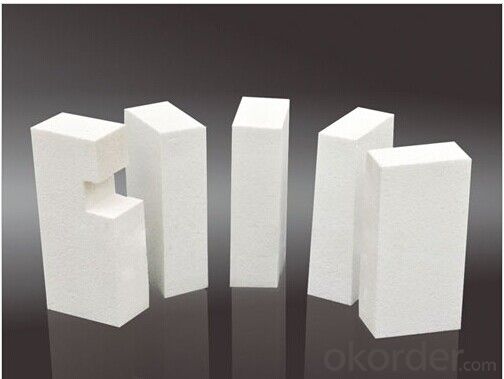

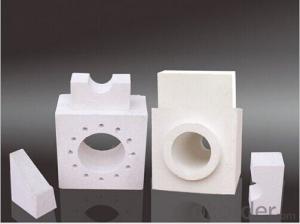

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. High temperature resistance.

2. Good thermal insulation.

3. Professional manufacturer.

Alumina hollow ball brick, Alumina bubble brick , Alumina hollow sphere brick , Hollow alumina sphere bricks

Alumina hollow ball brick used the alumina hollow ball,corundum powder,and calcined powders mixed at definite proportion as raw material. After mixing, drying, forming, firing at high temperature shuttle kiln made.

Physical and chemical index:

Item | ZYL-84 | ZYL-90 | ZYA-1.2 | ZYA-1.5 | ZYA-1.7 |

Al2O3 % ≥ | 84 | 90 | 98.5 | 98.5 | 98.5 |

Fe2O3 % ≤ | 0.8 | 0.5 | 0.3 | 0.3 | 0.3 |

SiO2 % ≤ | 15 | 9 | 1.0 | 1.0 | 1.0 |

Bulk density, g/m3,≤ | 1.5 | 1.5 | 1.2 | 1.5 | 1.7 |

Porosity,%, ≥ | 58 | 60 | 62 | 60 | 58 |

CCS,Mpa, ≥ | 16 | 15 | 3 | 12 | 15 |

Thermal conductivity, 1000°C,( W/m.k )≤ | 1.2 | 1.15 | 0.95 | 1.05 | 1.15 |

0.1Mpa RUL,°C ≥ | 1650 | 1700 | 1700 | 1700 | 1700 |

Refractoriness,°C ≥ | 1800 | 1800 | 1800 | 1800 | 1800 |

Characteristic:

1. High temperature resistance.

2. Low thermal conductivity.

3. Good thermal insulation.

4. High strength.

5. Can direct contact with flame.

6. Good chemical stability (acid-base erosion resistance ).

7. Low bulk density (lighter than the same kind of material ,thin kiln wall, low cost ) .

- Q: Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks require minimal maintenance. They are designed to withstand high temperatures and are resistant to cracking or crumbling. However, regular cleaning to remove any debris or buildup is recommended to maintain their insulating properties and extend their lifespan.

- Q: Are insulating fire bricks resistant to erosion?

- Yes, insulating fire bricks are generally resistant to erosion. Insulating fire bricks are made of lightweight materials such as alumina, silica, or a combination of both. These materials have excellent resistance to erosion caused by high temperatures, chemical reactions, and physical wear. They are designed to withstand extreme heat and harsh conditions, making them highly durable against erosion. Additionally, insulating fire bricks have low thermal conductivity, which means that they do not absorb or transfer heat easily, further protecting them from erosion. However, it is important to note that the resistance to erosion may vary depending on the specific composition and quality of the insulating fire bricks.

- Q: Can insulating fire bricks be used in refractory coatings?

- Yes, insulating fire bricks can be used in refractory coatings. They provide excellent thermal insulation properties and can help in maintaining high temperatures while minimizing heat loss.

- Q: Can insulating fire bricks be used in the construction of heat shields?

- Certainly, heat shields can indeed be constructed using insulating fire bricks. These bricks are specifically designed to withstand elevated temperatures and possess exceptional thermal insulation properties. Their ability to effectively absorb and distribute heat makes them an ideal choice for the creation of heat shields, which serve to safeguard against excessive heat and mitigate thermal damage. In industries that involve high temperatures, such as steel, glass, and ceramics, insulating fire bricks are frequently employed. Moreover, their lightweight nature and ease of handling make them a practical option for constructing portable or easily installable heat shields. In summary, insulating fire bricks are a reliable and appropriate material for constructing heat shields in a diverse range of applications.

- Q: Can insulating fire bricks be used in chimneys and fireplaces?

- Chimneys and fireplaces can indeed utilize insulating fire bricks. These bricks are specifically crafted to endure high temperatures and offer exceptional insulation. They are constructed from lightweight materials like ceramic fibers or refractory materials, which aid in minimizing heat transfer. Thus, they are an optimal choice for lining chimneys and fireplaces since they retain heat within the firebox and prevent its escape through the chimney. Moreover, insulating fire bricks enhance the heating system's efficiency by reducing heat loss and elevating the overall heat output. However, it is crucial to emphasize that insulating fire bricks should only be employed in appropriate sections of the chimney or fireplace, such as the firebox. Conversely, the smoke chamber or flue necessitate different types of bricks capable of withstanding the corrosive effects of flue gases.

- Q: Can insulating fire bricks be used in the construction of steam generators?

- Indeed, the utilization of insulating fire bricks is possible in the construction of steam generators. Specifically engineered to possess superior thermal insulation properties, these bricks are well-suited for applications necessitating elevated temperatures and thermal stability. Given that steam generators function at high temperatures and necessitate efficient heat transfer, insulation becomes indispensable for preventing heat dissipation and enhancing energy efficiency. By enduring extreme temperatures and offering effective insulation, insulating fire bricks diminish heat losses and enhance the overall effectiveness of steam generators. Furthermore, their lightweight composition facilitates easy handling and installation during the construction process. Therefore, insulating fire bricks represent a fitting choice for the construction of steam generators.

- Q: Can insulating fire bricks be used for flooring insulation?

- No, insulating fire bricks are not suitable for flooring insulation as they are primarily designed for use in high-temperature applications like fireplaces, furnaces, and kilns. Flooring insulation requires materials that can withstand foot traffic, moisture, and other stresses that insulating fire bricks may not be able to handle effectively.

- Q: Do insulating fire bricks have a high fire resistance rating?

- Yes, insulating fire bricks have a high fire resistance rating. These bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them ideal for applications where fire resistance is crucial. They can withstand temperatures as high as 3000°F (1650°C), making them highly reliable in various industrial and residential settings that require protection against extreme heat.

- Q: Can insulating fire bricks be used as insulation for pizza ovens?

- Yes, insulating fire bricks can be used as insulation for pizza ovens. Their high heat resistance and ability to retain heat make them an ideal choice for insulating the oven and maintaining the desired temperature for baking pizzas.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Insulating fire bricks exhibit exceptional resistance to weathering and aging. These bricks are specifically engineered to endure extreme temperatures and harsh environmental conditions. They are composed of top-notch refractory materials, including alumina, silica, and other additives, which confer exceptional thermal insulation properties and strong resistance to corrosion and erosion. The manufacturing process of insulating fire bricks entails meticulous selection of raw materials and precise control of firing temperatures, resulting in a dense and homogeneous structure. This structure effectively prevents moisture and other weathering agents from infiltrating, thus ensuring extended durability and resistance to aging. Moreover, insulating fire bricks are also highly resistant to thermal shock, enabling them to withstand rapid temperature fluctuations without fracturing or disintegrating. This characteristic bolsters their ability to withstand adverse weather conditions. All in all, insulating fire bricks have demonstrated remarkable dependability in diverse applications that involve exposure to weathering elements. They find widespread usage in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

Send your message to us

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords