Aluzinc Galvanized Steel Coils (for Ventilated Duct)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluzinc Galvanized Steel Coils (for Ventilated Duct)

Description of Aluzinc Galvanized Steel Coils (for Ventilated Duct)

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Aluzinc Galvanized Steel Coils (for Ventilated Duct)

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

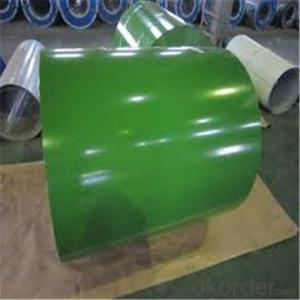

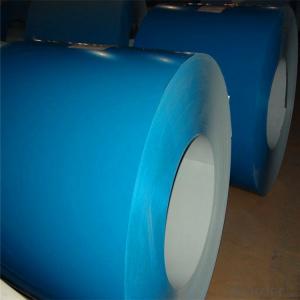

Products Show of Aluzinc Galvanized Steel Coils (for Ventilated Duct)

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the specific requirements for special steel used in the mining industry?

- To ensure the durability, strength, and resistance to harsh conditions of special steel used in the mining industry, certain requirements must be met. Key requirements for this type of steel include: 1. High tensile strength is necessary to withstand heavy loads and resist deformation under extreme conditions. This enables the steel to endure the pressure, impact, and stress encountered during mining operations. 2. Excellent wear resistance is essential to prevent premature failure and increase the lifespan of mining equipment in abrasive environments. Rocks and ores can cause significant wear on the equipment. 3. High corrosion resistance is crucial in highly corrosive mining environments, such as underground mines or areas near water bodies. The steel should be able to withstand exposure to chemicals, moisture, and other corrosive agents to prevent rusting, pitting, and other forms of corrosion that weaken the steel. 4. Excellent toughness is required to withstand heavy impacts and vibrations that mining equipment is subjected to. If the steel is not tough enough, fractures can occur. The steel must be able to absorb energy from impacts and vibrations without fracturing, ensuring the safety and reliability of the equipment. 5. Good heat resistance is necessary to withstand high-temperature mining operations, such as smelting and refining processes. The steel should not lose its strength or undergo deformation under elevated temperatures. 6. Good machinability is important to allow for easy formation of complex shapes or structures. This facilitates the manufacturing process of mining equipment and components. Overall, meeting these requirements is crucial for ensuring the reliability, durability, and safety of mining equipment in demanding mining environments.

- Q: How does special steel perform in abrasive environments?

- Special steel performs exceptionally well in abrasive environments due to its high hardness, superior resistance to wear and tear, and excellent corrosion resistance. It is specifically designed to withstand the harsh conditions of abrasive environments, such as those with sand, gravel, or other abrasive particles. The unique composition and properties of special steel enable it to maintain its integrity and durability even when exposed to extreme abrasion, making it an ideal choice for applications in industries like mining, construction, and manufacturing.

- Q: What are the challenges in casting special steel?

- One of the challenges in casting special steel is the high melting point of the material. Special steels often have a higher carbon content or alloying elements, which increases their melting point. This requires the use of specialized furnaces and techniques to reach and maintain the necessary temperature for casting. Additionally, special steels can be prone to defects such as porosity, inclusions, and segregation during the casting process. These defects can negatively impact the mechanical properties and overall quality of the steel, making it difficult to achieve the desired specifications. Therefore, strict control over the casting conditions, including temperature, mold design, and pouring techniques, is crucial to overcome these challenges and produce high-quality special steel castings.

- Q: What are the different methods of surface anodizing for special steel?

- There are several methods of surface anodizing for special steel, each with its own advantages and applications. Here are some of the different methods: 1. Chromic Acid Anodizing: This method involves immersing the steel in a solution of chromic acid. It forms a thin, hard, and corrosion-resistant oxide layer on the surface of the steel. Chromic acid anodizing provides excellent adhesion for paint and other coatings, making it suitable for applications requiring enhanced durability and aesthetic appeal. 2. Sulfuric Acid Anodizing: Sulfuric acid anodizing is one of the most widely used methods. It involves immersing the steel in a sulfuric acid bath and applying a direct current to create an oxide layer on the surface. This method offers excellent corrosion resistance, increased hardness, and improved wear resistance. It also provides a good base for applying dyes or sealing to achieve various colors and finishes. 3. Phosphoric Acid Anodizing: Phosphoric acid anodizing is commonly used for stainless steel. It involves immersing the steel in a solution of phosphoric acid and applying a direct current. This process creates a protective oxide layer that improves corrosion resistance and provides a uniform matte finish. Phosphoric acid anodizing is often used for applications where a decorative appearance is not required. 4. Titanium Anodizing: This method involves anodizing steel with titanium electrodes. It creates a thick oxide layer on the surface, resulting in improved corrosion resistance, increased hardness, and enhanced wear resistance. Titanium anodizing is commonly used in industries such as aerospace, where strong and durable surface properties are essential. 5. Hard Anodizing: Hard anodizing is a specialized process that produces a thick and highly durable oxide layer on the steel surface. It involves using a higher voltage and lower temperature in the anodizing process, resulting in improved hardness, wear resistance, and electrical insulation properties. Hard anodizing is often used in applications requiring superior abrasion resistance, such as parts subjected to heavy wear or friction. These are just a few of the different methods of surface anodizing for special steel. The selection of the most suitable method depends on the specific requirements of the application, desired properties, and the type of steel being treated. It is important to consult with experts in the field to determine the optimal anodizing method for a particular steel application.

- Q: What are the different tooling grades of special steel?

- Special steel is a category of steel that has been designed and manufactured to possess specific characteristics or properties, making it well-suited for various industrial applications. Within special steel, there are different tooling grades available, each with its own unique composition and properties. These grades are specifically engineered to meet the demands of different tooling applications, ensuring optimal performance and durability. Some common tooling grades of special steel include: 1. High-Speed Steel (HSS): HSS is a type of tool steel that exhibits excellent hardness, wear resistance, and heat resistance, making it ideal for high-speed cutting tools such as drills, milling cutters, and taps. It retains its hardness even at elevated temperatures, enabling it to maintain cutting performance without losing its edge. 2. Hot Work Tool Steel: Hot work tool steel is designed to withstand high temperatures and thermal cycling encountered in applications such as hot forging, die casting, and extrusion. It possesses good toughness, high heat resistance, and excellent wear resistance, allowing it to retain its strength and shape even under extreme thermal conditions. 3. Cold Work Tool Steel: Cold work tool steel is primarily used for cutting and forming applications at lower temperatures. It exhibits a high level of hardness, toughness, and wear resistance, making it suitable for applications such as blanking, shearing, and cold forming. Cold work tool steel maintains its hardness even under compressive forces, ensuring long-lasting performance. 4. Plastic Mold Steel: Plastic mold steel is specifically designed for the production of plastic injection molds and related tooling. It possesses excellent machinability, high polishability, and good wear resistance, allowing it to withstand the demanding conditions encountered during plastic molding processes. Plastic mold steel ensures precise and high-quality molding performance. 5. Powder Metallurgy (PM) Steel: PM steel is a tooling grade that is manufactured using a powder metallurgy process. This method allows for the production of complex shapes, uniform microstructure, and improved properties. PM steels are commonly used in high-performance cutting tools, wear-resistant parts, and high-strength applications. These are just a few examples of the different tooling grades available in special steel. Each grade is carefully engineered to meet the specific requirements of various tooling applications, ensuring optimal performance, durability, and efficiency in different industrial sectors.

- Q: What are the different food processing grades of special steel?

- In the food industry, there are numerous special steel grades used for food processing. These grades are tailor-made to meet the stringent requirements of food processing, guaranteeing product safety and quality. One widely employed grade of special steel for food processing is AISI 304 stainless steel. This grade is renowned for its exceptional resistance to corrosion, making it suitable for environments where food is processed. Additionally, it exhibits high resistance to chemicals and acids, enhancing its suitability for food processing applications. Another frequently utilized grade in the food industry is AISI 316 stainless steel. This grade offers superior corrosion resistance compared to AISI 304 and is commonly employed in applications involving direct contact between equipment and food or food-related substances. Furthermore, AISI 316 stainless steel withstands high temperatures, making it suitable for use in food processing operations that involve intense heat. Moreover, specific food processing grades of special steel have been developed for environments with stringent hygiene requirements. These grades, such as AISI 316L and 1.4404, possess a smoother surface finish, preventing bacterial buildup and facilitating easier cleaning. Overall, the various grades of special steel used in food processing offer different levels of resistance to corrosion, temperature, and hygiene. These characteristics ensure that the steel utilized in food processing equipment is durable, safe, and compliant with industry standards.

- Q: What are the cost considerations when using special steel?

- When using special steel, there are several cost considerations that need to be taken into account. Firstly, the cost of the raw materials used to produce special steel can be significantly higher compared to regular steel. Special steel is often made from alloying elements such as chromium, nickel, or molybdenum, which can be more expensive than the iron and carbon used in regular steel production. These alloying elements improve the properties of the steel, making it stronger, more corrosion-resistant, or better suited for specific applications. Additionally, the production process for special steel may involve additional steps or specialized equipment, leading to increased manufacturing costs. This can include steps such as vacuum degassing, controlled cooling, or precision forging, all of which contribute to the quality and performance of the final product but can also add to the overall cost. Furthermore, because special steel is often tailored to meet specific requirements or industry standards, there may be additional testing and certification costs involved. These can include non-destructive testing, material analysis, or third-party inspections to ensure that the steel meets the required specifications. These additional quality control measures can add to the overall cost of using special steel. Finally, the demand and availability of special steel can also impact its cost. If the demand for certain types of special steel is high or the supply is limited, prices may be driven up. This can be particularly relevant for industries that require specialized steel grades, such as aerospace, automotive, or oil and gas. In summary, the cost considerations when using special steel include the higher cost of raw materials, the additional manufacturing steps, the testing and certification requirements, and the overall supply and demand dynamics of the market. However, it is important to note that the benefits and advantages of using special steel, such as improved performance, durability, or specific properties, can often outweigh the higher costs, making it a worthwhile investment for many industries.

- Q: Can special steel be used for making chemical processing equipment?

- Yes, special steel can be used for making chemical processing equipment. Special steel, such as stainless steel or corrosion-resistant alloys, are commonly used in the construction of chemical processing equipment due to their excellent resistance to corrosion, high temperature and pressure, and ability to withstand harsh chemical environments.

- Q: How does special steel contribute to the defense sector?

- The defense sector relies heavily on special steel, which offers numerous benefits and applications that bolster national security. First and foremost, special steel is renowned for its exceptional strength, durability, and resistance to wear and corrosion. These attributes make it an ideal material for manufacturing military equipment and weapons. Tanks, armored vehicles, naval ships, and aircraft carriers all benefit from the structural integrity and protection against enemy attacks provided by special steel. Furthermore, the use of special steel in ballistic armor and bulletproof vests enhances the safety of soldiers on the battlefield. Additionally, special steel alloys possess remarkable thermal resistance and high-temperature capabilities, making them suitable for producing jet engines, turbines, and rocket components. These materials can withstand extreme conditions, enabling faster and more efficient military aircraft, missiles, and vehicles used in space exploration. Moreover, special steel's electromagnetic properties make it invaluable in the defense sector. It is employed in developing radar systems, communication devices, and electronic warfare equipment. Special steel alloys effectively shield against electromagnetic interference, ensuring secure and reliable communication during critical defense operations. Furthermore, special steel plays a vital role in the production of precision tools and machinery used in the defense sector. With its high machinability, special steel enables the fabrication of complex components with tight tolerances. Military-grade cutting tools, drills, and machine parts are manufactured using special steel, thereby enhancing the efficiency and effectiveness of military operations. In conclusion, special steel significantly contributes to the defense sector by providing crucial properties such as strength, durability, resistance, and more. Its applications in military equipment, weaponry, armored vehicles, aircraft, and electronic systems not only enhance national security but also protect soldiers and enable advanced defense capabilities.

- Q: How are copper alloys used in electrical applications?

- Copper alloys are extensively used in electrical applications due to their excellent electrical conductivity and thermal properties. They are used in the production of electrical wires, connectors, and busbars, ensuring efficient transmission of electricity. Copper alloys also offer good corrosion resistance, making them suitable for outdoor and marine electrical systems. Additionally, their high strength and ductility allow for easy fabrication and installation in various electrical components.

Send your message to us

Aluzinc Galvanized Steel Coils (for Ventilated Duct)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords