams are known for their durability and long lifespan. This reduces the frequency of maintenance or replacement, which is significant in the mining industry. Minimizing downtime and maintenance costs is crucial to maintain productivity and profitability. In conclusion, steel H-beams are an excellent choice for supporting mining infrastructure due to their strength, versatility, and durability. Their ability to provide the necessary support and stability in mining environments makes them an ideal option for constructing and reinforcing underground mining structures.

- Q: 300 * 150 * 6.5 * 9 H steel is used as steel beam, span 6 meters, spacing 2 meters, laying steel plate, 15 cm soil

- Q235 hot rolled H steel 300 x 150 x 6.5 x 9, weight per meter of 0.373KN. Wx=490000mm fand. Section modulus flexural strength design value of 215N/mm -. Uniform basic combination of load value Q, span 6m, the maximum bending moment design value of M=490000 * 215 =105350000N - M 105.35KN - m, q=105.35 * 8/6 L = 23.41KN/m.

- Q: What are the advantages of using steel H-beams?

- There are several advantages to using steel H-beams. First, they provide excellent structural support and load-bearing capacity, making them ideal for constructing large and heavy structures like bridges, buildings, and industrial facilities. Second, steel H-beams are highly durable and resistant to bending, warping, and corrosion, ensuring long-term stability and reliability. Additionally, they are versatile and can be easily fabricated and customized to meet specific project requirements. Finally, steel H-beams are cost-effective as they offer a high strength-to-weight ratio, reducing the amount of material needed for construction while still maintaining structural integrity.

- Q: Can steel H-beams be used in architectural applications?

- Yes, steel H-beams can be used in architectural applications. H-beams are commonly used in construction and engineering projects due to their strength, durability, and versatility. In architectural applications, H-beams can be used to create structural frameworks for buildings, bridges, and other structures. They can provide support and stability, allowing for larger open spaces and flexible design options. Additionally, H-beams can be used for aesthetic purposes, adding an industrial or modern look to architectural designs. With proper engineering and design considerations, steel H-beams can be successfully incorporated into various architectural applications.

- Q: How do steel H-beams perform in mining and industrial facilities?

- Steel H-beams are widely used in mining and industrial facilities due to their exceptional performance and durability. These beams possess several key qualities that make them a preferred choice in these settings. Firstly, steel H-beams offer great structural strength and load-bearing capacity. They are designed to withstand heavy loads and provide a high level of stability, making them suitable for supporting large structures and equipment commonly found in mining and industrial environments. Moreover, steel H-beams have excellent resistance to corrosion and can withstand harsh conditions such as high humidity, extreme temperatures, and exposure to various chemicals. This resistance to corrosion ensures the longevity and reliability of the beams, reducing the need for frequent maintenance or replacement. Another advantage of steel H-beams is their versatility. They can be easily fabricated and customized to meet specific project requirements. This flexibility allows for seamless integration into different mining and industrial applications, such as supporting conveyor belts, constructing platforms, or creating structural frameworks. Additionally, steel H-beams provide enhanced fire resistance compared to other construction materials. In the event of a fire, these beams maintain their structural integrity for a longer period, allowing more time for evacuation and minimizing the risk of collapse. Furthermore, steel H-beams have a high recyclability rate, making them an environmentally friendly choice. At the end of their lifespan, these beams can be easily recycled and reused in other applications, reducing waste and promoting sustainability. In summary, steel H-beams are highly suitable for mining and industrial facilities due to their exceptional strength, durability, corrosion resistance, versatility, fire resistance, and recyclability. Their performance in these environments ensures the safety, stability, and longevity of structures and equipment, making them a preferred choice for various applications in these industries.

- Q: Can steel H-beams be used for rooftop structures?

- Yes, steel H-beams can be used for rooftop structures. Steel H-beams are commonly used in construction due to their high strength-to-weight ratio, making them ideal for supporting heavy loads. They are often used for structural purposes in buildings, bridges, and other infrastructure projects. When it comes to rooftop structures, steel H-beams can provide the necessary support and stability required to withstand the weight of the roof, as well as any additional loads such as snow or equipment. Additionally, steel H-beams can be easily fabricated and installed, allowing for efficient construction of rooftop structures. Overall, steel H-beams are a reliable and effective choice for rooftop structures due to their strength, durability, and versatility.

- Q: What are the different types of connections used for steel H-beams to steel columns?

- There are several types of connections commonly used for steel H-beams to steel columns, including bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts to secure the beam to the column, while welded connections involve fusing the beam and column together using welding techniques. Hybrid connections combine both bolting and welding methods to provide added strength and stability. The choice of connection type depends on factors such as the load requirements, structural design, and construction preferences.

- Q: How do steel H-beams perform in coastal or saltwater environments?

- Steel H-beams perform well in coastal or saltwater environments due to their inherent corrosion resistance. The steel used in H-beams is typically galvanized or coated with protective coatings, which helps prevent corrosion caused by saltwater exposure. This makes them highly durable and suitable for withstanding the harsh conditions found in coastal areas.

Send your message to us

ASTM -A36 Hot Rolled H-Section Steel Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords