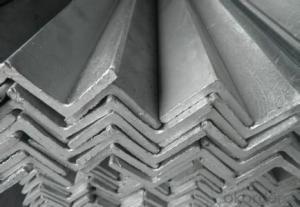

Angle Steel Hot Rolled High Quality ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel Hot Rolled High Quality ASTM A36 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel Angle Steel Hot Rolled High Quality ASTM A36 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1:Would you please tell me the length of angle steel?

A1: 6m and 12m is OK for us.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: How do steel angles contribute to sustainable transportation infrastructure?

- Steel angles contribute to sustainable transportation infrastructure in several ways. Firstly, steel angles are commonly used in the construction of bridges and other transportation structures due to their high strength-to-weight ratio. This enables the creation of lighter, yet durable, structures that require less material and resources for construction. Additionally, steel angles are highly resistant to corrosion, reducing maintenance needs and increasing the lifespan of transportation infrastructure. This longevity reduces the need for frequent repairs or replacements, resulting in lower carbon emissions and reduced waste. Furthermore, steel angles can be easily recycled at the end of their life, promoting a circular economy and reducing the demand for new steel production. Overall, the use of steel angles in transportation infrastructure helps create sustainable and resilient systems that minimize environmental impacts and promote long-term sustainability.

- Q: How do you prevent corrosion between steel angles and other materials?

- To prevent corrosion between steel angles and other materials, there are several effective measures that can be taken: 1. Protective Coatings: Applying a protective coating such as paint, epoxy, or galvanization on the steel angles can create a barrier between the steel and the surrounding materials, preventing direct contact and reducing the risk of corrosion. 2. Insulation: Using insulating materials like rubber or plastic pads or sleeves between the steel angles and other materials can prevent direct contact and minimize the chances of corrosion. 3. Cathodic Protection: By installing sacrificial anodes or using impressed current systems, a cathodic protection mechanism can be established to protect the steel angles. This process involves creating an electrical current that counteracts the corrosion process, keeping the steel angles intact. 4. Regular Maintenance: Regular inspection and maintenance of the steel angles are crucial to identify any signs of corrosion and take appropriate actions promptly. This can include cleaning the surfaces, repairing any damaged coatings, and replacing corroded parts. 5. Proper Drainage: Ensuring proper drainage around the steel angles is essential to prevent moisture accumulation, which can accelerate corrosion. Proper design and installation of drainage systems can prevent water or other corrosive substances from pooling around the steel angles. 6. Avoiding Chemical Exposure: If the steel angles are in an environment where they may come into contact with chemicals or corrosive substances, it is important to choose materials that are resistant to corrosion. This could involve using stainless steel or other corrosion-resistant alloys that can withstand exposure to the specific chemicals present. Overall, implementing a combination of protective coatings, insulation, cathodic protection, regular maintenance, proper drainage, and material selection based on the environment can effectively prevent corrosion between steel angles and other materials, ensuring their longevity and structural integrity.

- Q: Are steel angles fire resistant?

- Steel angles are commonly regarded as fire resistant. This is because steel is a material that does not burn and can withstand high temperatures. Steel angles, which are L-shaped structural components, are widely used in construction and engineering due to their strength and durability. In the event of a fire, steel angles remain structurally intact and do not deform, which is crucial for the safety of a building or structure. However, it is important to consider that the fire resistance of steel angles may be influenced by various factors such as size, thickness, fire protection measures, and the duration and intensity of the fire. To enhance the fire resistance of steel angles and improve overall fire safety, measures like fire-resistant coatings, fire barriers, and fireproofing materials can be employed.

- Q: Can steel angles be used in modular or prefabricated construction?

- Yes, steel angles can be used in modular or prefabricated construction. Steel angles are commonly used as structural components in modular or prefabricated buildings due to their strength, versatility, and ease of installation. They can be easily customized and fabricated to fit specific design requirements, making them suitable for various construction applications in modular or prefabricated projects.

- Q: What are the typical uses for steel angles?

- Various industries and construction projects make extensive use of steel angles. Structural framing is one of the most common applications, where steel angles provide added strength and support to buildings and structures. They play a crucial role in creating bracing, reinforcing, and framing elements like beams, columns, and trusses. Steel angles also find significant use in manufacturing and fabrication. They are employed in the production of machinery, equipment, and vehicles due to their ability to withstand heavy loads without bending or warping. They serve as frames, supports, or brackets for various industrial equipment and machinery. Furthermore, steel angles are widely utilized in furniture manufacturing, particularly in metalwork and carpentry. They function as corner brackets or connectors, offering stability and strength to furniture pieces like tables, chairs, and shelves. Additionally, steel angles are commonly integrated into storage racks and shelving systems to ensure durability and stability when holding heavy loads. In the transportation industry, steel angles are frequently incorporated into the manufacturing of trailers, truck beds, and vehicle frames. Their high strength and resistance to impact and vibrations make them well-suited for these applications, ensuring the longevity and structural integrity of the vehicles. Overall, steel angles have a broad range of uses across various industries and projects. Their versatility, strength, and durability make them a sought-after choice for structural support, manufacturing, furniture construction, and numerous other endeavors that demand robustness and stability.

- Q: How do you connect steel angles to other structural members?

- Steel angles can be connected to other structural members through various methods, such as welding, bolting, or using connector plates.

- Q: Can steel angles be fire-resistant?

- Indeed, steel angles possess fire-resistant qualities. Being a material, steel inherently possesses fire resistance due to its high melting point and low thermal conductivity. When faced with elevated temperatures, steel angles can retain their structural integrity and withstand deformation for a significant duration. Furthermore, fire resistance in steel angles can be augmented through diverse approaches, such as the utilization of fire-resistant coatings or the integration of fire-resistant materials in their design. These measures serve to heighten the fire resistance capacity of steel angles, rendering them appropriate for scenarios where fire protection is imperative, such as the establishment of fire-resistant walls, ceilings, and structural systems in construction projects.

- Q: Can steel angles be used for manufacturing bike racks?

- Yes, steel angles can be used for manufacturing bike racks. Steel angles provide strength and stability required to support the weight of bicycles and withstand outdoor conditions.

- Q: What is the bending capacity of a steel angle?

- The bending capacity of a steel angle refers to its ability to withstand bending or flexing without breaking or deforming excessively. It is a measure of the angle's structural strength and is typically determined by factors such as the dimensions and thickness of the angle, the type of steel used, and any additional reinforcements or supports present. The bending capacity is usually expressed in terms of the maximum amount of load or stress that the angle can endure before it reaches its yield point, which is the point at which it permanently deforms. The bending capacity of a steel angle can vary widely depending on these factors, and it is crucial to consider this capacity when designing and constructing structures that utilize steel angles to ensure their structural integrity and safety.

- Q: Can steel angles be used for platform structures?

- Indeed, platform structures can utilize steel angles. Due to their strength, durability, and versatility, steel angles find frequent application in the construction field. They impart structural support and stability to diverse platform types, such as elevated walkways, mezzanines, catwalks, and scaffolding. With exceptional load-bearing capacity, steel angles endure heavy loads, rendering them apt for platform structures necessitating robustness and stability. Furthermore, the seamless fabrication and assembly of steel angles enable efficient construction and customization of platform structures.

Send your message to us

Angle Steel Hot Rolled High Quality ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords