Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

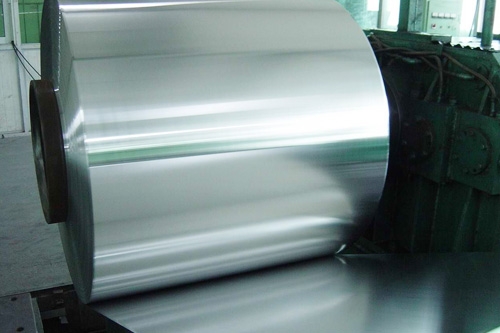

Cold rolled aluminum sheet ,The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.we have a good reputationin the field of aluminium material, besides, we are one global 500 enterprise, so you can really feel free for our production quality, if you are interested in any of our products, feel free to show us your detailed inquiries later, we give you best price, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

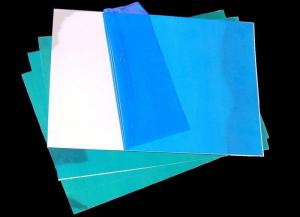

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1100mm*2200mm,1200mm*2400mm,1220mm*2440mm,1500mm*6000mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the width range?

---It is from 1000mm to 2500mm, etc.

where is your client from?

----normally they are from UAE, ARAB, SINGAPORE, INDONESIA, ETC.

How many tons did they order in one year?

---normally it is around 9000 tons totally.

what is your MOQ now?

---normally it is around 5 tons/eah size.

how often did client place one order yet?

---it is around 1 month, etc.

what is your mainly products?

---Normally they are aluminum sheet, aluminum coil, chekcered sheet, mirror finish sheet, etc.

On the material terms: the cost price of aluminum is five times more than the cost price of iron, it is to count the cost of recycling, a price of aluminum is a hair, a tin price is 2 points, chose the high cost of embossing aluminum evaporator because the aluminum evaporative cooling effect is best, ordinary refrigerator uses wire tube evaporator in order to save costs, cut corners!

Embossed aluminum embossed aluminum plate and can be referred to as: aluminum plate on the basis of belonging through the rolling process in a variety of patterns formed on the surface of aluminum products, is widely used, and mainly used in packaging, construction, walls, and so on.

Aluminum refers to aluminum or aluminum alloy material processed into (cut or sawn) obtained by pressure rectangular cross section, material thickness uniform rectangular international customary to more than 0.2mm thickness, 500mm or less, 200mm width above, aluminum length 16m or less called aluminum sheet aluminum sheet, 0.2mm or less as aluminum foil, a width of less than 200mm row material or strip (of course with the progress of large equipment, the widest 600mm can be achieved exclusive material will be more).

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Aluminum wiring contracts and expands more than copper wiring of similar size. This means that it has a tendancy to loosen the screws on the outlets over time. As the screws loosen, the resistance in the circuit goes up - this resistance manifests itself as heat. If it gets too hot, it can start fires. My parents owned a house with aluminum wiring, that they sold to me. In the 35 years total we've owned it, I think we've tightened the screws on the outlets three times total. Only once in all that time have we had a wall get hot. The most recent tightening was during a major repainting where we actually replaced the outlets and switches with decorator ones as we painted each room.

- Q: This question asks for the cost of an aluminum sheet.

- <p>The cost of aluminum sheets can vary significantly based on factors such as thickness, grade, surface finish, and market conditions. As of my last update, the price range for aluminum sheets could be anywhere from $0.50 to $5 per pound, but this is subject to change. For the most accurate and current pricing, it's best to check with suppliers or on metal exchange platforms, as prices can fluctuate daily. Always consider the specific requirements of your project to determine the exact type and grade of aluminum needed, which will also affect the cost.</p>

- Q: Can the aluminum sheets be used for heat dissipation purposes?

- Yes, aluminum sheets can be used effectively for heat dissipation purposes due to their excellent thermal conductivity.

- Q: Are 101 aluminum sheets magnetic?

- No, 101 aluminum sheets are not magnetic. Aluminum is a non-magnetic metal, which means it does not attract or hold a magnetic charge.

- Q: What are the effects of utilizing aluminum sheets on the environment?

- <p>The environmental impact of using aluminum sheets includes both positive and negative aspects. On the positive side, aluminum is recyclable, and its use in construction and manufacturing can reduce the need for more energy-intensive materials like steel. However, the production process of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Despite these concerns, aluminum's lightweight nature can reduce energy consumption in transportation, and its durability can extend the lifespan of products, reducing waste. Overall, the environmental impact depends on the balance between these factors and the specific context of use.</p>

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The surface treatment of aluminum sheet can greatly affect its appearance. Different treatments such as anodizing, coating, or polishing can alter the texture, color, and shine of the aluminum surface. Anodizing can create a protective oxide layer while also providing a range of colors. Coatings can add a layer of paint or protective film, giving the aluminum a smooth or textured finish and providing various color options. Polishing can enhance the reflectivity of the aluminum, giving it a shiny and mirror-like appearance. Overall, the surface treatment plays a crucial role in determining the final look and visual appeal of the aluminum sheet.

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can be used for aircraft skin panels. In fact, aluminum is the most commonly used material for aircraft skin panels due to its favorable properties. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal choice for constructing aircraft. Additionally, aluminum is easily formable, allowing it to be shaped into the desired contours and curves required for aircraft design. It also has good heat conductivity, which helps to dissipate heat generated during flight. Overall, aluminum sheet is a reliable and efficient material for aircraft skin panels.

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve various colors and finishes. The process typically involves pre-treating the surface, applying a primer, and then applying the desired paint or coating. This allows for customization and aesthetic enhancement of aluminum sheets in numerous applications.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords