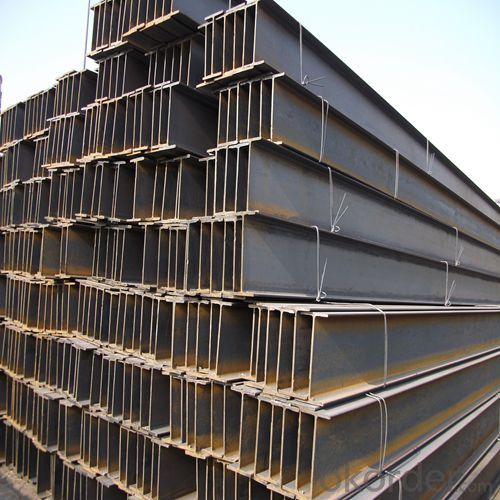

H-Beam Hot Rolled Steel Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering H-Beam Hot Rolled Steel Structure Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

H-Beam Hot Rolled Steel Structure Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's H-Beam Hot Rolled Steel Structure Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel H-beams compare to timber or concrete beams?

- Steel H-beams have several advantages over timber or concrete beams. Firstly, steel H-beams are much stronger and more durable than timber or concrete beams. Steel has a higher strength-to-weight ratio, meaning that it can support heavier loads while being lighter in weight. This allows for longer spans and larger open spaces in construction. In contrast, timber beams are prone to warping, rotting, or insect damage, while concrete beams may crack or deteriorate over time. Secondly, steel H-beams are more resistant to fire and other extreme conditions. Steel has a high melting point and does not burn, making it a safer choice in case of fire accidents. Timber beams, on the other hand, are highly flammable and can contribute to the rapid spread of fire. Concrete beams may also crack and fail under extreme heat or cold conditions. Furthermore, steel H-beams offer better flexibility and versatility in design. They can be easily fabricated into various shapes, sizes, and lengths to meet specific project requirements. Steel beams also have consistent dimensions, allowing for easier and faster installation. In contrast, timber beams are limited in terms of available sizes and may require additional processing. Concrete beams are typically cast on-site, which can be time-consuming and labor-intensive. Lastly, steel H-beams have a longer lifespan and require less maintenance compared to timber or concrete beams. Steel is resistant to corrosion, rot, and decay, making it a more durable and cost-effective choice in the long run. Timber beams need regular inspections, treatments, and replacements to maintain their structural integrity. Concrete beams may develop cracks or require repairs over time. In summary, steel H-beams offer superior strength, durability, fire resistance, design versatility, and low maintenance compared to timber or concrete beams. These advantages make steel H-beams a preferred choice in many construction projects, especially those with higher load-bearing requirements or in locations prone to extreme conditions.

- Q: How do you calculate the shear stress in steel H-beams?

- To determine the shear stress in steel H-beams, one must ascertain the applied load and the cross-sectional area of the beam. The shear stress can then be calculated by dividing the applied load by the cross-sectional area. Initially, the cross-sectional area of the H-beam must be calculated. This can be accomplished by measuring the beam's dimensions, such as the flange width, flange thickness, web height, and web thickness. Subsequently, one can calculate the area of each component (flanges and web) and then add them together to obtain the total cross-sectional area. Subsequently, the applied load on the beam needs to be determined. This information can be obtained from the design specifications or the actual load imposed on the beam. Once the value of the applied load is known, it can be divided by the cross-sectional area of the beam to calculate the shear stress. It is important to note that shear stress is typically calculated under the assumption that the load is evenly distributed across the cross-section of the beam. If the load is not uniformly distributed or if additional factors such as bending moments are present, a more comprehensive analysis may be required. In conclusion, the calculation of shear stress in steel H-beams necessitates the determination of the cross-sectional area and the division of the applied load by this area. This calculation provides insights into the shear stress experienced by the beam and aids in the evaluation of its structural integrity.

- Q: Can steel H-beams be used in historical building restoration?

- Yes, steel H-beams can be used in historical building restoration. They offer structural strength and stability, making them suitable for reinforcing or replacing damaged or weakened elements in historical buildings. However, their use should be carefully considered to ensure they maintain the historical integrity and aesthetics of the building. Proper consultation with architects, engineers, and preservation specialists is recommended to ensure the appropriate balance between preservation and structural requirements.

- Q: What are the different fire protection methods for steel H-beams?

- To ensure the structural integrity of steel H-beams and prevent collapse in the event of a fire, various fire protection methods are available. These methods comprise: 1. Utilizing Intumescent Coatings: Applying intumescent coatings onto the steel beams' surface is one effective approach. These coatings expand and create a thick insulating char layer when exposed to high temperatures. This layer safeguards the steel from heat and slows down the temperature rise. 2. Employing Cementitious Coatings: Cementitious coatings are a commonly used fire protection method for steel structures. These coatings consist of a mixture of cement, aggregates, and fibers. They act as a barrier against heat transfer and possess the ability to withstand high temperatures. 3. Utilizing Fireproofing Sprays: Fireproofing sprays offer a cost-effective means of protecting steel beams. These sprays typically contain a combination of fire-resistant materials and are applied as a thick layer onto the beams. The spray forms an insulating barrier, delaying the transfer of heat to the steel. 4. Encasing with Concrete: Another method involves encasing the steel H-beams in concrete. This method provides excellent fire protection due to concrete's high fire resistance. The concrete acts as a thermal barrier, preventing the steel from reaching critical temperatures. 5. Applying Gypsum Board Encasement: Gypsum board encasement entails covering the steel beams with multiple layers of fire-resistant gypsum board. This method provides a protective covering for the steel and is commonly used in buildings where aesthetics are a priority. It is worth noting that the selection of a fire protection method depends on factors such as fire rating requirements, architectural design, and budgetary considerations. Consulting with fire protection experts and adhering to local building codes and regulations are crucial steps to ensure the appropriate fire protection method is chosen for steel H-beams.

- Q: How do steel H-beams contribute to energy-efficient building designs?

- Steel H-beams play a crucial role in energy-efficient building designs due to their numerous benefits. Firstly, H-beams are known for their high strength-to-weight ratio, meaning they can support heavy loads while minimizing the amount of steel required. This, in turn, reduces the overall weight of the building's structure and foundation, resulting in energy savings during construction, transportation, and installation. Additionally, H-beams offer excellent structural integrity, ensuring the stability and durability of the building. Their ability to resist bending and twisting forces allows for the construction of taller and wider spaces without the need for excessive support columns or walls. The open web design of H-beams also facilitates the installation of insulation materials, enhancing the building's thermal efficiency and reducing energy consumption for heating and cooling. Furthermore, H-beams can be easily fabricated and customized to fit specific architectural designs, enabling architects to optimize the building's layout for natural lighting and ventilation. By incorporating large windows, skylights, and open spaces, energy-efficient buildings can maximize natural daylight, reducing the need for artificial lighting during the day. Similarly, proper ventilation systems can be integrated, utilizing natural airflows to cool the building and decrease the reliance on energy-intensive air conditioning. Moreover, steel H-beams possess excellent fire resistance properties, which is critical for energy-efficient buildings. Their ability to withstand high temperatures and prevent the spread of fire enhances the safety of occupants and reduces the risk of structural damage. Consequently, the need for fireproofing measures, such as additional insulation or sprinkler systems, can be minimized, saving energy and resources in the long run. In summary, steel H-beams contribute significantly to energy-efficient building designs through their high strength-to-weight ratio, structural integrity, thermal efficiency, versatility in design, and fire resistance. By utilizing these beams, architects and builders can create sustainable and environmentally-friendly structures that promote energy conservation, reduce greenhouse gas emissions, and contribute to a more sustainable future.

- Q: Can steel H-beams be used in earthquake-prone areas?

- Yes, steel H-beams can be used in earthquake-prone areas. Steel is a strong and durable material that is widely used in construction, especially in areas prone to seismic activity. H-beams, also known as I-beams, are commonly used in structural steel construction due to their high strength-to-weight ratio and ability to withstand heavy loads. In earthquake-prone areas, buildings need to be designed and constructed to withstand the lateral forces and ground shaking caused by seismic activities. Steel H-beams are known for their excellent resistance to bending and torsion, making them ideal for withstanding these forces. Additionally, steel structures offer several advantages in earthquake-prone areas. Steel is flexible, allowing it to absorb and dissipate seismic energy, reducing the impact on the building. Furthermore, steel structures can be designed to have ductile behavior, meaning they can deform under seismic forces without collapsing, providing a higher level of safety. It is important to note that the design and construction of steel structures in earthquake-prone areas must adhere to strict building codes and regulations. These codes specify the required seismic performance levels and design criteria that ensure the safety of the building and its occupants during an earthquake. In conclusion, steel H-beams can be safely and effectively used in earthquake-prone areas when designed and constructed according to the appropriate building codes and regulations. Their strength, flexibility, and ductility make them an excellent choice for structures that need to withstand seismic forces.

- Q: What are the vibration damping properties of steel H-beams?

- Steel H-beams have excellent vibration damping properties due to their high stiffness and mass. The structural design of H-beams allows them to effectively absorb and dissipate vibrations, reducing the potential for resonance and minimizing vibrations transmitted to other components or structures.

- Q: Can steel H-beams be used in data centers and server rooms?

- Yes, steel H-beams can be used in data centers and server rooms. They provide structural support and can help distribute the weight of heavy equipment such as servers and networking devices. Additionally, steel H-beams are fire-resistant, which is crucial in ensuring the safety of the data center and its equipment.

- Q: What is the difference between hot-rolled and cold-formed steel H-beams?

- H-beams made of steel can be produced using two different methods: hot-rolling and cold-forming. These methods result in H-shaped cross-section beams that have distinct characteristics. Hot-rolled steel H-beams are created by heating a large steel billet or ingot to extremely high temperatures and then shaping it through rolling. This process involves intense heat, making the steel more malleable and easier to shape. As a result, the finished product has a rougher surface texture. Hot-rolled H-beams typically have wider flanges and thicker webs compared to cold-formed H-beams. They are commonly used in heavy-duty construction projects that require high strength and load-bearing capacity. On the other hand, cold-formed steel H-beams are manufactured by shaping cold-rolled or galvanized steel coils into the desired H-shaped profile. This process takes place at room temperature, without the use of heat. Cold-formed H-beams have a smoother surface finish and more precise dimensions compared to hot-rolled beams. They also tend to have thinner flanges and webs, making them lighter and more suitable for applications where weight reduction is important. Cold-formed H-beams are commonly used in light to medium-duty construction, such as residential buildings and infrastructure projects. In terms of mechanical properties, hot-rolled H-beams generally have higher yield and tensile strength compared to cold-formed H-beams. This is because the intense heat during the hot-rolling process allows the steel to undergo grain refinement and achieve better mechanical properties. On the other hand, cold-formed H-beams usually have lower strength but higher ductility and toughness. They can deform more before failure, making them more resistant to bending and deformation. In summary, the main differences between hot-rolled and cold-formed steel H-beams lie in the production process, surface finish, dimensions, and mechanical properties. Hot-rolled beams are produced at high temperatures, have a rougher surface, and are used in heavy-duty construction. Cold-formed beams are manufactured at room temperature, have a smoother surface, and are suitable for lighter construction applications.

- Q: Are steel H-beams resistant to earthquakes?

- Due to their strength and structural integrity, steel H-beams are commonly used in construction. They have been proven to be highly resistant to earthquakes. The H-beam's unique shape provides excellent load-bearing capacity and stability, making it a reliable choice for areas prone to earthquakes. One reason why steel H-beams resist earthquakes is their ability to flex without breaking. During an earthquake, the ground shakes and moves in different directions. The flexibility of steel H-beams allows them to absorb and distribute the seismic energy, enabling them to withstand the lateral forces produced by the earthquake. This flexibility prevents the beams from fracturing or collapsing under the intense stress. Furthermore, steel H-beams are renowned for their ductility, meaning they can deform without losing their strength. This quality is particularly important during seismic events. As the ground shakes, the H-beams can flex and bend, absorbing the energy and reducing the impact on the overall structure. This ductility ensures that the beams can withstand the dynamic forces of an earthquake while maintaining their structural integrity. Additionally, steel H-beams possess high tensile strength, allowing them to withstand significant tension. This is crucial during an earthquake when the ground movements can create tension forces within the building. The strong tensile strength of the H-beams enables them to resist these forces and prevent structural failure. In conclusion, steel H-beams are indeed resistant to earthquakes. Their flexibility, ductility, and high tensile strength enable them to withstand the lateral and dynamic forces generated by seismic events. By incorporating steel H-beams into construction designs, engineers can enhance the seismic resistance of buildings and ensure the safety of occupants during earthquakes.

Send your message to us

H-Beam Hot Rolled Steel Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords