Aluminum Flat Sheets for Sale - Aluminium Sheet 1050 H32 Mill Finish with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

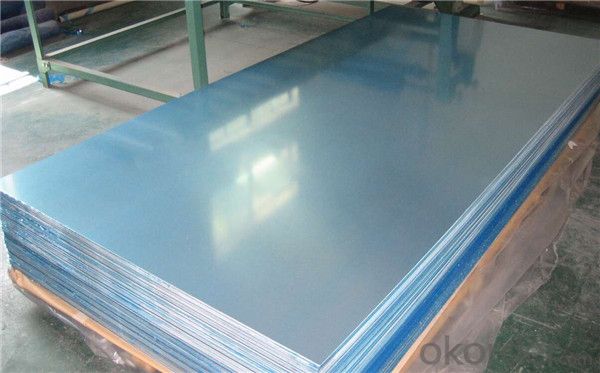

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: Can aluminum sheets be used in aerospace applications?

- Yes, aluminum sheets can be used in aerospace applications. Aluminum is a widely used material in the aerospace industry due to its excellent combination of strength, lightweight properties, and resistance to corrosion. It is used in various components of aircraft, such as the fuselage, wings, and structural panels, where weight reduction is critical for fuel efficiency and performance. Additionally, aluminum sheets can be easily fabricated and formed into complex shapes, making them suitable for various manufacturing processes in the aerospace industry.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Aluminum cans melt at about 1220 F. Lava is about 1300F to 2400F. The can would melt into the lava.

- Q: Is it possible to utilize aluminum sheets in interior design projects?

- <p>Yes, aluminum sheets can be used for interior design purposes. They are lightweight, durable, and resistant to corrosion, making them suitable for various applications such as wall cladding, ceilings, and furniture. Aluminum sheets can also be painted or anodized to achieve different finishes, adding aesthetic appeal to your design. However, it's important to consider the specific requirements of your project, such as load-bearing capacity and thermal insulation, as these properties can vary with different types of aluminum sheets.</p>

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be colored or finished in various ways to achieve different aesthetic and functional results.

- Q: Can the aluminum sheets be used for manufacturing power distribution systems?

- Yes, aluminum sheets can be used for manufacturing power distribution systems. Aluminum has excellent conductivity properties, making it a suitable material for transferring electrical power. Additionally, aluminum sheets are lightweight, corrosion-resistant, and cost-effective, making them a popular choice in the manufacturing of power distribution systems.

- Q: To an idiot, this may seem like a stupid question: its just aluminum. But it may not be.However seeing that I am only a high school student and don't have access to aluminum power (which is what I desire for an independent experiment) so I'd like to grind consumer grade aluminum foil down bases of Mohs scale of Hardness.My concern is that aluminum foil is Aluminum oxide which is a 9 (10 being diamond, 1 being talcum powder) and this would be horribly difficult to grind.If it is Alumina, that's only a 3.5.If it does happen to be aluminum oxide, can you think of a way to remove the Oxygen. Would nitric acid work.

- Aluminum foil, Commonly known as Shiny Metal Paper is actually made of Gold. The shiny side has wax on it to make it shinier, while the duller side is coated in a light dusting of diamond powder. This could be ground in a coffee machine, but I don't reccomend drinking the product of the blending. Do not microwave. Thx! Don't forget to rate best answer!

- Q: aluminum is produced by breaking down the compound...

- Bauxite is the most important aluminum ore. It consists largely of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH), and diaspore α-AlO(OH), together with the iron oxides goethite and hematite, the clay mineral kaolinite and small amounts of anatase TiO2. You have an unusual way of asking that question. Aluminum is an element and cannot be broken down accept to sub-atomic particles.

- Q: How do aluminum sheets perform in terms of thermal conductivity?

- Known for their excellent thermal conductivity, aluminum sheets are highly efficient in transferring heat due to having one of the highest thermal conductivity among common metals. This quality enables aluminum sheets to rapidly absorb and distribute heat, making them ideal for situations where heat needs to be dissipated or transferred quickly. Furthermore, their high thermal conductivity guarantees even heat distribution across the surface, reducing hot spots and improving overall heat transfer efficiency. As a result, aluminum sheets are widely acknowledged for their exceptional thermal conductivity, making them a favored option in industries such as automotive, aerospace, and electronics.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Indeed, the utilization of aluminum sheets is appropriate for the fabrication of audio speaker enclosures. Aluminum, being a lightweight and sturdy substance, is frequently employed in the manufacturing of speaker enclosures. It possesses exceptional acoustic characteristics that enable the production of precise and clear sound reproduction. Furthermore, aluminum exhibits resistance to corrosion, thereby guaranteeing the enduring lifespan of the speaker enclosure. Moreover, aluminum can be effortlessly molded and shaped into diverse designs, providing flexibility throughout the manufacturing procedure. All in all, due to their acoustic properties, durability, and versatility, aluminum sheets are an appropriate selection for the production of audio speaker enclosures.

Send your message to us

Aluminum Flat Sheets for Sale - Aluminium Sheet 1050 H32 Mill Finish with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords