2mm Stucco Embossed Aluminum Sheet Metal Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall doors...

(2).Exterior: wall ...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminium (or aluminum; see different endings) is a chemical element in the boron group with symbol Al andatomic number 13. It is a silvery-white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal, in the Earth's crust. It makes up about 8% by mass of the crust, though it is less common in the mantle below.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

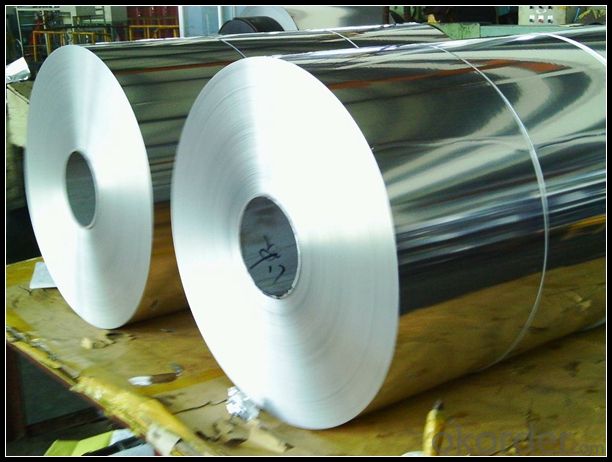

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the elements and compounds that make up aluminum strips?

- <p>Aluminum strips are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and malleable metal. Aluminum is a pure element and not a compound, so its composition is straightforward. It is found in Group 13 of the periodic table and has an atomic number of 13. In its pure form, aluminum is soft and lacks sufficient strength for many applications, so it is often alloyed with other elements such as copper, magnesium, manganese, silicon, and zinc to improve its strength and durability. These alloying elements can make up a small percentage of the total composition, but they significantly enhance the properties of the aluminum strips for various industrial uses.</p>

- Q: Is it possible to join aluminum strips together through welding?

- <p>Yes, aluminum strips can be welded. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity and reactivity. Common methods include gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), or MIG welding. These processes involve using a filler material and an inert shielding gas to prevent oxidation. Proper preparation, such as cleaning the aluminum surface and controlling the heat input, is crucial for a successful weld.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum strips in roofing systems.

- <p>Aluminum strips in roofing offer several advantages such as durability, resistance to corrosion and rust, lightweight nature, and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum strips can be easily recycled, contributing to environmental sustainability. However, there are downsides, including higher initial costs compared to other roofing materials and potential for denting if not properly installed or maintained. Aluminum can also be noisy during rain, and may require more frequent replacement due to its lighter gauge compared to some other materials.</p>

- Q: What distinguishes extruded aluminum strips from rolled ones in terms of manufacturing process and properties?

- <p>Extruded aluminum strips are formed by forcing aluminum through a die, creating a specific profile or shape. This process results in a more uniform cross-section and can produce complex profiles. Extruded strips are stronger and have better dimensional stability due to the grain flow being aligned with the direction of the extrusion. Rolled aluminum strips, on the other hand, are created by passing aluminum between rollers to achieve the desired thickness and width. This method is more suitable for producing thin, wide strips and is less costly for simpler profiles. Rolled strips may have some residual stresses and are not as strong as extruded ones, but they are more flexible and can be used in applications requiring formability.</p>

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- Not appearing in spots. Suitable for mirror surface, spray coating. Hot rolling is more expensive than cold rolling

- Q: Can welding of aluminum with water-cooled DC hydrogen arc welding machine how much money

- If the 380V is about 4500 or so, if it is pure industrial machine more than 10 thousand. This, you can go to see the semi industrial uses of 380V Classic DC argon arc welder with special industrial grade Wei Odin WSME315B inverter pulse argon arc welding of aluminum AC argon arc welding machine is a machine with three".

- Q: Explain how aluminum strips enhance the performance and durability of bicycles.

- <p>Aluminum strips contribute to bicycle performance and durability by providing a lightweight and strong material for the frame and components. Aluminum's low density reduces the overall weight of the bike, enhancing its acceleration and climbing capabilities. Its high strength-to-weight ratio allows for thinner frame walls without compromising structural integrity, which improves rigidity and power transfer from the rider to the wheels. Additionally, aluminum's resistance to corrosion and fatigue means that the bike can withstand harsh weather conditions and repeated use without significant wear and tear, thus increasing its longevity and reliability.</p>

- Q: This question asks if there are any potential health hazards linked to the use of aluminum strips.

- <p>There are some concerns regarding the use of aluminum strips, particularly in the context of cooking utensils and food packaging. Prolonged exposure to aluminum has been linked to potential health risks, including Alzheimer's disease, although the evidence is inconclusive. Aluminum can leach into food, especially in acidic environments, which may lead to increased aluminum intake. However, the FDA and other health authorities have not issued warnings about the use of aluminum cookware or food packaging, as the levels of aluminum typically ingested are considered safe. It's important to note that more research is needed to fully understand the potential health implications of aluminum exposure.</p>

- Q: The role of aluminum strip in tanks

- Using a crawler is like trying to stretch a tank indefinitely

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a wall.

- <p>To install aluminum strips on a wall, first measure and mark the area where you want to install the strips. Clean the wall surface thoroughly to ensure proper adhesion. Apply a strong adhesive or use wall anchors and screws, depending on the weight and size of the strips. Align the first strip at the bottom and press firmly to secure it. Use a level to ensure it's straight. Attach subsequent strips side by side, maintaining a consistent gap if desired. Smooth out any bubbles or wrinkles with a putty knife. Once all strips are installed, allow the adhesive to cure according to the manufacturer's instructions before handling.</p>

Send your message to us

2mm Stucco Embossed Aluminum Sheet Metal Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords