Aluminum Extrusion Profiles New York - Aluminum Sections 002

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

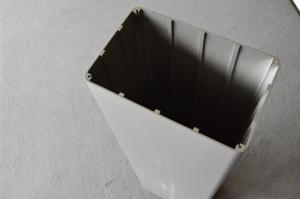

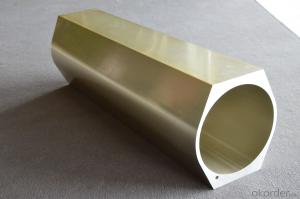

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

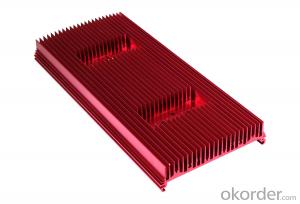

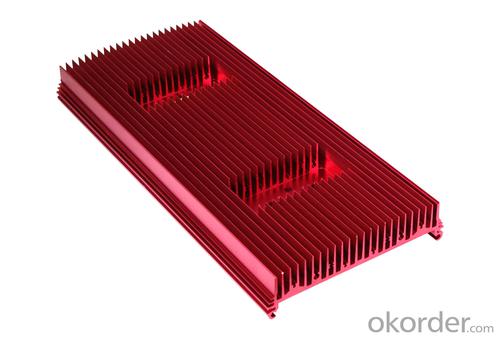

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: How much is the 5000 ton aluminum profile extrusion machine? What section can I have?

- It's more expensive than I thought. Thank you!Chasing the answerCheap, some people have to do, but large extruder manufacturers less, less than 3000 tons better.

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Tensile properties, hardness, coating thickness

- Q: This question asks for methods to prevent aluminum profiles from rusting during the storage and transportation phases.

- <p>To prevent rusting of aluminum profiles during storage and transportation, follow these steps: 1. Keep the profiles dry and clean, avoiding contact with moisture and corrosive substances. 2. Store them in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging, such as plastic wrapping or anti-corrosion paper, to shield the profiles from moisture and contaminants. 4. Ensure proper ventilation in storage areas to prevent condensation. 5. Avoid stacking profiles directly on the ground; use pallets or racks to elevate them and allow air circulation. 6. Regularly inspect the profiles for signs of corrosion and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rusting during storage and transportation.</p>

- Q: What are the safety regulations concerning the use of aluminum profiles in construction?

- <p>Yes, there are safety regulations related to the use of aluminum profiles in construction. These regulations vary by country and region but generally include requirements for material strength, durability, and resistance to environmental factors. Standards such as ASTM B221 for aluminum and aluminum alloy extruded bars, rods, and profiles, and ISO 6361 for aluminum and aluminum alloy extruded profiles, provide guidelines on dimensions, tolerances, and mechanical properties. Compliance with local building codes and regulations is crucial, which may include fire resistance, load-bearing capacity, and corrosion resistance. Additionally, proper installation practices and adherence to manufacturer's specifications are essential to ensure safety and structural integrity.</p>

- Q: This question asks for methods to guarantee the reliability of aluminum profiles used in a construction project.

- <p>To ensure the quality of aluminum profiles in your building project, first, source from reputable suppliers with a proven track record. Request for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and straightness. Check for surface defects like scratches or dents. Ensure the profiles meet the required strength and durability standards by requesting test reports or conducting your own tests. Verify the alloy composition to ensure it's suitable for your project's environmental conditions. Lastly, consider the manufacturer's warranty and after-sales service as an indicator of their confidence in product quality.</p>

- Q: What does aluminum 6063 T5 mean?

- 6063 is the material composition, and T5 is the material heat treatment state

- Q: Are aluminum profiles suitable for outdoor use and can they withstand weathering?

- <p>Yes, aluminum profiles can be used for outdoor applications. They are resistant to corrosion and weathering due to their inherent properties and can be anodized or powder coated for additional protection against the elements. This makes them suitable for a variety of outdoor uses such as construction, furniture, and signage. However, it's important to ensure that the profiles are properly finished and maintained to prolong their lifespan and performance outdoors.</p>

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the construction of commercial buildings.

- <p>Commonly used aluminum profiles in commercial buildings include: 1. Extruded aluminum profiles, which are versatile and used for window frames, door frames, and curtain walls. 2. Structural aluminum profiles, used for load-bearing structures and support systems. 3. Architectural aluminum profiles, designed for aesthetic and functional purposes like facades and decorative elements. 4. Industrial aluminum profiles, used in manufacturing and assembly lines. 5. Thermal break aluminum profiles, which reduce heat transfer and are used in energy-efficient buildings. 6. Anodized aluminum profiles, offering enhanced durability and corrosion resistance. These profiles are chosen based on specific project requirements, such as structural needs, design aesthetics, and environmental considerations.</p>

Send your message to us

Aluminum Extrusion Profiles New York - Aluminum Sections 002

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords