Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

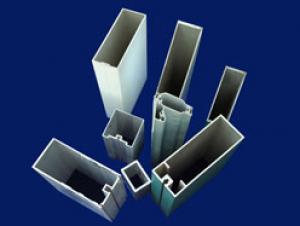

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

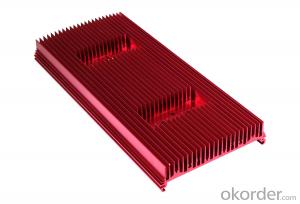

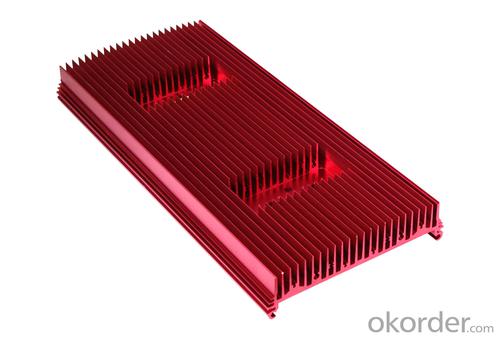

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks if aluminum profiles can be used in outdoor settings and seeks an explanation for their suitability.

- <p>Yes, aluminum profiles can be used for outdoor applications. They are suitable for outdoor use due to their high resistance to corrosion, which is a result of the natural oxide layer that forms on aluminum when exposed to air. This layer protects the aluminum from further oxidation and damage. Additionally, aluminum profiles are lightweight, strong, and can withstand various weather conditions, making them ideal for applications such as outdoor furniture, construction, and signage. Their durability and low maintenance requirements also contribute to their popularity in outdoor settings.</p>

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: Do aluminum profiles require regular maintenance?

- Maintenance is necessary for aluminum profiles. However, the frequency and extent of maintenance depends on how they are used and the environment they are in. Although aluminum profiles are known for being durable and resistant to corrosion, they can still become dirty, grimy, and oxidized over time. To keep them clean and looking good, it is recommended to regularly clean them with mild soap or detergent and water. It is also a good idea to lubricate any moving parts, like hinges or sliding mechanisms, to ensure they operate smoothly. Additionally, it is important to inspect the profiles for any signs of damage, such as cracks or loose connections, so that any issues can be addressed before they get worse. By doing regular maintenance, the lifespan of aluminum profiles can be extended and their performance can be optimized.

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: Can aluminum profiles be utilized in creating distinctive architectural designs and styles?

- <p>Yes, aluminum profiles can be used to create unique architectural designs and styles. They are favored for their strength, durability, and versatility. Architects can manipulate aluminum to achieve a wide range of shapes and structures, from sleek modern designs to traditional styles with a contemporary twist. Aluminum's lightweight nature and resistance to corrosion make it an ideal material for both interior and exterior applications, allowing for creative freedom in architectural expression.</p>

- Q: Can aluminum profiles be used in the production of agricultural machinery?

- Yes, aluminum profiles can be used in the production of agricultural machinery. Aluminum is a lightweight and durable material that can withstand harsh environmental conditions, making it suitable for various components and structures in agricultural machinery. Additionally, aluminum profiles offer flexibility in design and can be easily customized to meet specific requirements, enhancing the efficiency and performance of agricultural equipment.

- Q: This question asks about the various types of aluminum profiles that are utilized for the purpose of exterior wall cladding.

- <p>Aluminum profiles for exterior wall cladding come in various types, each serving specific design and structural needs. Common types include: 1. Flat Profiles, which are simple and versatile for basic cladding. 2. Box Profiles, offering a sleek, modern look and are often used for commercial buildings. 3. L-Profiles, used for corner sections and providing structural support. 4. U-Channels, which are used for concealing fasteners and creating a clean appearance. 5. Angle Profiles, used for creating corners and edges. 6. Special Profiles, designed for specific architectural features. Each type is chosen based on the aesthetic, structural integrity, and weather resistance required for the project.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the field of commercial construction.

- <p>Commonly used aluminum profiles in commercial construction include: 1. Extruded aluminum profiles, which are versatile and can be customized for various applications. 2. Structural aluminum framing, used for building structures and curtain walls. 3. Aluminum window and door frames, known for their durability and energy efficiency. 4. Aluminum handrails and railings, important for safety in commercial buildings. 5. Aluminum trusses, used for roof structures and large spans. 6. Aluminum angles and channels, used for support and framing. 7. Aluminum tubes, used in various structural and decorative applications. These profiles are chosen for their strength, lightweight, corrosion resistance, and ease of maintenance.</p>

- Q: Are aluminum profiles suitable for modular office systems?

- Yes, aluminum profiles are suitable for modular office systems. Aluminum is a lightweight and versatile material that offers various advantages for modular office systems. Firstly, aluminum profiles are highly durable and have excellent strength-to-weight ratio, making them suitable for supporting various structures and office components. They can withstand heavy loads and provide stability to the modular system. Secondly, aluminum profiles are corrosion-resistant, which is crucial for office environments that may have moisture or humidity. This ensures that the modular office system will maintain its integrity and appearance over time. Additionally, aluminum profiles offer design flexibility, allowing for customization and adaptation to different office layouts and requirements. They can be easily modified, cut, and assembled to create a modular system that meets specific needs. This flexibility also allows for future expansion or reconfiguration of the office space. Furthermore, aluminum profiles are environmentally friendly, as they are recyclable and have a low carbon footprint compared to other materials. This aligns with the growing trend of sustainable and eco-friendly office design. In conclusion, aluminum profiles are highly suitable for modular office systems due to their durability, corrosion resistance, design flexibility, and environmental benefits.

- Q: What materials are used for aluminum profile packing?

- Aluminum packaging standard is generally pearl cotton and kraft paper packaging, but depends on the degree of product requirements,

Send your message to us

Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords