Colored Aluminum Foil - Aluminum Foils & Aluminium Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

2.Why you choose us?

Our quelity and service is best in China!

3.Specification and Application

ALUMINIUM FOIL

ALLOY:AA1***

AA3***

AA8***

TEMPER: O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

LIGHT GAUGE ALUMINUM FOIL

application:cigarette package, aseptic package, pouches, sachets

alloy:1235/8011/8079

temper:O

thickness&tolerance:0.006mm-0.009mm (±6%)

width&tolerance: 200mm-1650mm (±1mm)

mehanical properties: tensile strength (U.T.S)≥40Mpa, elongation≥1%

standard: GB/T3198 / ASTM-B209 /EN 546

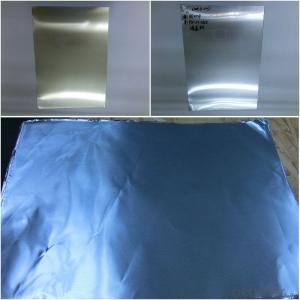

4.Pictures

5.FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

Production Flow of Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: Can aluminum foil be utilized as a substitute for a pizza pan?

- <p>Yes, aluminum foil can be used to make a makeshift pizza pan. It's a good alternative when you don't have a pizza stone or pan. Simply prepare a sheet of aluminum foil, ensuring it's large enough to hold the pizza and has some overhang for easy handling. Grease the foil lightly to prevent sticking. While it won't provide the same crispiness as a stone or metal pan, it can still yield a decent pizza. Just be cautious when removing the pizza to avoid tearing it, as foil is less sturdy than a solid pan.</p>

- Q: What do you think is the best 125 dirtbike on the market right now?

- save time and money during the week by buying lean protein such as chicken breasts in bulk and cooking a weeks worth on sunday night

- Q: I am making stuffed porkchops for dinner and have never done it beforeCan I put them on a cookie sheet and cover the cookie sheet with aluminum foil or should I just place them on the cookie sheet without anything on it? How long should I bake them or better yet how will I know when they are done? I have never done this before so any suggestions will be greatThank you

- BF3 on High/Very High, it depends on your hard drive/ssdFrom that list if I were to upgrade it I would go to an Asus board, preferably with a 990 chipset and AM3+ support that way you can upgrade in the future.

- Q: has any body seen pellet guns from Mexican manufacturer propelled by a 22' blank and a lead BB as a proyecti

- First you must understand they are NOT pellet guns nor is the ammunition made to be shot from a .22 caliber pellet gunThese are actually made to be fired in .22 caliber rifles and revolvers (Will not function in semi-auto guns.) They are both manufactured in Mexico by Aguila AmmunitionThe first is a .22 long rifle cartridge with a 20 grain conical shaped bulletIt has NO powder in it and the charge is produced solely by the primer in the cartridgeThey have a limited range of about 30 ft and will penetrate one side of a steel can or both sides of an aluminum can.Low powered, but a lot of fun to plink withThe 2nd is an Aguila CB Cap that consists of a .22 caliber round lead ball, loaded into a shortened .22 caliber short casing, again with NO powder, and is also propelled by the primer only! Effective range maybe 20-30 ft maximum from a bolt action rifleThese are very inexpensive and only retail for about $1.70 per box of 50I sell many boxes of these in my shop and they are very popular, especially to adults training a child to shoot who is not ready for a full powered .22 LR cartridgeI have used these myself many times and have actually bagged squirrels with the .22LR versionsI am sure these are what you are referring toAguila does not manufacture any firearms or pellet guns, strictly .22 ammunitionNOTE Thanks Charly.You keep all of the facts to yourself and I answer your question based on what I thought you were talking about.and you give me a thumbs down.Real niceMakes me glad I wasted my time trying to help a kid.You probably wern't even born yet when this stuff was supposedly available.

- Q: The connection between the aluminum wire going to the house (Power company) and the copper wire going into the house (home owner) at the breaker box became loose, due to fifty years of operation and an overloaded main circuit (we only had 100 amps going into the house - we've since upgraded) and it caught fire. The house itself didn't burn down (thank God), but it easily could have.From asking my electrician and reading other Answers here, it seems that having Aluminum wire outside the house is pretty common - it is a bunch cheaper than copper.But aluminum wire has been implicated in a lot of fires and seems to have been the cause of this one.Do power companies really use aluminum wire the majority of the time? Is this (usually) safe? Do I have reason to raise a stink, or should I just let it go?

- Don't make a stink. Power companies typically use aluminum. There is nothing wrong with aluminum as long as the Termination or Lug that it is connected to is made for Aluminum not copper. Believe me, the power company is using the correct lugs. The other answerer does not know what he is talking about. The problem is that aluminum attached to copper causes corrosion. It is called Galvanic corrosion. Look it up. That causes the fires. Not the use of aluminum. Use the correct lugs and there is no corrosion.

- Q: When they scan my bag and see them, will they think that they might be weed or something? I know once they take them our theyll see theyre not, but ill still be really embarresedAnd are you allowed to have plants in your carry on bag, or should i put it in my suitcaseIm just afraid if i put them in my suitcase theyll get damaged.In case your wondering WHY i have two baby treesWell, im in San Fran and i went to see the Red Woods at that one parkAnd in the gift shop they sell baby red wood trees! :o the plastic tube they are in is only about 8-12 inches tall and about an inch in diameterI live all the way in Florida and im nervous traveling with themI dont wanr anything to happen to them!

- It's not often i am surprized but this video really would make anyone say wow I need to ask - do you realise there's recent discovery students around this planet are improving thier condition I learned about this from reading website take a look now search google for Diabetes Crusher Tactic

- Q: i am going to change my radiator in my older mercedes right now its got a nissens 1 tube the reason im changing is the tranny cooler but i was wondering if i can save money buying another aluminum 1 tube radiator for cheaper on ebay it is brand new and has lifetime warrantyit runs for 115 should i go for one off radiator barn for 144 lifetime warranty that is a brass tho not aluminum will that matter? what one is better to useshould i just get another nissens i believe those are more expensiveIm really trying to save money but if you think i should pay the extra 50-60 bucks should i Thanks

- super question Timinator wow for my section i want to French kiss the inventor of Chapstick lip balm adult adult males and a few ladies be attentive to how plenty extra desirable it makes as a seal around and for the lips good females

- Q: Anyone happen to know the recipe for the Buffalo Ranch Chicken Wrap or a recipe similar to it? Thanks!

- im not sure i know how to answer this more information please im dying to know what your talking about hahaha :)

- Q: I strongly dislike Halloween and have no interest in giving out candyFor one I can't afford it, and secondly I will already be giving the few kids I know treat bags ahead of time.Im thinking I will just leave the outside lights off, and close the blindsShould I put a note on the door?I thought about leaving for the night but I'm too paranoid someone will do something to my houseAny tips would be appreciated! Thanks! :)

- Give out the stupidest things (pennies, an egg, rubber band, DOUBLE sticky tape, velcro, aluminum foil)then you wont have to spend money, and its so funny to see the looks on their faces :D

Send your message to us

Colored Aluminum Foil - Aluminum Foils & Aluminium Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords