An-Ti Erode PPGI Prepainted Color Coated Steel Sheet Coil Roofing Tile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.An-Ti Erode PPGI/Prepainted Color Coated Steel Sheet/CoilFeatures:

A strong anti-corrosion properties, good corrosion resistance.

The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

A good cold-formed molding processing, users can directly processed into finished products.

Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of An-Ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil

*Used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc,

3.Product Introduction information:

PRODUCT | An-Ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil |

STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

EQUIPMENT | Double coating double baking; three coating three painting |

SUPPLY CAPACITY | 500,000 Tons per Year |

SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

ZINC COATING | 30g/m2-150g/m2 |

PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

COIL ID | 508mm/610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

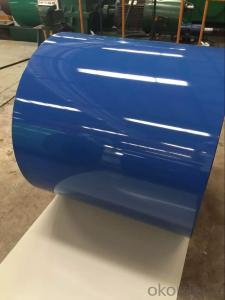

4.An-Ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I just got this aftermarket exhaust on my truck and it's recommended that it be welded, but the metal is aluminized steel. How do I mig weld aluminized steel?

- This Site Might Help You. RE: How to weld aluminized steel? I just got this aftermarket exhaust on my truck and it's recommended that it be welded, but the metal is aluminized steel. How do I mig weld aluminized steel?

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, including roller leveling, stretcher leveling, and temper leveling. In roller leveling, the coil passes through a series of rollers that apply pressure to remove the internal stresses and flatten the material. Stretcher leveling involves stretching the coil beyond its yield point to remove the unevenness and then allowing it to spring back to a flat state. Temper leveling uses heat treatment to relieve the internal stresses and bring the coil to a flat condition. These methods provide different ways to achieve a level and flat surface for steel coils.

- Q: Hi,Well, I live near almost across the street from a forest, and my neighborhood is full of raccoons!!! Recently, I just purchased a bunny and have kept it at my cousin's house for the time being. He has a steel cage, and is about 6 months old. I am considering bringing him home and leaving him in the back yard with his steel cage. I am just afraid that raccoons can bite through the steel and get to him. So the question is... Is is possible for raccoons to bite through steel? Btw,Please don't answer hate comments about me being a bad rabbit owner. I simply want to know if raccoons can bite through steel. If it doesn't work out, the rabbit will stay at my cousins house until further notice. But please, I did not waste 5 points for unneeded answers. Thanksss!

- Well the raccoons can't bite through steel unless it is very thin steel, like aluminum foil thickness. But they have long arms and can reach into the cage so that would be my worry. They are also very clever so I don't know if it is safe for the bunny. That would depend upon the size of the cage and how hungry the raccoons are. The raccoons might be tempted to try to steal the bunny's food so that is a concern. Check with a pet shop owner or forester or someone like that who has knowledge about raccoons in the area.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry can vary depending on the specific requirements and applications. However, there are some common dimensions that are widely used. The most common coil width ranges from 600mm to 2000mm, although it can be as narrow as 100mm or as wide as 2500mm in certain cases. The coil thickness typically ranges from 0.5mm to 6mm, but it can go up to 25mm for specialized applications. The inner diameter of the coil, known as the core diameter, is usually between 508mm and 610mm. The weight of steel coils can vary significantly depending on the width, thickness, and length of the coil. However, a standard steel coil can weigh anywhere from 3 to 20 tons. It is important to note that these dimensions are not fixed and can be customized based on the specific storage system requirements and the industry in which they are used.

- Q: How do steel coils compare to aluminum coils?

- Steel coils and aluminum coils possess distinct characteristics that render them suitable for varying purposes. Firstly, steel coils are renowned for their robustness and durability. They can endure high temperatures and exhibit greater resistance to damage in comparison to aluminum coils. Consequently, steel coils are an ideal choice for heavy-duty industrial applications necessitating sturdy materials, such as construction, automotive manufacturing, and the oil and gas industries. Additionally, steel coils boast heightened corrosion resistance, enabling their usage in outdoor environments characterized by harsh conditions. On the contrary, aluminum coils are lighter in weight and possess a higher strength-to-weight ratio than steel coils. This renders them exceptionally well-suited for industries wherein weight serves as a critical factor, such as aerospace and transportation. Furthermore, the malleability of aluminum coils facilitates easier shaping and forming, thereby proving advantageous in industries like packaging and consumer electronics. Moreover, aluminum coils exhibit superior thermal conductivity when compared to steel coils, rendering them more efficient in heat transfer applications. This particular attribute proves beneficial in industries such as HVAC (heating, ventilation, and air conditioning) and refrigeration, where the achievement of efficient heat exchange is of utmost importance. Concerning cost, steel coils generally prove more affordable due to the lower cost of raw materials. However, aluminum coils can yield long-term cost savings as they require less maintenance and possess a longer lifespan owing to their resistance to corrosion. In conclusion, the selection between steel coils and aluminum coils hinges on the specific requirements of the application at hand. Steel coils are favored for their strength, durability, and corrosion resistance, while aluminum coils excel in lightweight applications, heat transfer, and malleability.

- Q: What are the common coil lengths available for steel coils?

- The steel coil lengths offered in the industry and specific requirements are subject to variation. Nonetheless, several standard coil lengths are extensively employed in different applications. These encompass coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths find extensive use in construction, manufacturing, and automotive sectors, where steel coils serve diverse purposes. It is worth mentioning that coil lengths can also be tailored to meet specific project requirements or customer preferences.

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- Easy. okorder /

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- Steel is better. Acrylic is porous so isn't as suitable for piercing jewellery as steel. Steel can also slide through easier for some people, acrylic isn't quite as smooth. For tapers it doesn't make a huge deal of difference as they're only passing through your ear briefly, not being worn as jewellery, but if they're close in cost anyway then go for the steel. And the plugs you insert after putting the taper through should always be steel, titanium or glass until your stretch has healed.

- Q: What are the different steel coil packaging methods?

- There are several different steel coil packaging methods, including using steel strapping, wrapping with plastic or stretch film, placing the coils in wooden crates, or using steel coil sleeves or eye-to-sky packaging.

- Q: I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- I'm looking too and certainly the designer trend is to buy stainless steel. They look classy, shiny and bring a darker wood kitchen more life. However, there are companies that have put out fingerprint/smudge free stainless models. I have found their surfaces don't retain fingerprints - do test them in the store.If you have small children, stainless isn't the best choice. I love the look and practicality of the French Door fridges - great for smaller spaces. I was all set to buy an LG fridge and now I'm hearing that they're going on fire? Be sure to check Consumer Reports before you buy. Many of the cheaper models are now made in Mexico. I do notice the quality difference when I'm opening and closing fridge doors in the showrooms.

Send your message to us

An-Ti Erode PPGI Prepainted Color Coated Steel Sheet Coil Roofing Tile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords