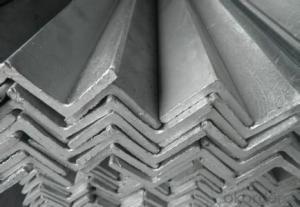

Equal Angle Steel Hot Rolled ASTM A36 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel angles be used for reinforcing steel structures?

- Steel angles are capable of reinforcing steel structures. Their versatility and widespread use in construction projects stem from their strength and durability. Steel angles serve as reinforcements to fortify and provide additional support to steel structures including beams, columns, and trusses. To enhance the overall structural integrity of steel structures, steel angles are often used in conjunction with other reinforcing materials such as steel bars or mesh. The angle shape of steel angles facilitates easy welding or bolting, making them a popular choice for reinforcing steel structures. Moreover, steel angles are available in various sizes and thicknesses, offering flexibility in design and application. All in all, steel angles prove to be an effective and commonly employed option for reinforcing steel structures.

- Q: Are steel angles suitable for supporting rooftop equipment?

- Yes, steel angles are suitable for supporting rooftop equipment. Steel angles offer sturdy support and can withstand the weight and stress of rooftop equipment, making them a reliable choice for this purpose.

- Q: Can steel angles be used in the construction of parking garages?

- Steel angles can indeed be utilized in the construction of parking garages. These angles are frequently employed in construction due to their robustness, durability, and versatility. They have a wide range of structural applications, including the building of parking garages. Steel angles offer support and reinforcement for crucial elements like beams and columns, as well as for framing and bracing. They play a significant role in establishing the framework for parking garage floors and walls, contributing stability and strength to the structure. Moreover, steel angles can be easily fabricated and tailored to meet the precise design and engineering specifications of a parking garage. All in all, steel angles are a favored choice for constructing parking garages because they can endure heavy loads, resist corrosion, and deliver enduring performance.

- Q: Can steel angles be used in telecommunications towers?

- Certainly, telecommunications towers can incorporate steel angles. Due to their robustness, longevity, and cost efficiency, steel angles are frequently employed in the construction of telecommunications towers. They are commonly utilized within the tower's framework to deliver stability and structural reinforcement. The exceptional tensile strength of steel angles enables them to withstand substantial loads, intense winds, and various environmental elements that telecommunication towers may confront. Moreover, the adaptability of steel angles permits customization and seamless installation, rendering them a favored option within the telecommunications sector.

- Q: What are the different manufacturing processes for steel angles?

- Some of the different manufacturing processes for steel angles include hot rolling, cold rolling, and extrusion.

- Q: What is the purpose of using steel angles in construction?

- Steel angles serve various purposes in construction. Their primary function is to offer structural support and stability to different components of a building or structure. Reinforcing corners, edges, and joints, these angles enhance the overall strength and rigidity of the structure. Moreover, steel angles play a crucial role in distributing and transferring loads or forces within the construction. They facilitate the even distribution of weight and stress across various parts of the structure, preventing the formation of weak points. Furthermore, steel angles are highly versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, seamlessly integrating into a wide range of construction projects. Not only that, but steel angles also exhibit remarkable durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With the ability to withstand heavy loads and extreme weather conditions, they provide long-lasting support to the structure. In conclusion, the utilization of steel angles in construction aims to enhance structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: What are the limitations of using steel angles in highly corrosive or chemical environments?

- The limitations of using steel angles in highly corrosive or chemical environments stem from the inherent nature of steel and its vulnerability to corrosion. To begin with, steel angles are primarily composed of carbon steel, which has a tendency to rust when exposed to moisture or chemicals. In environments with high corrosion potential, such as those containing acids, alkalis, or saltwater, the steel angles may corrode at an accelerated rate, which can compromise their structural integrity. Additionally, these steel angles may also experience pitting corrosion in such environments. Pitting corrosion occurs when localized chemical reactions result in the formation of small pits or holes on the steel surface. This phenomenon weakens the angles and diminishes their load-bearing capacity. Another drawback is that steel angles may lack resistance to specific chemicals or substances. Certain chemicals can trigger reactions with the steel, leading to degradation or even catastrophic failure. For example, strong acids or bases can inflict severe damage on the steel angles, potentially resulting in structural collapse. Moreover, steel angles in corrosive environments often require supplementary protective measures like coatings or corrosion inhibitors to enhance their resistance. However, implementing these additional measures can escalate the cost and maintenance demands of the structure. To summarize, while steel angles find widespread use in various applications, their suitability in highly corrosive or chemical environments is limited due to their susceptibility to corrosion and potential chemical reactions. It is crucial to consider alternative materials or employ protective measures to ensure the angles' structural integrity and longevity in such environments.

- Q: Can steel angles be used for fencing and gate construction?

- Indeed, fencing and gate construction can make use of steel angles. The strength and durability of steel angles make them a prevalent choice in construction endeavors. They furnish robust frameworks for fencing and gate structures, delivering support and stability. The process of welding or bolting steel angles together is a simple means of achieving the desired shape and size for fencing and gate construction. Moreover, steel angles possess exceptional resistance to corrosion, rendering them suitable for outdoor applications. In summary, steel angles present themselves as a versatile and dependable option for fencing and gate construction.

- Q: Are steel angles resistant to earthquakes?

- Steel angles can provide some level of resistance to earthquakes. Steel is known for its high strength and ductility, making it a suitable material for seismic-resistant construction. Steel angles, also known as steel L-shaped beams, are often used in structural applications to provide support and reinforcement. During an earthquake, steel angles can help distribute the seismic forces evenly throughout the structure, thereby reducing concentrated stress points. The L-shape design of steel angles enables them to resist bending and twisting forces, which are common during seismic events. Additionally, steel angles can be interconnected and welded together to form a rigid frame system, enhancing their seismic resistance. This system can absorb and dissipate energy from earthquake-induced vibrations, minimizing damage to the structure. However, it is important to note that the overall seismic resistance of a structure depends on various factors, such as the design, construction methods, and adherence to building codes and regulations. Steel angles alone cannot guarantee complete protection against earthquakes, but when properly integrated into a well-designed seismic-resistant system, they can significantly enhance the structure's ability to withstand seismic forces.

- Q: Can steel angles be used in mezzanine flooring systems?

- Indeed, mezzanine flooring systems can incorporate steel angles. In the realm of mezzanine construction, steel angles are frequently employed as structural components due to their remarkable robustness and longevity. Whether utilized as supports, beams, or bracing elements, steel angles offer stability and an impressive load-bearing capacity to mezzanine flooring systems. Moreover, steel angles are adaptable and can be readily tailored and installed to meet precise design specifications. Additionally, they present a cost-effective and dependable solution for generating extra floor area in industrial and commercial edifices.

Send your message to us

Equal Angle Steel Hot Rolled ASTM A36 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords