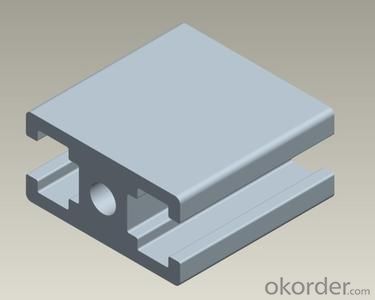

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

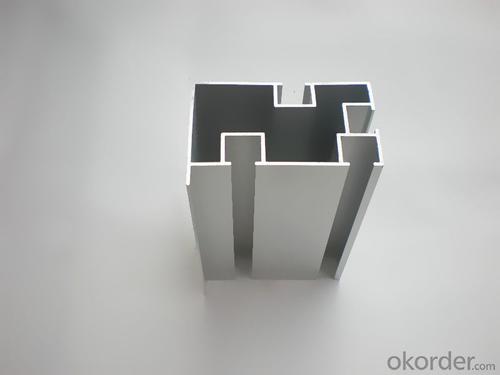

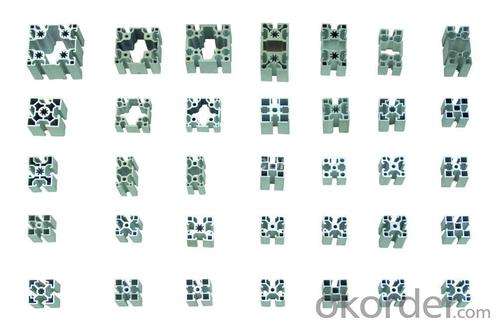

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: Request recommended professional aluminum manufacturer?

- Jing Long aluminum, aluminum strip and aluminum wafer production capacity of 60000 tons, this piece in Shangqiu, still have the strength, is a professional production and processing, wholesale distribution of aluminum, hot-rolled plate, hot rolled plate, aluminum plate, aluminum plate, roll spindle is the main.

- Q: Are aluminum profiles resistant to impact?

- Yes, aluminum profiles are generally resistant to impact due to their inherent strength and durability.

- Q: What is the opening section of aluminum profile?

- Aluminum has an outer outline, an open outline, a closed outline, a plane to cut the opening, the plane is cut.Aluminum: aluminum, made from aluminum and other alloy elements. It is usually processed into casting, forging, and foil, plate, strip, tube, rod, section bar, etc., and then made by cold bending, sawing, drilling, assembling and coloring. The main metal element is aluminum, which is added with some alloying elements to improve the performance of aluminum. Aluminum products classification: rolling material, casting material, non heat treatable alloy, pure Aluminum Alloy (1 * * * Series), Al Cu alloy (2 * * * Series), aluminum manganese alloy (3 * * * Series), aluminum silicon alloy (4 * * * series of aluminum magnesium alloy (,) 5 * * * Series), aluminum magnesium silicon alloy (6 * * * Series), Al Zn Mg alloy (7 * * * Series), aluminum alloy and other elements (8 * * * series).

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: What are the features of the poor aluminum profiles?

- Poor quality aluminum profile:1, chemical composition unqualified, seriously endanger the safety of construction projects.2 、 profile corrosion resistance function is low.3, the film thickness is thin. The national standard rules of construction of aluminum oxide film thickness not less than 10um (m). The thickness is not enough, aluminum looks easy to rust and corrosion. Some no name and address, production license, certificate of inspection in the aluminum oxide film, the thickness of only 2 to 4um, some even without film.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- In order to achieve proper electrical grounding with aluminum profiles, it is necessary to follow a few essential steps. To begin with, it is crucial to ensure the cleanliness and freedom from dirt, dust, or oxidation of all aluminum profiles. This can be accomplished by utilizing an appropriate cleaning agent or solvent to eliminate any contaminants that may impede the grounding process. Subsequently, the utilization of conductive hardware, such as grounding clips or brackets specifically designed for aluminum profiles, can enable the attainment of proper electrical grounding. These hardware components must be securely affixed to the aluminum profiles to establish a dependable electrical connection. Moreover, establishing a robust electrical connection between the aluminum profiles and the grounding system is of utmost importance. This can be accomplished by employing copper or aluminum grounding conductors that are appropriately sized and firmly connected to both the aluminum profiles and the grounding system. Additionally, it is essential to conduct regular inspections of the grounding system to ensure its effectiveness. This may involve scrutinizing for any loose connections, indications of corrosion, or damage to the grounding conductors. Any identified issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is advisable to consult with a qualified electrician or engineer who specializes in electrical grounding when dealing with aluminum profiles. They can offer specific guidance and guarantee compliance with pertinent electrical codes and standards to ensure the proper and safe grounding of the system.

Send your message to us

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords