Copper Aluminum Coils Lennox Aluminum Sheet for Roofing and Cladding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The Specification of Coated Aluminium Sheel:

Commodity | 1050 Aluminum Sheet / Plate |

Material | 1050,1060,1100,2A16(LY16),2A06(LY6),3003,3004,5052,5005,5083, 6061,7075,8011 |

Finish (Surface) | Hairline Finish,Mirror Finish,Oxidation Finish,PS Finish,Embossed Finish |

Thickness | 0.15mm~200mm |

Width | 10mm~2500mm |

Length | 2000mm~2500mm |

Aluminum Sheet can apply to Lighting,solar reflective film,building

appearance,interior decorating:Ceilings,walls, furniture,cabinets,elevators, signs,

nameplates,bags,automotive interior and exterior decoration Upholstery:Photo

Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc.

aerospace and military aspects, such as China's large aircraft manufacturing,the

Shenzhou spacecraft series,satellite.the mechanical parts processing,mold

making,chemical/thermal insulation pipes coated.

The Main Features of Aluminium Coated Sheet:

1.High temperature resistant

2.Weathering resistance

3.Scrubbing resistant

4.Sound insulation

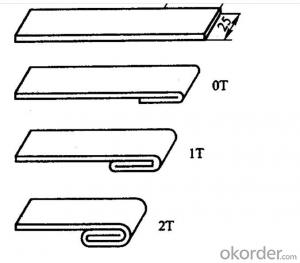

The Images of Aluminium Coated Coil:

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q: How long do aluminum coils typically last?

- The typical lifespan of aluminum coils is approximately 15 to 20 years, but their longevity is heavily influenced by various factors including the quality of the aluminum, the installation process, and the maintenance and care given to them. The lifespan of the coils can be significantly prolonged by regularly maintaining them, such as by cleaning the coils and ensuring adequate airflow. Moreover, their durability can also be affected by environmental factors like exposure to severe weather conditions and corrosive substances. Hence, ensuring proper care and maintenance is crucial to guarantee the extended lifespan of aluminum coils.

- Q: How are aluminum coils processed for specific mechanical properties?

- Aluminum coils are processed for specific mechanical properties through various methods such as heat treatment, cold working, and alloying. Heat treatment involves heating the coils to specific temperatures and then cooling them rapidly or slowly to enhance their strength, hardness, or ductility. Cold working, which includes processes like rolling or drawing, applies pressure to the coils to increase their strength and improve their mechanical properties. Alloying the aluminum coils with other elements can also modify their mechanical properties by enhancing their strength, corrosion resistance, or other desired characteristics. Overall, a combination of these processes is employed to achieve the desired mechanical properties in aluminum coils.

- Q: What are the different grades of aluminum used in coil production?

- Coil production utilizes various grades of aluminum, each possessing its own unique properties and characteristics suitable for specific purposes. Some commonly employed grades include: 1. Commercially pure aluminum, known as 1100 Aluminum, excels in corrosion resistance and boasts high thermal conductivity. It finds applications in heat exchangers, fin stock, and evaporator coils. 2. 3003 Aluminum, alloyed with manganese, offers increased strength and durability compared to 1100 aluminum. Its formability and weldability properties make it suitable for a wide range of coil production applications, such as roofing, gutters, and general sheet metal work. 3. Magnesium alloyed 5052 Aluminum exhibits exceptional corrosion resistance and high strength. It is frequently utilized in marine applications like boat hulls and components, as well as architectural and automotive applications. 4. Renowned for its high strength and excellent machinability, 6061 Aluminum is considered one of the most versatile aluminum alloys. It commonly finds use in structural applications like aircraft parts, truck frames, and industrial equipment. 5. The aerospace and defense industries commonly rely on 7075 Aluminum, which offers one of the highest strength aluminum alloys. It demonstrates excellent fatigue resistance and is often employed in the production of aircraft wing spars, fuselage frames, and missile components. These examples highlight the diverse grades of aluminum employed in coil production. The selection of a specific grade depends on the desired properties and requirements of the intended application.

- Q: How to identify the quality of color coated aluminum coil and sheet?

- Color coated aluminum coil is a kind of aluminum coil. As for qualified color coated aluminum coil, the surface has no impression, holiday and damage through the coating, and also no ripple, scratch and swell. All these are easy to see. However, the most important is the color difference of the color coated aluminum coil which is not obvious but will influence the decoration effect. Now the surface of curtain wall aluminum sheet will also be treated with electrostatic spraying. The power coating materials can have dozens of colors and realize good decorative effect, with polyurethane, polyethylene expansion resin and epoxy resin as raw materials, high color retention pigment as auxiliaries.

- Q: What industries commonly use aluminum coils?

- Aluminum coils are commonly used in a variety of industries including automotive, aerospace, construction, HVAC (heating, ventilation, and air conditioning), electrical, packaging, and transportation.

- Q: How are aluminum coils used in the production of musical instruments?

- Aluminum coils are commonly used in the production of musical instruments, particularly in wind instruments like saxophones and trumpets. These coils are shaped into a specific design and attached to the instrument to create the desired sound. The aluminum material allows for a lightweight and durable construction, enhancing the instrument's playability and resonance.

- Q: Is it possible to utilize aluminum coils in the manufacturing process of solar panels?

- <p>Yes, aluminum coils can be used in the production of solar panels. Aluminum is a common material used in solar panel frames due to its lightweight, high strength, and excellent heat dissipation properties. It also offers good resistance to corrosion, which is crucial for outdoor applications. Aluminum coils are often chosen for their ease of manufacturing and cost-effectiveness, making them a suitable choice for constructing the frame or support structure of solar panels.</p>

- Q: who discovered aluminum and in what year did they discover it?

- discovered by Sir Humphrey Davy in 1808 Sir Humphrey Davy was from Britain he also named it Aluminum as its name xD

- Q: How do aluminum coils compare to other metal coils like steel or copper?

- Aluminum coils offer several advantages and disadvantages when compared to other metal coils like steel or copper. In terms of weight, aluminum coils are significantly lighter than steel coils. This makes them easier to handle and transport, which can reduce costs in the manufacturing and construction industries. On the other hand, steel coils are much stronger and more durable than aluminum, making them more suitable for heavy-duty applications where strength is crucial. In terms of corrosion resistance, aluminum coils have a natural oxide layer that protects them from rust and corrosion. This makes them an excellent choice for outdoor applications or environments with high humidity. Copper coils also have excellent corrosion resistance, but steel coils are more prone to rust and require additional protective coatings. Thermal conductivity is another factor to consider. Copper is known for its exceptional thermal conductivity, making it highly efficient for applications that require heat transfer, such as HVAC systems. Aluminum coils have lower thermal conductivity than copper, but they are still widely used in various heat transfer applications due to their lightweight and cost-effectiveness. Cost is a significant consideration when comparing different metal coils. Aluminum coils are generally more affordable than copper and steel coils, which makes them a popular choice for many industries. However, steel coils are often the most cost-effective option for heavy-duty applications due to their strength and durability. Overall, the choice between aluminum, steel, or copper coils depends on the specific requirements of the application. Each metal has its own unique properties and advantages, and selecting the right material involves considering factors such as weight, strength, corrosion resistance, thermal conductivity, and cost.

- Q: need to know the procedure for removal of aluminum windows with brick trim

- 1st off let`s determine what kind of windows you have. Examine the inside of the jambs. Are there any screws going through the jamb into the rough opening? If so you have a masonary style window. Chances are they can be removed relatively easily. Most the time removal of fastners,scoring of drywall and caulk and they practically fall out (sometimes). You may find removal of the sash and remaining glass, then collasping the frame will work best. This technique is a must if you have the other breed of window, the flanged. You can ID this window by measuring the inside and out . If they`re the same, it`s flanged. I`ve found 99 time out of 100 these windows can be collasped. Once again remove sash and all glass. Here`s where the sawsall comes in. Remove the center bar. Drive a flat bar under the sill from the exterior. Pry it up as high as you can. Cut the sill. Now drive the flat bar between the side jambs and the brick and start prying. Most of the time these windows are only nailed on the corners, sometimes the fin will rip from the jamb. But in the end the removal will be accomplished. If you find you need to pry from the interior, don`t pry against drywall. Put a piece of wood under your bar to protect the drywall. NEVER! pry on tile or marble. I`ve removed literally thousands of these little buggers. Can`t only remember maybe a handful of times I had to cut a flange. GOOD LUCK!!!!!

Send your message to us

Copper Aluminum Coils Lennox Aluminum Sheet for Roofing and Cladding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords