Royal Brown Aluminum Coil - Aluminum Mill Finished Coils 8xxx for Constructions

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 100000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Mill Finished Coils 8XXX Used in Constructions Description

Aluminum Mill Finished Coils 8XXX Used in Constructions has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Mill Finished Coils 8XXX Used in Constructions is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Mill Finished Coils 8XXX Used in Constructions

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

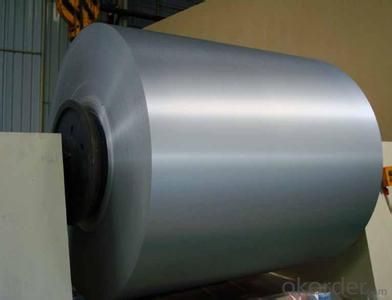

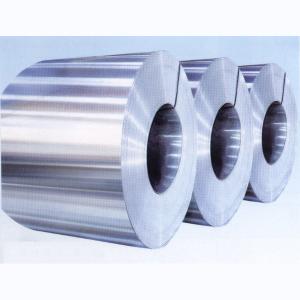

3.Aluminum Mill Finished Coils 8XXX Used in Constructions Images

4.Aluminum Mill Finished Coils 8XXX Used in Constructions Specification

Alloy | AA8xxx (AA8011 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Mill Finished Coils 8XXX Used in Constructions

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Mill Finished Coils 8XXX Used in Constructions.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum is a lightweight and corrosion-resistant material that has excellent thermal conductivity. These properties make it suitable for various applications where low-friction is desired. In industries such as automotive, aerospace, and HVAC systems, aluminum coils are often used in heat exchangers, evaporators, condensers, and cooling coils. These coils are designed to efficiently transfer heat, while minimizing friction and energy loss. Additionally, aluminum coils can be used in electrical motors, generators, and transformers, where low friction is essential for smooth operation and reduced energy consumption. The lightweight nature of aluminum also helps to reduce the overall weight of the system, leading to improved efficiency. Furthermore, aluminum coils can be utilized in various types of machinery and equipment that require low friction, such as conveyor systems, sliding mechanisms, and bearings. Aluminum's low coefficient of friction allows for smooth and efficient movement, minimizing wear and tear on the components. Overall, aluminum coils are a versatile solution for low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Their use can lead to improved energy efficiency, reduced maintenance costs, and enhanced performance in a wide range of industries.

- Q: Can aluminum coils be fabricated or formed into different shapes?

- Aluminum coils possess the capability to be transformed into diverse forms through fabrication or shaping. Thanks to its malleability, aluminum can be effortlessly manipulated and molded without any fear of cracking or rupturing. Various techniques including bending, rolling, and stamping can be employed to alter the shape and design of the coils. Consequently, these coils can be subsequently processed or joined together to manufacture products with distinct geometries, such as automotive parts, kitchenware, electrical elements, or even architectural edifices. The pliability of aluminum as a material opens up a broad spectrum of possibilities in terms of configuring and giving it different structures.

- Q: What are the safety considerations when handling aluminum coils?

- When handling aluminum coils, there are several safety considerations that need to be taken into account. Firstly, it is important to understand that aluminum coils can be quite heavy, especially when dealing with larger sizes. Therefore, proper lifting techniques should be used to avoid strain or injury to the back and muscles. This may involve using lifting aids or getting assistance from others when moving or positioning the coils. Secondly, aluminum coils can have sharp edges or corners, which can cause cuts or puncture wounds if not handled carefully. It is advisable to wear appropriate personal protective equipment, such as gloves, when handling the coils to protect against any potential injuries. Additionally, aluminum is a highly conductive material for electricity and heat. Therefore, it is crucial to ensure that the coils are not in contact with any live electrical sources or exposed to open flames or intense heat. This can help prevent electrical shocks or fires, which could pose significant safety risks. Furthermore, proper storage and stacking of aluminum coils is essential to prevent accidents. Coils should be stored in a stable and secure manner, ensuring that they are not at risk of falling or rolling over. Proper stacking techniques, such as using appropriate supports or pallets, should be employed to prevent them from toppling over. Lastly, it is important to be aware of any specific safety guidelines or regulations provided by the manufacturer or relevant authorities when handling aluminum coils. Following these guidelines can help ensure the safe handling and use of the coils and minimize the risk of accidents or injuries. In conclusion, the safety considerations when handling aluminum coils include using proper lifting techniques, wearing personal protective equipment, avoiding contact with electrical sources and heat, ensuring proper storage and stacking, and following manufacturer guidelines. By taking these precautions, the risk of accidents or injuries can be significantly reduced.

- Q: This question is asking for a comparison of various types of aluminum coils, highlighting their unique characteristics and uses.

- <p>Aluminum coils are differentiated by their thickness, alloy composition, surface treatment, and temper. Common types include 1000 series coils with high purity, 3000 series known for formability, 5000 series for corrosion resistance, and 6000 series for strength. Thickness varies from thin gauges used in packaging to thick ones for construction. Surface treatments can include anodizing, painting, or lacquering for enhanced properties. Temper refers to the hardness and strength, with 'H' for hard and 'O' for soft tempers. Each type serves specific industries, such as automotive, aerospace, construction, and packaging.</p>

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. Aluminum is a popular choice for condenser coils due to its excellent heat transfer properties, durability, and resistance to corrosion. Additionally, aluminum coils are lightweight, making them easier to install and transport.

- Q: What are the pros and cons of utilizing aluminum coils in storage applications?

- <p>Aluminum coils offer several advantages for storage, including high durability, corrosion resistance, and lightweight properties which make them easy to handle. They are also recyclable and have good thermal conductivity, which can be beneficial in temperature-controlled environments. However, there are downsides such as higher initial costs compared to some other materials and potential for denting or damage if not properly handled. Additionally, while aluminum is generally non-magnetic, it can be attracted to strong magnets, which might be a consideration in certain storage scenarios.</p>

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight, strong, and corrosion-resistant properties. It is an ideal choice for fuel tanks as it can effectively withstand the harsh conditions and requirements of aircraft operations.

- Q: This question asks about the duration an aluminum coil can last before it needs to be replaced or becomes unusable.

- <p>The lifespan of an aluminum coil can vary significantly depending on its application, quality of the material, and environmental conditions. Generally, if properly stored and used, aluminum coils can last for several years without significant degradation. However, in industrial settings where coils are subjected to continuous use and harsh conditions, their lifespan might be reduced to a few years or even less. Regular maintenance and inspection can help extend the lifespan of aluminum coils.</p>

- Q: How are aluminum coils protected against corrosion?

- Various methods are utilized to protect aluminum coils from corrosion. One prevalent approach involves applying a protective coating or finish to the coil's surface. This coating acts as a barrier, preventing the aluminum surface from coming into contact with moisture, oxygen, and other potentially corrosive elements present in the surroundings. The coating can take the form of a layer of paint, anodizing, or a specialized protective film. Another technique employed to safeguard aluminum coils from corrosion is alloying. By incorporating small quantities of other metals such as copper or zinc into the aluminum, the corrosion resistance of the alloy is enhanced. These alloyed metals create a protective oxide layer on the aluminum's surface, serving as a shield against corrosion. In addition to coatings and alloying, proper cleaning and maintenance of aluminum coils are essential for corrosion prevention. Regular cleaning helps eliminate any contaminants or corrosive substances that may have accumulated on the coil's surface. This ensures the integrity and effectiveness of the protective coatings or oxide layers in preventing corrosion. Furthermore, the proper installation and sealing of aluminum coils are imperative for corrosion protection. Effective sealing prevents moisture or other corrosive agents from infiltrating the interior of the coil, which can result in corrosion over time. Overall, a combination of protective coatings, alloying, regular cleaning, and proper installation techniques plays a crucial role in safeguarding aluminum coils against corrosion. This ensures their durability and optimal performance.

- Q: Is it possible to create a baking pan using aluminum coil material?

- <p>Yes, you can use aluminum coil to make a baking pan. Aluminum is a popular material for baking pans due to its excellent heat conductivity, which allows for even heating. When creating a baking pan from aluminum coil, ensure that the coil is food-grade and that the edges are properly sealed to prevent any sharp edges. It's also important to consider the thickness of the aluminum, as a thicker gauge will distribute heat more evenly. Always follow safety guidelines and ensure that the aluminum coil is suitable for use in an oven.</p>

Send your message to us

Royal Brown Aluminum Coil - Aluminum Mill Finished Coils 8xxx for Constructions

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 100000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords