Aluminum Britetread Sheets 10 - AA3XXX Mil Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA3xxx Mil Finished Aluminum Sheets Used for Construction Description

AA3xxx Mil Finished Aluminum Sheets Used for Construction one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA3xxx is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of AA3xxx Mil Finished Aluminum Sheets Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

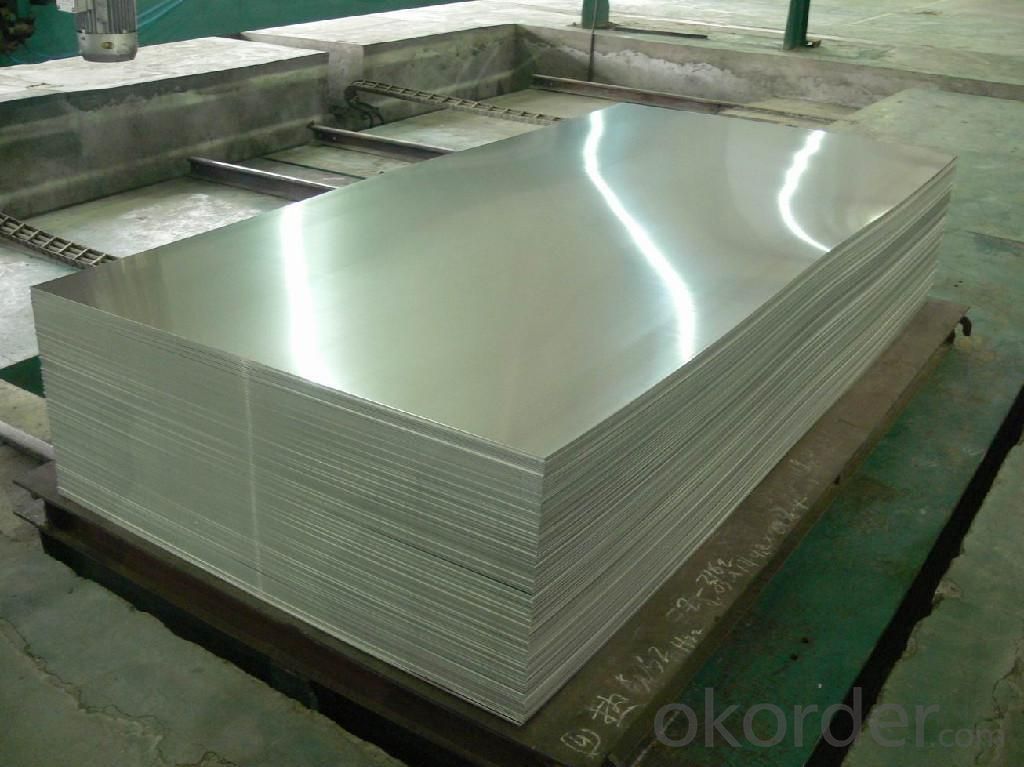

3.AA3xxx Mil Finished Aluminum Sheets Used for Construction Images

4.AA3xxx Mil Finished Aluminum Sheets Used for Construction Specification

Alloy | AA3xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mil Finished Aluminum Sheets Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- One effective way to prevent oxidation of exposed edges of aluminum sheets is by applying a protective coating or sealant. This creates a barrier between the aluminum and the surrounding air, preventing the metal from coming into contact with oxygen and moisture, which are the main causes of oxidation. Additionally, storing the aluminum sheets in a dry and controlled environment can also help minimize the risk of oxidation.

- Q: This question asks for the steps to take in order to accurately measure the dimensions of an aluminum sheet before purchasing one.

- <p>To measure the dimensions of an aluminum sheet for purchase, first, ensure you have a measuring tape or a ruler. Measure the length and width of the sheet from one corner to the opposite corner, making sure to measure along the longest and widest sides. Record these measurements in the same unit of measurement used by the supplier (commonly inches or centimeters). If the sheet is not a perfect rectangle, measure the diagonal to confirm the dimensions. Note any irregularities or variations in thickness that might affect the intended use. Once you have these measurements, compare them with the available options from the supplier to select the appropriate size.</p>

- Q: How does the surface cleanliness of aluminum sheet affect its adhesion properties?

- The surface cleanliness of aluminum sheet has a significant impact on its adhesion properties. The presence of contaminants, such as dirt, grease, or oxide layers, on the surface can hinder the ability of adhesives to bond effectively with the aluminum sheet. A clean and properly prepared surface is essential for achieving strong adhesive bonds. When the aluminum sheet is free from contaminants, the adhesive can spread evenly and make intimate contact with the surface, resulting in a stronger bond. On the other hand, if the surface is not clean, the adhesive may not be able to adhere properly, leading to weak or unreliable bonds. In addition to contaminants, the presence of oxide layers on the aluminum surface can also affect adhesion properties. Aluminum naturally forms an oxide layer when exposed to air, which can hinder adhesive bonding. This oxide layer needs to be removed or modified to ensure good adhesion. Surface preparation methods like cleaning, degreasing, and treating with chemical solutions can help remove or modify the oxide layer, allowing for better adhesion. Various surface cleaning techniques can be employed to improve the cleanliness and adhesion properties of aluminum sheets. These can include mechanical cleaning methods such as abrasive cleaning or sanding, solvent cleaning, acid etching, or even plasma cleaning. Each method is selected based on the type and extent of contamination present on the surface. In summary, the surface cleanliness of aluminum sheet directly affects its adhesion properties. A clean and properly prepared surface ensures better adhesion by allowing the adhesive to make intimate contact with the aluminum sheet. Therefore, it is crucial to consider and address surface cleanliness when attempting to achieve strong and reliable adhesive bonds with aluminum sheets.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Indeed, it is possible to paint or coat aluminum sheet after it has been fabricated. Aluminum, being a versatile material, lends itself easily to being painted or coated in order to improve its appearance or provide extra protection. The procedure involves preparing the surface through thorough cleaning and the elimination of any impurities, followed by the application of a primer to enhance adhesion. Once the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The choice of paint or coating will depend on the intended usage and the specific requirements of the application. All in all, painting or coating aluminum sheet after fabrication is a widespread practice that can significantly enhance its aesthetics and durability.

- Q: What is the flexural modulus of aluminum sheets?

- The flexural modulus of aluminum sheets refers to the measure of the stiffness or rigidity of the material when subjected to bending or flexural stress. It is a mechanical property that quantifies how well an aluminum sheet can resist deformation under applied force. The flexural modulus of aluminum sheets typically ranges between 69 GPa (gigapascals) to 79 GPa, depending on the specific alloy and temper. However, it is important to note that the flexural modulus can vary slightly based on factors such as thickness, heat treatment, and manufacturing processes. Aluminum is known for its excellent strength-to-weight ratio, making it a popular choice for various applications where lightweight and durable materials are required. Its relatively high flexural modulus allows aluminum sheets to maintain their shape and resist bending or flexing, making them suitable for uses such as aircraft structures, automotive components, and building construction. It is worth mentioning that the flexural modulus of aluminum can be enhanced by alloying elements or through heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their increased strength and stiffness properties. In conclusion, the flexural modulus of aluminum sheets is an important mechanical property that determines their ability to withstand bending or flexural stress. It provides insight into the material's rigidity and helps engineers and designers select the appropriate aluminum alloy and thickness for various applications.

- Q: What is aluminum curtain wall.

- It's more interesting to use aluminum than to say it's made of glass

- Q: Are aluminum sheets suitable for marine hulls?

- Yes, aluminum sheets are suitable for marine hulls. Aluminum is a popular choice for boat construction due to its many advantageous properties. Aluminum is lightweight, which allows for better fuel efficiency and increased speed. It is also highly resistant to corrosion, making it ideal for prolonged exposure to saltwater. Additionally, aluminum offers excellent strength and durability, ensuring the structural integrity of the hull. Moreover, aluminum can be easily formed into intricate shapes, allowing for innovative hull designs. Overall, aluminum sheets are a reliable and efficient choice for marine hulls, providing a strong and corrosion-resistant structure that enhances the performance and lifespan of the boat.

- Q: Can aluminum sheet be anodized?

- Indeed, it is possible to anodize aluminum sheet. Anodization, an electrochemical process, fortifies the natural oxide layer on the aluminum's surface, resulting in increased thickness, durability, and suitability for diverse applications. The procedure entails submerging the aluminum sheet into an electrolyte solution and passing an electric current through it. This prompts the release of oxygen ions from the electrolyte, which then combine with the aluminum, generating a fresh layer of aluminum oxide. Anodization allows for the creation of an array of colors on the aluminum sheet's surface, enhances its resistance to corrosion, and provides an improved surface for the adhesion of paints or coatings.

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

Send your message to us

Aluminum Britetread Sheets 10 - AA3XXX Mil Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords