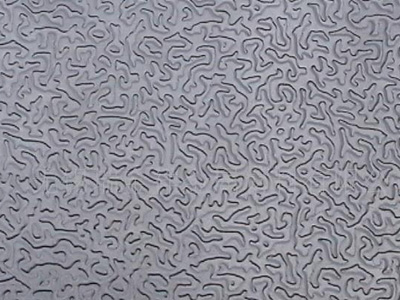

aluminium stucco sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum Stucco Embossed Sheet

1)1050/1060/1100

2)MOQ:6 Metric tons

3)300 tons sells per month

4)About 25 days of delivery

Stucco Aluminium Embossed Sheet

1.Description of Stucco Embossed Aluminium Sheet

Description | Embossed Aluminum Sheet/Coil |

Alloy | 1050; 1060;1100 ;3003; 3004;3105;5052; 6061; 6063 |

Temper | O; H18; H24; H32; H112 |

Thickness (MM) | 0.5-3.0 |

Width (MM) | 300~1600 |

Length (MM) | ≤8000 |

Application | Construction, Decoration, Automobile, Electronics, Machinery, Boat Construction, Aeronautics&Astronautics, Etc. |

2.The advantage of our Stucco Embossed Aluminium Sheet

(1) As aluminium is both a stable and durable material, it provides excellent service as a roofing or cladding without the need of any protective coating.

(2) The changes in appearance will be consistent along an elevation.

(3) Acid-corrosion-resistance, long-lasting shine, beautiful patterns, anti-corrosion performance and stability, strong adhesion, impact resistance, non-toxic side effects, safety and environmental protection.

(4) The electro-oxidation can effectively remove residual oil and manual handling of fingerprints.

(5) Embossed finish can enhance the thickness and strength of aluminum.

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is a commonly used material in the aerospace industry due to its desirable properties such as high strength-to-weight ratio, corrosion resistance, and good formability. The use of aluminum sheet for structural components allows for the construction of lightweight aircraft, which is crucial for fuel efficiency and performance. Additionally, aluminum is readily available and cost-effective, making it a popular choice for aerospace applications. However, it is important to note that the specific grade and thickness of the aluminum sheet used will depend on the particular requirements and specifications of the aerospace structural component.

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: What are the different surface finishes available for aluminum sheets?

- Aluminum sheets offer a variety of surface finishes, each with its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This is the most basic finish achieved by leaving the aluminum in its as-rolled state, without any further treatment. It has a smooth and shiny appearance, but may have slight imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and offers a wide range of color options. Anodized finishes can be matte or glossy. 3. Brushed Finish: By brushing the aluminum sheet with a fine abrasive material, a textured pattern is created. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes, giving the aluminum a high-end, mirror-like appearance. 5. Embossed Finish: Embossing involves creating raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, adding texture and visual interest to the material. 6. Powder Coated Finish: Powder coating entails applying a dry powder to the aluminum sheet and curing it under heat. This finish provides a durable and weather-resistant coating, available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting various designs or patterns onto the surface of the aluminum sheet. This finish is often used in architectural applications, adding visual interest to the material. These examples demonstrate the range of surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: How much is a square inch of a millimeter aluminum plate?

- Make a supplement to the answer on the first floorSo-called:1 lines, when referring to pure aluminum, that is, aluminum content is not less than 99%., weight 2.71 kg / square meterThe 3 Series refers to manganese as the main alloying element, that is, aluminum manganese alloy.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- Well, Al2O3 is the formula for aluminum oxide So you have 2 moles of Al, so you need 3 moles of O which is 1.5 moles of O2 So the answer is 48g

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

- Q: Can the aluminum sheets be used for roofing or siding purposes?

- Yes, aluminum sheets can be used for both roofing and siding purposes. Aluminum is a popular choice for these applications due to its lightweight nature, durability, and resistance to corrosion. It is commonly used in residential, commercial, and industrial buildings for its ability to withstand harsh weather conditions, including rain, snow, and UV rays. Additionally, aluminum is a versatile material that can be easily shaped, allowing for various design options.

- Q: This question asks for various methods through which aluminum sheets can be recycled and repurposed.

- <p>Aluminum sheets can be recycled and reused in several ways: 1. Melting and Reformation: The most common method is to melt down the aluminum and reform it into new products. 2. Mechanical Recycling: This involves shredding and compacting the aluminum sheets to be used as raw material in new products. 3. Energy Recovery: The heat generated from burning aluminum can be used to produce energy. 4. Alloying: Aluminum can be combined with other metals to create new alloys with different properties. 5. Reuse in Construction: Aluminum sheets can be reused in construction projects, such as facades or roofing. 6. Manufacturing: They can be used in manufacturing processes to create new aluminum products like cans, foils, and automotive parts. Proper recycling of aluminum reduces environmental impact and conserves resources.</p>

Send your message to us

aluminium stucco sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords