All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum sheets affected by exposure to corrosive chemicals and harsh industrial environments?

Aluminum sheets are generally resistant to corrosion, especially when compared to other metals. However, when exposed to corrosive chemicals and harsh industrial environments, they can still be affected to some extent. The severity of the impact will depend on the specific chemicals involved and the duration of exposure. Aluminum may undergo pitting corrosion, where localized damage in the form of small holes or pits can occur on the surface. Additionally, certain chemicals can cause aluminum to experience general corrosion, resulting in a gradual degradation of the metal. To mitigate these effects, protective coatings or treatments can be applied to aluminum sheets to enhance their resistance to corrosion in such environments.

What is the thermal expansion coefficient of different aluminum sheet alloys and its implications for various applications?

The thermal expansion coefficient of different aluminum sheet alloys varies, but generally ranges between 22 and 24 x 10^-6 per °C. This coefficient measures how much the material expands or contracts when subjected to temperature changes. High thermal expansion coefficients can lead to dimensional changes in aluminum sheets, making them more susceptible to warping, buckling, or cracking. Therefore, for applications where dimensional stability is crucial, such as in architectural or aerospace industries, aluminum alloys with lower thermal expansion coefficients are preferred. However, in applications where thermal conductivity or heat dissipation is important, alloys with higher thermal expansion coefficients can be advantageous. Overall, understanding the thermal expansion characteristics of aluminum sheet alloys is essential for selecting the most suitable material for specific applications.

How do you remove dents and imperfections from aluminum sheets?

To remove dents and imperfections from aluminum sheets, you can try various methods. One common technique is using a heat gun or hairdryer to warm up the dented area. This helps to make the aluminum more flexible, allowing you to gently push the dent out from the backside using a soft mallet or rubber hammer. Another approach is using a suction cup or vacuum dent puller to pull the dent outwards. You can also try using dry ice, applying it to the dent and then quickly heating the area with a hairdryer, causing the metal to contract and pop the dent out. In case of deeper dents or scratches, sanding the area with progressively finer sandpaper followed by polishing can help achieve a smoother finish.

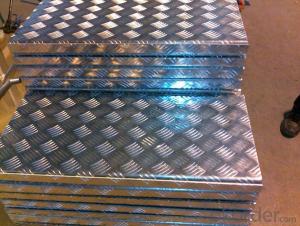

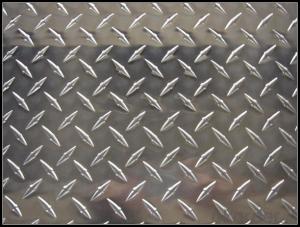

Wholesale Aluminum Sheets from supplier in Uzbekistan

Whether you are in need of Aluminum Sheets for construction, manufacturing, or any other application, we have the right solution for you. Our Aluminum Sheets are made from high-quality materials and are available in various sizes, thicknesses, and finishes to meet your specific requirements.

When you choose to partner with us, you can expect excellent customer service from our dedicated team. We understand the importance of timely delivery and strive to ensure that your orders are processed and shipped promptly. Our knowledgeable sales team is always available to assist you with any inquiries or technical support you may need.

At CNBM, we are committed to providing our customers with the best value for their money. We offer competitive pricing on all our Aluminum Sheets, without compromising on quality. Our strong relationship with suppliers allows us to negotiate favorable terms, which we pass on to our customers.

In addition to supplying Aluminum Sheets, we also offer comprehensive after-sales services. If you encounter any issues or have any questions regarding our products, we are here to assist you. Our technical support team is well-versed in the properties and applications of Aluminum Sheets and can provide you with expert advice.

Partner with us for all your Aluminum Sheet needs in Uzbekistan and experience the convenience and efficiency of working with a trusted and reliable supplier. Contact us today for sales, quotations, or any other inquiries. We look forward to serving you and contributing to the success of your projects.

When you choose to partner with us, you can expect excellent customer service from our dedicated team. We understand the importance of timely delivery and strive to ensure that your orders are processed and shipped promptly. Our knowledgeable sales team is always available to assist you with any inquiries or technical support you may need.

At CNBM, we are committed to providing our customers with the best value for their money. We offer competitive pricing on all our Aluminum Sheets, without compromising on quality. Our strong relationship with suppliers allows us to negotiate favorable terms, which we pass on to our customers.

In addition to supplying Aluminum Sheets, we also offer comprehensive after-sales services. If you encounter any issues or have any questions regarding our products, we are here to assist you. Our technical support team is well-versed in the properties and applications of Aluminum Sheets and can provide you with expert advice.

Partner with us for all your Aluminum Sheet needs in Uzbekistan and experience the convenience and efficiency of working with a trusted and reliable supplier. Contact us today for sales, quotations, or any other inquiries. We look forward to serving you and contributing to the success of your projects.