Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil AA3003 for Decoration

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminium Coil AA3003 for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil AA3003 for Decoration

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

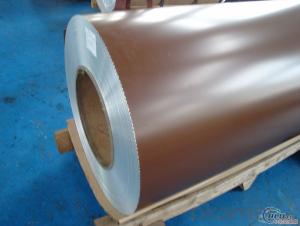

5. Image of Color Coating Aluminium Coil AA3003 for Decoration

6. Package and shipping of Color Coating Aluminium Coil AA3003 for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to recycle aluminum coils in various countries around the world?

- <p>Yes, aluminum coils can be recycled in many countries around the world. Recycling aluminum is a global practice due to its high value and the energy savings associated with recycling compared to producing aluminum from raw materials. Different countries have their own recycling programs and facilities that handle aluminum waste, including coils. However, the specific regulations and processes for recycling aluminum coils can vary by country, and it's important to check local recycling guidelines to ensure proper disposal and recycling.</p>

- Q: Can aluminum coils be used in the production of consumer goods?

- Yes, aluminum coils can be used in the production of consumer goods. Aluminum is a versatile and lightweight material that offers several advantages for consumer goods manufacturing. It is highly corrosion-resistant, making it suitable for products that are exposed to moisture or outdoor elements. Additionally, aluminum coils can be easily formed and shaped, allowing for customization and efficient production processes. Aluminum is commonly used in various consumer goods such as kitchen appliances, automotive parts, packaging materials, and electronic devices. Its properties make it an ideal choice for manufacturers looking to produce durable, high-quality consumer goods.

- Q: Would an SS scribe scratch an aluminum plate? What is the hardness value of both metals?

- It depends. If you are talking about pure Al, then yes, any SS alloy is harder than pure Al. However... There are a huge range of stainless steel alloys and they can be processed in ways which produce a large range of hardness. Similarly, there are a huge range of Al alloys with a huge range of hardness values. If you are really interested in hardness values, you need to be specific about which materials you are talking about.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are commonly used in the canning industry as they are lightweight, durable, and provide excellent sealability, ensuring the freshness and preservation of the contents.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: What are the potential applications of stucco-embossed aluminum coils?

- Stucco-embossed aluminum coils have a wide range of potential applications due to their unique properties and aesthetic appeal. Here are some potential applications of stucco-embossed aluminum coils: 1. Building and construction: Stucco-embossed aluminum coils are commonly used in the construction industry for cladding and roofing purposes. The textured surface of the stucco pattern enhances the durability and strength of the aluminum, making it suitable for exterior applications. It can be used on commercial and residential buildings to provide a visually appealing and long-lasting finish. 2. Insulation: Stucco-embossed aluminum coils can also be used for insulation purposes. The textured surface helps to increase the surface area, which improves the thermal conductivity of the material. This makes it an ideal choice for applications where heat transfer needs to be controlled, such as in HVAC systems or refrigeration units. 3. Appliances: Stucco-embossed aluminum coils are commonly used in the manufacturing of various appliances. The textured surface not only adds visual interest but also provides a durable and easy-to-clean finish. It can be used for the production of kitchen appliances like refrigerators, dishwashers, and ovens, as well as for other household appliances such as air conditioners or water heaters. 4. Transportation: Stucco-embossed aluminum coils find applications in the transportation industry as well. The textured surface provides improved traction, making it suitable for flooring and decking in vehicles like buses, trains, and ships. It is also used for decorative purposes in the interior and exterior parts of automobiles, giving them a stylish and modern look. 5. Packaging: Stucco-embossed aluminum coils can be utilized in the packaging industry as well. The textured surface adds strength and rigidity to the material, making it ideal for manufacturing containers, trays, and packaging materials that require durability and protection. It can be used for food and beverage packaging, pharmaceutical packaging, and various other applications where a strong and visually appealing packaging solution is needed. Overall, the potential applications of stucco-embossed aluminum coils are diverse and versatile. From construction to insulation, appliances to transportation, and packaging to various other industries, the unique properties and aesthetic appeal of stucco-embossed aluminum make it a popular choice for a wide range of applications.

- Q: Hello, I'd like to ask you a question. Can the aluminum coil be continuously pressed and cooled by kerosene?

- It's better not to use 0#. I'm sorry, I didn't see it a few days ago

- Q: How do aluminum coils compare to copper coils in terms of performance?

- Aluminum coils and copper coils serve as two commonly used types of heat exchanger coils within heating, ventilation, and air conditioning (HVAC) systems. Although both materials effectively transfer heat, they differ in terms of performance. Due to its superior heat transfer properties, copper coils have long been the favored option for HVAC systems. Copper possesses excellent heat conductivity, enabling efficient thermal energy transfer. Consequently, copper coils effectively cool or heat the surrounding air, resulting in quicker and more efficient temperature control. Conversely, aluminum coils exhibit lower heat transfer efficiency compared to copper coils. Aluminum proves to be a poorer heat conductor, necessitating a larger surface area to achieve the same level of heat transfer as copper. Consequently, aluminum coils tend to be larger in size to compensate for their inferior heat transfer capabilities. However, aluminum coils possess certain advantages over copper coils. Firstly, aluminum boasts a lightweight nature, facilitating easier handling and installation. This proves particularly beneficial in situations where weight restrictions or handling limitations are present. Secondly, aluminum coils display greater resistance to corrosion in comparison to copper coils. Copper is susceptible to corrosion over time, especially in environments with high humidity or exposure to specific chemicals. In contrast, aluminum naturally forms a protective oxide layer, which aids in corrosion prevention. This results in longer-lasting coils and a reduced likelihood of refrigerant leaks. In conclusion, while copper coils offer superior heat transfer capabilities, aluminum coils possess their own benefits, such as lighter weight and enhanced corrosion resistance. Ultimately, the choice between aluminum and copper coils depends on the specific requirements of the HVAC system, including desired performance, budget, and environmental factors.

- Q: How are aluminum coils processed and fabricated?

- Aluminum coils go through a series of steps to transform them into desired forms for various uses. Typically, the process includes the following steps: 1. Manufacturing Coils: Aluminum coils are initially made by melting aluminum ingots and casting them into large, flat coils. These coils are then rolled through rolling mills to achieve the desired thickness and shape. 2. Cleaning Coils: After rolling, the coils undergo a cleaning process to eliminate any dirt, oil, or impurities that may have accumulated during manufacturing. This is usually done using chemical cleaning agents or mechanical scrubbing techniques. 3. Annealing Coils: Annealing is a heat treatment process where the coils are heated to a specific temperature and slowly cooled. This process helps to relieve internal stresses, enhance the coil's mechanical properties, and improve its formability. 4. Slitting Coils: In this step, the large coils are cut into narrower strips or sheets of desired widths. A slitting machine is used to accomplish this, allowing for better material utilization and ensuring the coils meet the required dimensions for further processing. 5. Treating Coil Surfaces: Aluminum coils often undergo surface treatments to enhance their appearance, improve corrosion resistance, or provide additional protection. Common treatments include anodizing, painting, or applying a protective coating. 6. Fabricating Coils: Once cleaned, annealed, and treated, the coils can be further processed into various shapes and forms. Common fabrication techniques include stamping, bending, deep drawing, roll forming, welding, and machining. These processes allow for the transformation of aluminum coils into components such as sheets, plates, tubes, profiles, or intricate designs. 7. Controlling Quality: Throughout the entire processing and fabrication stages, strict quality control measures are implemented to ensure that the final products meet the required specifications and standards. Regular inspections and tests for mechanical properties, dimensional accuracy, surface quality, and other relevant parameters are conducted. In summary, the processing and fabrication of aluminum coils involve a combination of metallurgical, mechanical, and chemical processes. These processes aim to enhance the properties of aluminum, improve its formability, and create a wide range of products for various industries such as automotive, construction, aerospace, and packaging.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- Much less smelting required to convert pure aluminum into aluminum ingots than is needed to process boxite(?) into aluminum ingots.

Send your message to us

Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords