API Cast Steel Check Valve 80 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

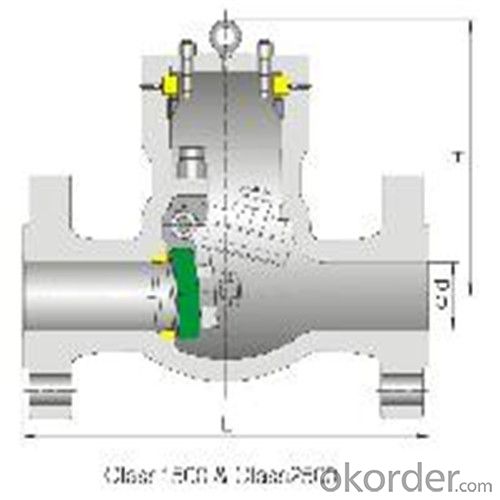

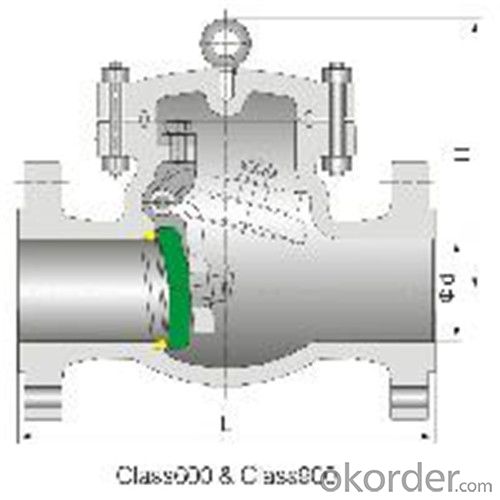

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I just replaced my fill valve and all the other toilet components with a universal korky brand kit about 2 months ago and the fill valve is making a hissing sound once the water fills up in the tank. There are also air bubbles that come from the vents on top of the fill valve. I went to the Korky web site and they say that it is a faulty flapper but i checked to see if there is a leak by dropping one of those testers into the tank and there appears to be no leak. Any suggestions?

- Those valves are notorious for hissing. If it's too loud, turn the service valve down to cut pressure. They are adjustable, so be sure the valve is not filling the tank too close to the overflow. Next time, just use food coloring to test. One or two drops in the tank will do.

- Q: Okay, I got this lawnmower its a craftsman with a briggss and stratton engine, and I use this mower to cut grass in the summer. My question is, I have to get this mower serviced like every 2 weeks. See, the problem is always the valves comes out of adjustment. It only has 2 valves, and a long time ago, I broke one of the studs for the valves. And some guy put another valve on it. Ever since then it hasnt ran good. Iv'e took it many times to get it worked on, and it will run great for about 2 weeks. Then the valves go out it's very hard for it to turn over, and it wont run. Whats the deal here? I hear that you should only have to adjust your valves once a year. What could be wrong?

- haha they have been given me 2 valves briggs and value trans will bypass next shrink your cost now sorry I hate craftsman now they bit me and distinctive others guess ur mower is green with the cup holder,

- Q: I know what a blow off valve is but where does it blow out the air out off does the air blow out threw the exhaust or what?

- Depends on the type of blow off valve. Some vent to atmosphere(just blow it out into open air) others recirculate(blow the air back into the intake farther upstream). Which one it does depends mainly on where the blow off valve is located in the system. If the car has a MAF(mass air flow) sensor and the blow off valve is located after that sensor then it has to be recirculated, because the sensor has already registered that air and if it vents to atmosphere then the engine will run rich because the ECM will be putting too much fuel into the engine.

- Q: Bought a 1986 GMC 350day 1 started up good - idle was rough - idle really too low, when brakes where applied, it would backfire. (day 2) Changed oil which was really dark - oil filter too... ghanged spark plugs and wires. % 10 improvement... Engine lack power and vibrates but no more backfire.day 4 Changed Cap and rotor - % 30 improvement - day 5 Got the manifold gasket replaced. Same condition but silent... day 6 Changed coil in cap ... Changed fuel filter % 60 improvement... The thing ran like new... Full power I started beliving again..Got full oil pressure 300 kpa - no valve noise Ran 30 minutes on highway.... Valves started making noise especially on driver's side... Engine lost lots of power, and vibrates a lot... doesnt heat up to much but oil pressure seems very low. (day 7) Start up the thing, and even when cold and choke on, oil pressure not as good as in the beginning. What went wrong

- I never got to scan any coeds when I worked at AutoZone! There were a few colleges nearby that had plenty of them. Sounds more like you have some carbon built up around your idle air control motor, or the motor may be bad itself. It is located on the side of the throttle body. It is a small passage blocked by a small step motor that pulls away and allows more or less air past the throttle blade, thereby regulating the idle. Throttle position sensor can cause similar problems. Clean the motor and air passage, and test.

- Q: For example, 2 valves from the modular 4.6 is equivalent to 1 valve from the LS1 which is a bigger valve.

- Yes, because the largest 4 valves one can cram in the same cylinder head are smaller BUT provide more area than the largest two valves that would fit in the same head. With valves, the larger the overall area, the better.

- Q: I just dropped my 3rd valve slide from my trumpet on the ground. It fell with the curved end first. I can't see any dents and it doesn't look bent, but I oiled it and everything and it's really hard to move. Could it be bent? How can I fix it?

- Be sure that it is aligned correctly when you place it back in the valve casing. When you are putting it back in, it has to turn until you hear a click, indicating that the valve guide has fallen in the right space. This aligns the valve with all the ports. (The valve guide is a small plastic piece located under the valve spring. This valve guide must snap into a little notch inside the casing. When it does, the valve will be perfectly aligned. You will know when the valve guide is in the right place because you will feel and hear a click and the valve will not rotate any longer.) After thorough cleaning, oiling, and correct valve placement, if you still notice it sticking, take it to a repair shop to have it chemically cleaned. They are typically very good and will ensure your trumpet is in proper playing condition.

- Q: i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- It's hard to say exactly what's wrong without knowing what type of valves you have since different valves have different components. In any case, I'd start by checking that the bleed screw and/or handle (depending on type) and that the flow control screw or handle (again depends on what make/model you have) to make sure they are in good condition and properly set. Be careful when turning these screws or handles don't force them past the normal stopping points. If that all checks out, there may be some dirt or debris stuck in the valve that's not allowing the diaphragm to open all the way.

- Q: I know i have to buy a recirculating valve but should i drop 250 on the perrin or will any brand do? how important is a high quality BOV?

- no importance on brand as long as its a recirculating valve, not a vent to atmosphere.

- Q: I have a question about my car. The mechanic told me that my valve body needed to be rebuilt. However I read that the valve body is a sensor that tells the car when to shift gears. Now my car is a semi automatic so I can shift gears myself! I was wondering if someone could tell me whether it was still necessary to rebuild it if I'm going to be shifting gears myself? I just don't want to mess up the valve body even more and eventually have to get a whole new transmission!

- Its an electrically shifted automatic. The valve body is not a sensor it is the valving system that sends fluid to different parts of the transmission to shift gears. The solenoids on the valve body move the valves dependant on what the computer tells it to do. The paddles or shifter you have do not go to the transmission but to the ECU and the ECU decides what to actually do with the transmission. It does not matter if you shift it or let it do it its self if the transmission is going out it needs work or rebuilt, it WILL fail sooner or later and leave you stranded. So you either need to get it rebuilt or get another transmission. If you drive it until it fail you will need another unit, if you fix it now yours might be able to be saved.

- Q: is there any way to buy refills for empty valve oil bottles, such as holton or al cass

- I wouldn't bother with that. I would go to Woodwind/Brasswind, and get their brand of valve oil. Very economically sound, and a very good product. Why go to all the trouble of getting bulk stuff and trying to put it into those little bottles. Get the company brand stuff. It works wonderfully and is half the price. Sometimes you pay for the names al cass, or holton, when all you are getting is just oil.

Send your message to us

API Cast Steel Check Valve 80 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords