An-ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil/PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

An-ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil

1. Detailed Specifications:

| Product | An-ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

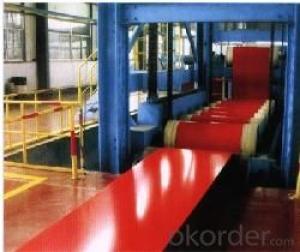

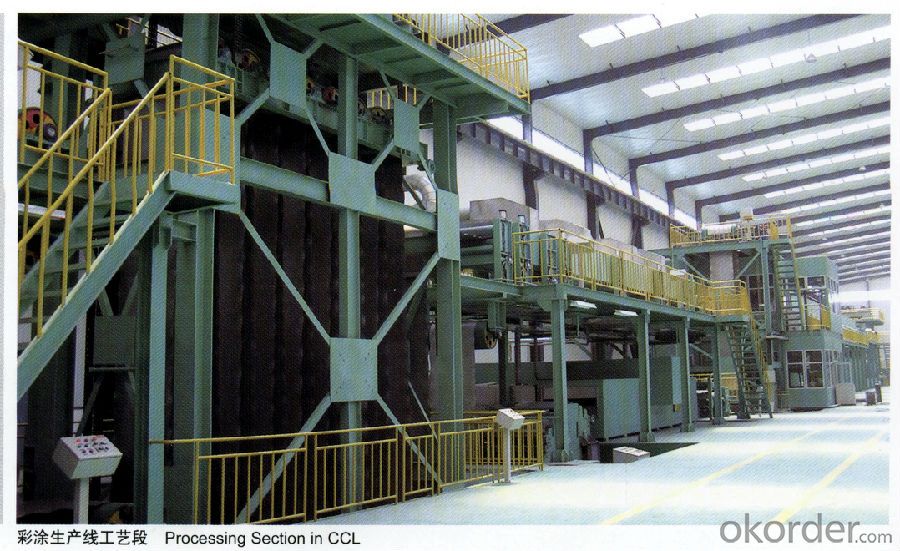

3. Image:

production Line:

production show:

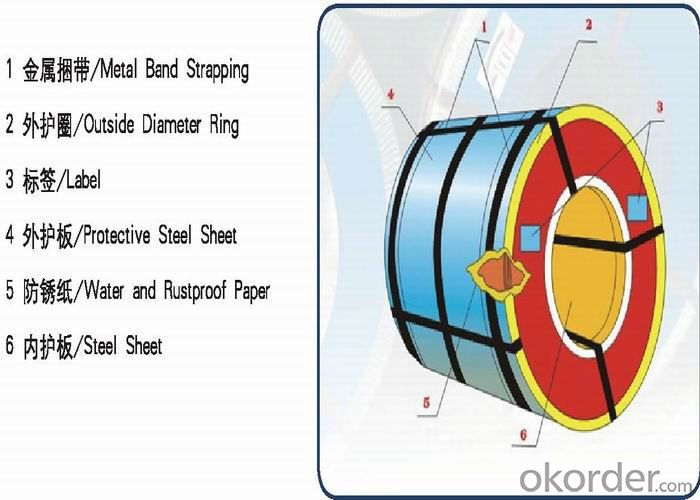

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q: What is the minimum thickness of a steel coil?

- The specific grade and type of steel being used, along with the manufacturing process, can cause the minimum thickness of a steel coil to vary. Generally, a steel coil is typically about 0.001 inches (0.0254 millimeters) thick. It is worth mentioning that this value is a general rule and may change depending on the industry's or application's specific requirements and standards.

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel Rod Tompkins Steel Blaze Tompkins Steel Adam Tompkins

- Q: I know of the cheaper steel shot for waterfoul hunting, but there is more expensive shot available. Is it worth the money, how much more distance are we talking, and what do you like the best?(brand name)

- In my experience with steel shot, I found that the higher quality stuff usually just patterns more consistently. Although I prefer Federal, any of the other major manufactuers are also great.

- Q: Can steel coils be coated with zinc?

- Yes, steel coils can be coated with zinc through a process called galvanizing. This coating provides protection against corrosion and increases the durability and longevity of the steel coils.

- Q: How are steel coils used in the manufacturing of food packaging?

- Steel coils are commonly used in the manufacturing of food packaging as they provide strength and durability to the packaging materials. These coils are typically shaped into cans, containers, or lids, ensuring the preservation and protection of food products during storage and transportation. Steel coils help maintain the integrity of the packaging, preventing breakage or damage that could compromise the safety and quality of the food.

- Q: How are steel coils processed for further use?

- Steel coils are processed for further use through a series of steps that include uncoiling, leveling, cutting, and sometimes additional treatments such as galvanizing or painting. These processes ensure that the steel coils are prepared and ready to be used in various industries such as automotive, construction, or manufacturing.

- Q: What are the different types of steel coil finishing tools?

- In the metalworking industry, various tools are utilized to finish steel coils, resulting in enhanced appearance and functionality. Common examples of these tools include: 1. Slitting Machines: These machines effectively cut large steel coils into narrower strips by utilizing sharp circular blades. The outcome is multiple smaller coils with desired widths. 2. Levellers: Used to flatten and straighten steel coils, levellers apply pressure to ensure a perfectly flat and even coil. They are particularly beneficial when coils have undergone deformation during the manufacturing process. 3. Recoilers: After slitting or levelling, recoilers rewind steel coils into a tighter and more compact shape. This process is carried out to create coils of specific diameters or sizes. 4. Edge Trimmers: To eliminate excess or uneven edges from steel coils, edge trimmers are utilized. They efficiently remove burrs, rough edges, and any other imperfections, resulting in a clean and smooth finish. 5. Inspection Machines: These machines are employed to examine the quality of steel coils. They detect defects such as surface imperfections, scratches, or dents, ensuring that only high-quality coils are delivered to customers. 6. Coating Machines: To provide protective coatings to steel coils, coating machines are utilized. These coatings, such as paint, zinc, or other materials, prevent corrosion and enhance coil durability. 7. Packaging Machines: Packaging machines securely wrap steel coils, protecting them during transportation and storage. These machines employ plastic or metal straps, shrink wrap, or other packaging materials to ensure the coils remain intact and undamaged. Overall, these diverse steel coil finishing tools are essential in the metalworking industry, enabling manufacturers to produce high-quality and visually appealing steel coils that meet specific customer requirements.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is also a coil, usually a narrow strip, also known as a steel strip. The volume is relatively wide. In addition, flat steel is usually hot-rolled out of long strip steel, fixed length 5 and 5.5,6 meters range, steel coil is Kaiping Chang 12501500, length 2.5 meters, 4 meters, 6 meters, ranging from steel plate

- Q: steel welding with ms steel iron

- Welding austenitic stainless steels to carbon and low alloy steels are established methods in the process and construction industries. Dissimilar metal welds involving stainless steels can be done using most full fusion weld methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Weld procedures using filler (consumable) enable better control of joint corrosion resistance and mechanical properties. In selecting the weld filler, the joint is considered as being stainless, rather than the carbon steel. Over-alloyed fillers are used to avoid dilution of the alloying elements in the fusion zone of the parent stainless steel.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils vary widely depending on the specific type and purpose of the coil. Generally, steel coils can range anywhere from a few hundred pounds to several tons in weight.

Send your message to us

An-ti Erode PPGI/Prepainted Color Coated Steel Sheet/Coil/PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords