Aluzinc Curragated Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

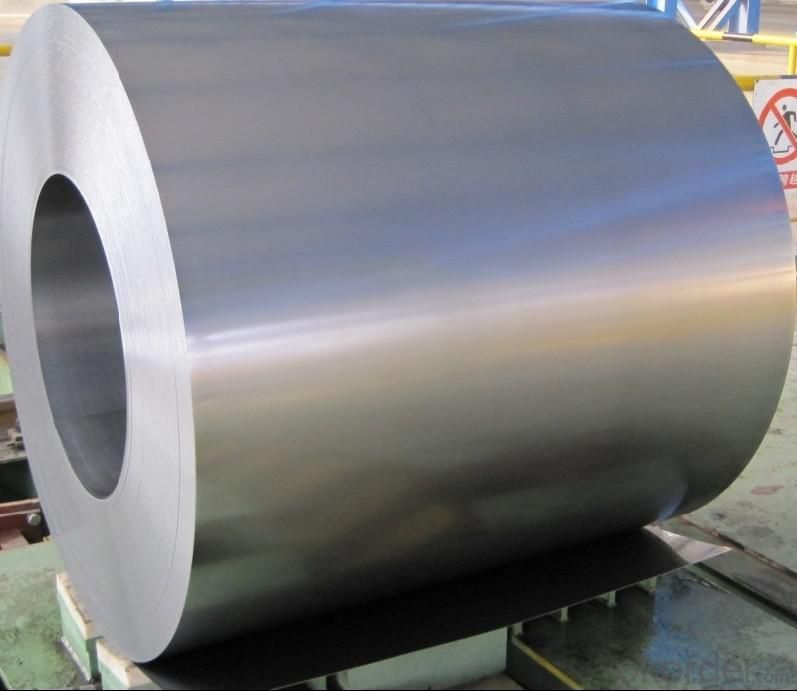

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the different joining methods for steel sheets?

- There exist several methods for joining steel sheets, each with its own benefits and applications. 1. Welding, a widely used method, involves melting and fusing the sheet edges together with heat. Various welding techniques, such as arc, MIG, TIG, and spot welding, are available. Welding ensures robust and durable joints but demands skilled operators and can be time-consuming. 2. Bolting, another method, employs bolts or screws to connect steel sheets. This method is commonly preferred when disassembly or maintenance is necessary. Bolting guarantees strong and reliable joints, and it is relatively simple and quick. However, it may involve drilling holes and result in a less visually appealing appearance compared to welding. 3. Riveting, a method utilizing metal pins or rivets, effectively joins steel sheets. Rivets are inserted through pre-drilled holes and then deformed or expanded to secure them in place. Riveting ensures strong and secure joints, commonly used in applications requiring high shear strength. Nevertheless, it can be time-consuming and necessitates specialized tools and skills. 4. Adhesive bonding involves using specialized adhesives or bonding agents to join steel sheets. The adhesive is applied between the sheets and forms a strong bond as it cures. Adhesive bonding provides excellent aesthetics, leaving no visible joints, and evenly distributes stress across the joint. It finds common use in industries where welding or other methods are unsuitable, such as automotive and aerospace sectors. 5. Clinching utilizes mechanical force to join steel sheets. It entails deforming the sheet edges to interlock them and create a strong joint. Clinching is cost-effective as it does not require additional materials like fasteners or adhesives. However, it may not be suitable for applications requiring high load-bearing capacity. Ultimately, the choice of joining method for steel sheets depends on factors such as the application, desired strength, aesthetics, time constraints, and cost considerations. Each method possesses its own advantages and limitations, necessitating the selection of the most appropriate method for the specific project requirements.

- Q: Can the steel sheets be used as a magnetic surface?

- Indeed, the use of steel sheets as a magnetic surface is possible. Steel, being a ferromagnetic material, possesses the ability to be magnetized and maintain its magnetism even when the magnet is no longer present. This characteristic enables steel sheets to attract and secure magnetic items. In numerous scenarios, steel sheets are widely employed as magnetic surfaces, including magnetic boards, magnetic whiteboards, and magnetic organizers. By employing magnets, it becomes effortless to affix notes, documents, and additional magnetic objects onto steel sheets, rendering them a practical and adaptable means of organization and exhibition.

- Q: What material is steel plate against drilling?

- All high nickel, high tungsten, or both titanium (tungsten carbide and titanium carbide), cobalt, molybdenum, niobium and other elements of the steel can be drilled.

- Q: Can steel sheets be used for noise reduction purposes?

- Yes, steel sheets can be used for noise reduction purposes. Steel is a dense and rigid material that has good sound insulation properties. When properly installed as barriers or enclosures, steel sheets can effectively block and absorb sound waves, reducing noise levels in various applications including buildings, machinery, and vehicles.

- Q: Can steel sheets be used for construction equipment?

- Construction equipment can indeed utilize steel sheets. Steel, a versatile and long-lasting material, finds widespread use in the construction industry for a range of purposes, including equipment fabrication. Steel sheets can be manipulated, joined, and shaped into various components and structures required for construction equipment like bulldozers, cranes, excavators, and dump trucks. The remarkable strength-to-weight ratio of steel renders it suitable for heavy-duty equipment, providing the necessary robustness and steadiness while managing weight effectively. Furthermore, steel boasts corrosion resistance, a crucial quality for construction equipment that confronts harsh environmental conditions. In summary, owing to their strength, durability, and versatility, steel sheets enjoy considerable popularity as a preferred option for construction equipment.

- Q: What are the dimensions of steel sheets?

- The dimensions of steel sheets can vary depending on the specific requirements and applications. However, commonly available steel sheets come in standard sizes such as 4 feet by 8 feet or 5 feet by 10 feet. Additionally, steel sheets can be found in various thicknesses ranging from thin gauges (e.g., 28 gauge) to thicker options (e.g., 16 gauge).

- Q: Can steel sheets be used for outdoor sculptures or artwork?

- Yes, steel sheets can be used for outdoor sculptures or artwork. Steel is a durable material that can withstand outdoor conditions and can be shaped and welded into various artistic forms. Its strength and resistance to corrosion make it suitable for outdoor installations, allowing for the creation of long-lasting and visually appealing sculptures and artwork.

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets can vary compared to fiberglass sheets depending on a variety of factors. In general, fiberglass sheets tend to be less expensive than steel sheets. This is primarily because the raw materials used in steel sheet production are more costly, and the manufacturing process is more complex. Furthermore, steel sheets are renowned for their durability and strength, making them a popular choice for applications that require resilience and resistance to harsh weather conditions or impact. Conversely, fiberglass sheets are typically cheaper due to the lower cost of raw materials and the simpler manufacturing process involved. They are commonly employed in applications where weight and corrosion resistance are crucial factors, such as the construction of boats or aircraft. Nevertheless, it is important to acknowledge that market fluctuations, availability, and specific project requirements can also influence the cost comparison between steel and fiberglass sheets. Hence, it is advisable to obtain quotes from suppliers and compare prices to accurately determine the average cost within a given context.

- Q: Can steel sheets be heat treated for increased hardness?

- Yes, steel sheets can be heat treated to increase their hardness.

- Q: Are the steel sheets resistant to vibration or shock?

- Yes, steel sheets are generally resistant to vibration and shock. Steel is known for its high strength and durability, making it capable of withstanding external forces such as vibrations and shocks. The rigid nature of steel allows it to absorb and distribute the energy caused by vibrations or shocks, preventing any significant damage or deformation. Additionally, steel sheets are often used in applications where resistance to vibrations and shocks is crucial, such as in construction, automotive, and aerospace industries. However, it is important to note that the exact resistance of steel sheets to vibration or shock will depend on factors such as the thickness and quality of the steel used, as well as the specific magnitude and frequency of the vibrations or shocks.

Send your message to us

Aluzinc Curragated Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords