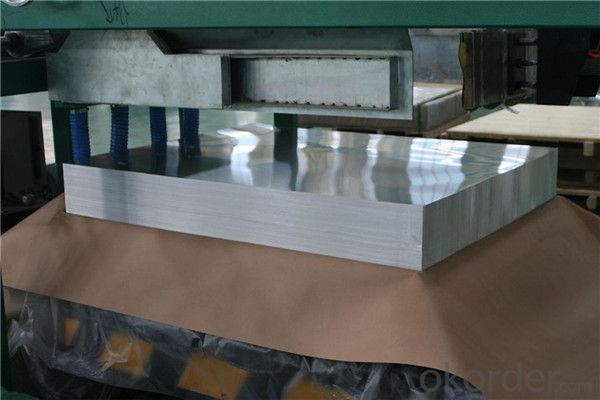

High Quality Aluminum Roof Sheets - 5052 H32 Aluminum Sheet with High Sales Volume

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | wooden cases is suitable for long distance exporting. |

Delivery Detail: | 30-45 days after receiving L/C or payment in advance |

Decorative Coil/Plate | |

Alloy: | 1100/8011/3003 |

Temper: | H16/H18/H26 |

Thickness: | 0.10mm~0.50mm |

Width: | 1000mm--1300mm |

Tensile Strength: | 155~230Mpa |

Elongation: | ≥2.0% |

T Bend: | within 2T |

PS Board Base | ||

Alloy: | 1060 | |

Temper: | H18 | |

Thickness: | 0.14mm~0.27mm | |

Width: | 300--1250mm | |

Tensile Strength: | ≥140Mpa | |

Elongation: | ≥2.0% | |

Circuit/Lighting sheet | ||

Alloy: | 1060/1100/8011/1050 | |

Temper: | H16/H18 | |

Thickness: | 0.14mm~0.50mm | |

Width: | 300--1250mm | |

Tensile Strength: | 165~195Mpa | |

Elongation: | ||

5052 sheet is a non-heat treatable alloy that is weldable. It is hardened by cold work. It has good forming characteristics and good corrosion resistance, including resistance to salt water. Commonly used in the manufacture of hydraulic tubes, kitchen cabinets, small boats, home freezers, milk crates, aircraft tube, fencing, and appliances. Commonly used in sheet metal work and in sheet metal parts.

Photos

- Q: Can aluminum sheets be used for electrical wiring?

- No, aluminum sheets are not typically used for electrical wiring. Instead, copper wires are commonly used due to their superior electrical conductivity and lower resistance. Copper wires are more efficient and safer for transmitting electrical currents.

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: What safety measures should be taken into account when installing aluminum sheets?

- <p>When installing aluminum sheets, it's important to follow safety precautions. Always wear appropriate personal protective equipment, including gloves and safety glasses. Ensure the work area is clear of debris and other hazards. Use the correct tools for cutting and handling aluminum sheets to prevent injuries. Be cautious of sharp edges and corners that can cause cuts. Ensure the aluminum sheets are properly secured to avoid them falling and causing harm. Follow all manufacturer guidelines for installation to ensure the stability and longevity of the aluminum sheets.</p>

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- To dig the Elven blood machine at the Pocket Monster Center

- Q: How do you calculate the weight of an aluminum sheet?

- To determine the weight of an aluminum sheet, one must take into account its dimensions (length, width, and thickness) as well as the density of aluminum. Initially, one should measure the length, width, and thickness of the aluminum sheet in either inches or millimeters. It is crucial to use a consistent unit of measurement throughout the calculation. Subsequently, if necessary, the dimensions should be converted to feet or meters. For instance, if the dimensions are in inches, divide each value by 12 to convert them to feet. To ascertain the volume of the aluminum sheet, multiply the length, width, and thickness together. In case the dimensions are in different units, they must be converted to the same unit before multiplying. Next, consult a reference for the density of aluminum. Aluminum's density is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, multiply the volume by 0.0283 to convert it to cubic meters. Lastly, multiply the volume of the aluminum sheet by the density of aluminum to determine the weight of the sheet. The resulting weight will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It is important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, one must calculate the weight of each section individually and then sum them to find the total weight.

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- Aluminum sheets are commonly utilized in aerospace applications because of their lightweight and high strength properties. The thickness of these sheets can vary based on the specific needs of the fabricated component or structure. Aluminum sheets in aerospace applications typically have thicknesses ranging from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm). These thicknesses are chosen considering factors such as the desired strength-to-weight ratio, structural integrity, and the specific application or component being manufactured. Thinner aluminum sheets, with a thickness of 0.016 to 0.040 inches, are frequently used for lightweight structures, interior components, and non-critical parts. These thin sheets provide the necessary strength while keeping weight at a minimum. Thicker aluminum sheets are employed for more structural components. Typically, thicknesses between 0.040 and 0.125 inches are utilized for structural elements like floor panels, bulkheads, and wing ribs. These sheets offer enhanced strength and rigidity to support the aircraft's weight and handle the stresses experienced during flight. In certain cases, even thicker aluminum sheets ranging from 0.125 to 0.25 inches may be employed for heavy-duty structural components or areas requiring additional strength. These thicker sheets are used for critical parts like landing gear components, wing spars, and engine mounts to ensure the necessary structural integrity and load-bearing capability. It is important to note that these thickness ranges are general and may vary depending on the aircraft type, design specifications, and the specific application within the aerospace industry.

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Can aluminum sheets be painted or coated?

- Aluminum sheets have the ability to be painted or coated. Aluminum, being a versatile material, can easily be painted or coated in order to enhance its appearance or improve its performance. The key to successfully painting or coating aluminum lies in adequately preparing the surface and using appropriate primers or coatings specifically designed for aluminum. To achieve this, the aluminum sheet's surface must be thoroughly cleaned, devoid of any oils, dirt, or oxidation, and may require sanding or etching to promote adhesion. Once the surface is prepared, a wide array of paints or coatings can be applied, including liquid paints, powder coatings, and anodizing. These finishes offer various advantages such as heightened corrosion resistance, improved durability, enhanced aesthetics, and even specialized properties like heat resistance or anti-microbial properties. It is crucial to seek professional advice or adhere to the manufacturer's instructions to ensure the correct application and long-lasting effects of the paint or coating on aluminum sheets.

Send your message to us

High Quality Aluminum Roof Sheets - 5052 H32 Aluminum Sheet with High Sales Volume

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords